18

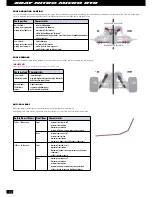

STAGE 1: SETTING THE MAIN NEEDLE SLIGHTLY RICH

Take the truck off the ground, and open the throttle fully. The engine should run cleanly until it reaches 80% of top RPM, after which it should start

to run slightly rich (4-stroking):

• If the engine runs cleanly all the way up to top RPM, richen the main needle (counter-clockwise) until it starts to 4-stroke at approximately

80% of its top RPM

• If the engine runs too rich (4-stroking all the way) lean the main needle (clockwise) until it only starts to 4-stroke at approximately 80% of its

top RPM

Adjust main

needle valve

When the main needle is properly adjusted, the engine immediately responds to the throttle operation with clean, hard acceleration without hesitation.

To check if the engine is running at a proper setting, pinch the fuel line to the carburetor and observe the results:

• At a proper setting, the engine RPM increases instantly then the engine dies out.

• If engine dies out immediately without increasing RPM, the main needle setting is too lean.

MAIN NEEDLE ADJUSTMENT

The most difficult thing to adjust is the low-speed adjustment. Keep the following principles in mind when doing this:

• Use the idle adjustment screw to adjust the idle RPM immediately after closing the carburetor.

• Use the low-speed needle to adjust the fuel mixture 2-5 seconds after closing the carburetor.

• Use only a ½ turn each way.

The low-end needle of each individual engine is precisely adjusted at the factory. The low-end needle adjusts the performance of the engine between idle up to approximately ¼

throttle. Above ¼ throttle the main needle has the most effect on engine performance.

LOW-END NEEDLE ADJUSTMENT

CARBURETOR ADJUSTMENT - BEFORE PUTTING THE TRUCK ON THE TRACK

After the engine is running and has come up to operating temperature (within 15-20 seconds) proceed as follows:

STAGE 3: SETTING THE LOW-SPEED NEEDLE

Open the carburetor for 2-3 seconds and let the engine clean out. Close the carburetor and let the engine idle.

• If the engine idles for 2-5 seconds and then the idle RPM decreases, the engine is running too rich during idle. Lean the low speed needle

(clockwise) to remedy this condition. Repeat this step until the engine idles reliably at a constant RPM for at least 20-30 seconds after the

carburetor has been opened for 2-3 seconds.

• If the engine idles for 2-5 seconds and then the idle RPM increases, the engine is running too lean during idle. Richen the low speed needle

(counter-clockwise) to remedy this situation.

• If the engine will not idle at all, rich the low speed needle (counter-clockwise), or turn the idle adjustment screw clockwise to increase the

idle RPM.

NOTE

: Because adjusting the low speed needle affects the idle RPM, use the idle adjustment screw to get the engine to idle at the right RPM.

Once you are satisfied that you have achieved reliable carburetor settings, you are ready to put your truck on the track.

STAGE 2: SETTING THE IDLE SPEED

Take the truck off the ground, and open the throttle fully for 2-3 seconds. Close the carburetor and check the idle speed that occurs immediately after.

• If the engine stops almost immediately, turn the idle adjustment screw clockwise to increase the idle RPM.

• If the idle RPM is too high, turn the idle adjustment screw counter-clockwise to reduce the idle RPM.

Adjust idle speed RPM

Adjust low-speed needle

You can only fine-tune the main needle setting at the track. Initially, the main needle should still be set a little rich. Fill the fuel tank, run the truck up to maximum speed for a few

laps, and check if it reaches top RPM without running rich towards the end (4-stroking). Lean the main needle by small increments (1/12 of a turn, like 1 hour on a clock) and run

the truck again. Repeat these small adjustments until the engine accelerates well and reaches maximum speed without running rich. It is advised to then richen the main needle

1/8 of a turn (counter-clockwise).

Running the engine too lean will cause the engine to overheat, resulting in excessive engine wear and possibly breakdown. A fast, simple way to check the engine temperature is

to apply a few drops of water to the cylinder head. The drops should evaporate only after 3-5 seconds. If they evaporate immediately the engine is too hot; richen the main needle

1/8 of a turn (counter-clockwise). Check engine temperature regularly and often.

The idle RPM and low-speed needle settings may require a little fine tuning after the main needle has been set properly. Once properly adjusted, the engine should produce a

strong, high-pitched sound at maximum speed, and a thin trail of smoke should be visible from the exhaust tailpipe.

For more information about setting the idle and low-speed needle settings, see section Carburetor Adjustment – Before Putting the Truck on the Track.

NOTE:

The carburetor settings may change with changes in weather conditions, fuel, glowplug, or exhaust system. After changing any of these, always richen the main needle

(counter-clockwise) ¼ to ½-turn and then re-adjust the main needle again on the track.

CARBURETOR ADJUSTMENT - AT THE TRACK

After your engine has been properly broken in and tuned at the track, be aware that changes in weather (temperature, humidity, barometric pressure), altitude, and fuel nitro

content will affect the performance of the engine. See the table below for guidelines on how to adjust your engine’s carburetor settings to compensate for these various changes.

FINE-TUNING THE CARBURETOR

WHEN…

DOES THIS…

CHANGE MAIN NEEDLE SETTING…

Temperature

decreases

richer

increases

leaner

Humidity

decreases

slightly richer

increases

slightly leaner

Barometric pressure

decreases

leaner

increases

richer

Altitude

lower

richer

higher

leaner

Fuel nitro content (%)

lower

leaner

higher

richer

Содержание Nitro Micro NT18MT

Страница 1: ...M I C R O...