Installation, Operation, and

Maintenance manual

90001701_4.0

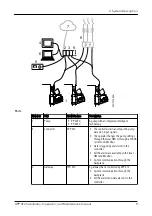

PWR

RS485

DI

1

2

3

4

GND

A

AI

AO

HMI

1

2

3

4

5

B

GND

24VDC

+

_

+

_

+

_

DI1

DI2

DI3

DI4

DO1

DO2

DO3

DO4

ALARM A

ALARM B

RUN

COMMS

RS485

USB

NODE

ADDRESS

ON

OFF

MASTER

SLA

VE

TERM

DO1

NO

COM

NO

COM

T4

T3

GND

DO2

DO3

NO

COM

NO

COM

DO4

ETHERNET

4

7

8

3

9 0

6

1

2

5

APP 412