Operation

CAUTION: To prevent accidents, make sure to turn the switch off and disconnect the plug from the

receptacle when the drill pits and other various parts are installed or removed. the power switch

should also be turned off during a work break and after work.

1.

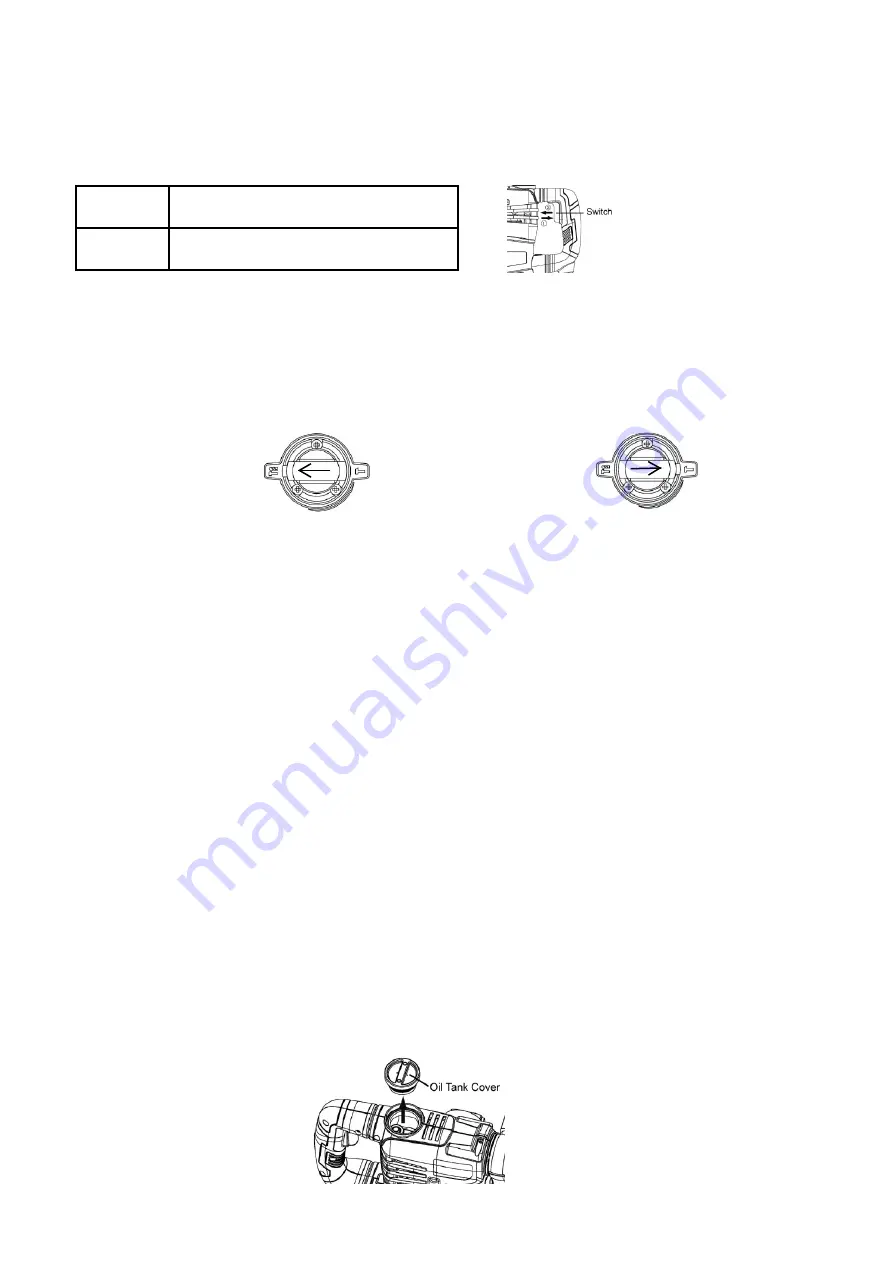

Switch operation

Swtich

ON

Press the switch towards direction

①

Switch

OFF

Press the switch towards direction

②

2.

Selecting the operating mode

Note: Chang the operating mode only when the machine is switched off!Otherwise, the machine can

be damaged.

Although this machine is equipped with a safety clutch, if the drill bit becomes bound in concrete or

other material, the resultant stoppage of the drill bit could cause the machine body to turn in

reaction. Ensure that the main handle and side handle are gripped firmly during operation.

•

Hammer drilling

3.

Setting the Speed

The Rotary hammer is equipped with an electronic control circuit. There are three speeds, the

operator can adjust the speed by pressing the speed indicator light according to the work content

.

Yellow

:

Blue

:

Green

Low speed

Intermediate speed

High speed

CAUTION:

Do not adjust the speed adjuster knob during operation. Doing so can result in injury because the

Rotary Hammer must be held by only one hand, disabling the steady control of the Rotary Hammer.

4.

How to replace grease

This machine is if full air-tight construction to protect against dust and to prevent lubricant leakage.

Therefore, the machine can be used without lubrication for long periods. Replace the grease as

described below.

CAUTION: Before replenishing the grease, turn the power off and pull out the power plug.

1. Remover the oil tank cover using a oil tank cover wrench. Wipe off the grease inside.

2. Supply 30g of Rotary Hammer Grease (Standard accessory, contained in tube) to the Crank

Housing. Too more or too little will cause the machine non-properly work.

3. Reinstall the oil tank cover and tighten with the oil tank cover wrench.

•

Hammering