2.

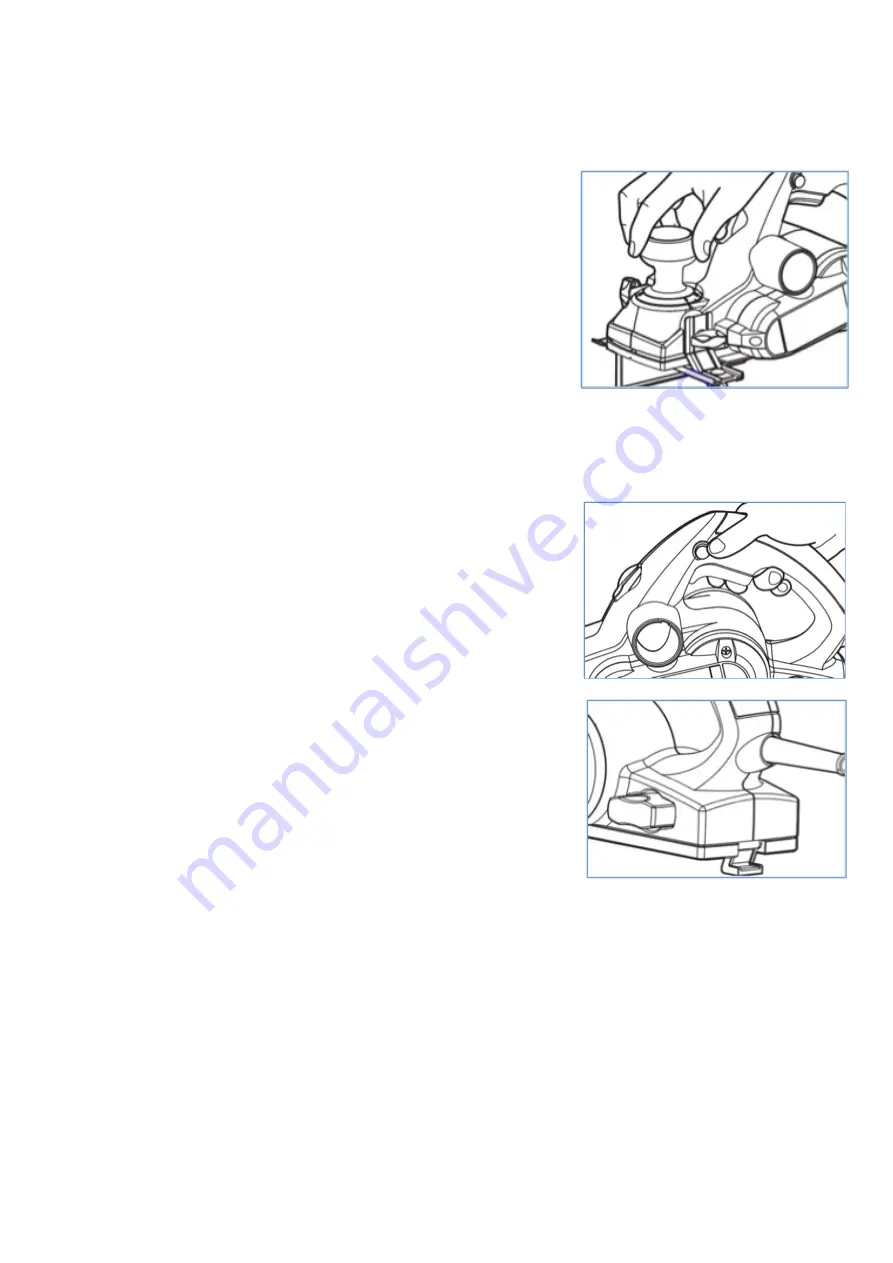

Make sure the blade sits correctly in the holder groove of the cutter drum.

3.

You may then tighten the clamping screws securing the blade and use your planer

ADJUSTING THE DEPTH OF CUTTING

CAUTION - Always ensure that the tool is switched OFF and

unplugged from the power supply before making adjustments or

installing or removing blades. Wait until the blades come to a

complete stop before adjusting the depth of the cut.

1.

Disconnect the planer from the power source.

2.

Rotate the depth adjustment knob clockwise for a deeper cut

or coun-ter-clockwise for a shallower cut.

The minimum cutting increment is 1/128” (0.2 mm).

Note: If it is necessary to accurately determine the depth of cut, plane

a scrap piece of wood, measure the difference in thickness and adjust

the settings accordingly.

CAUTION - Always ensure that the number on the ring is at the “0” position when the tool is not in use. At this

position, the blade cannot cut the workpiece.

SWITCHING ON AND OFF

CAUTION - Before plugging the machine into the power supply,

always check that the trigger switch and trigger lock work properly.

The tool is equipped with a trigger lock to avoid unintentional start-

ups. To turn the planer on, press the trigger lock and then squeeze

the trig-ger switch. To switch off, release the trigger switch.

OPERATION

1.

Check that the workpiece is held in place securely on

your work surface. Hold the planer firmly with both hands.

Rest the front shoe flat on the workpiece surface, ensuring

that the blades do not make contact with the workpiece.

2.

Switch the tool on and wait for the blades to reach full

speed.

3.

Move the tool gently forward, applying pressure on the

front of the tool at the beginning of planing, and at the rear

of the tool toward the end of the planing stroke.

4.

Push the planer beyond the edge of the workpiece without

tilting it downwards.

NOTICE: Planing is easier if you incline the workpiece slightly

away from you so that you plane “downhill”. The rate of planing and

the depth of the cut determine the quality of the finish. For rough

cutting, you can increase the depth of cut. To achieve a good finish,

you will need to reduce the depth of the cut while advancing the tool

more slowly.

NOTICE: Moving the machine too fast may cause a poor quality of

cut and can damage the blades or the motor. Moving the machine too

slowly may burn or mar the cut. The proper feed rate will depend on

the type of material being cut and the depth of the cut. Practice first

on a scrap piece of material to gauge the correct feed rate and cut-

ting dimensions.

Содержание XT106372

Страница 12: ......