Number

Part

Product name

Description

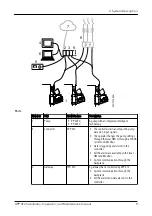

2

Controller

APP 412

• Based on process conditions, the

controller regulates the mixer.

• The operator changes the mixer settings

through the local HMI or through a SCADA

system over Modbus.

• Data is logged by and stored in the

controller.

• All the alarms are available on the local

HMI and Modbus.

• System communication through the

backplane.

3

Gateway

FPG 415

A gateway that is controlled by APP 412

• System communication through the

backplane.

• All the alarms and data are sent to the

controller.

4

HMI

FOP 402

HMI - Alternative 1

• A touchscreen HMI that is used for

navigation and selection in the menus.

• The touchscreen HMI is connected to a

web server that is embedded in the

controller.

5

HMI

FOP 315

HMI - Alternative 2

• A basic HMI with a jog wheel that is used

for navigation and selection in the menus.

6

Computer

–

HMI - Alternative 3

• The computer gives access to the same

menu system as the touchscreen HMI.

• The computer is connected to a web server

that is embedded in the controller.

7

Cloud connection

–

Cloud services

8

Connection to power –

Contactors, fuses, relays

9

Extended I/O

module

FPG 415

A gateway that is used as an extended I/O

module

2.2 Adaptive ultra-low head propeller pumps ADC

The system consists of one to eight pumps, with one APP 412 controller and

one FPG 415 gateway for each additional pump.

2 System Description

8

APP 412 Installation, Operation, and Maintenance manual