深圳市星科创科技有限公司

Shenzhen XingKeChuang Technology Co., Ltd.

Phone: 86-0755-33523599 FAX: 86-0755-33515410 URL: http://www.sz-xkc.com

Address:

11th Floor, No. 48, Xinyu Road, Xinqiao Community, Xinqiao Street, Baoan District, Shenzhen

8

/

10

When the dynamic viscosity is less than 10mPaS, it is measured normally. 10mPaS<dynamic viscosity<30mPaS may

affect the detection. When the dynamic viscosity is greater than 30mPaS, it cannot be measured because a large amount of

liquid adheres to the container wall.

(2) Note: As the temperature increases, the viscosity decreases, and most high-viscosity liquids are more affected by

temperature. Therefore, pay attention to the influence of liquid temperature when measuring viscous liquids.

(3) Pay attention to keeping the sensor clean, try to prevent corrosion and avoid violent collisions and blows from other

objects.

(4) During outdoor installation, avoid direct sunlight and rainwater directly flowing to the main body of the sensor, and

keep away from high heat sources and pay attention to ventilation. If the ambient temperature exceeds the rated

temperature, corresponding cooling protection measures should be taken.

(5) When the ambient temperature is lower than the normal operating temperature range of the sensor, an instrument

protection box or other protective rain cap devices can be used for antifreeze protection, and pay attention to keeping the

sensor dry. The sensor should be regularly maintained and inspected. (The detection time interval is determined by the use

unit according to the specific situation).

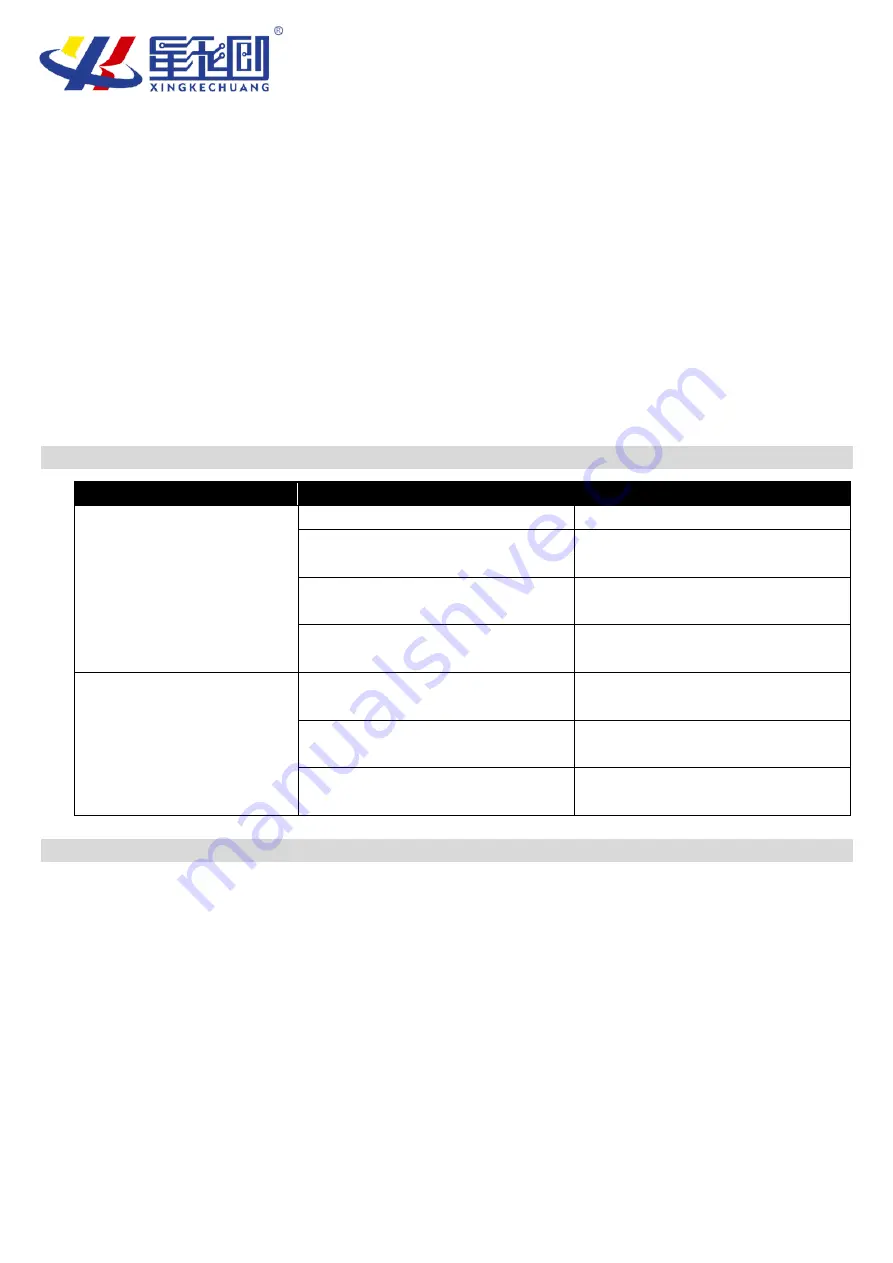

11th.Troubleshooting

Fault status

Analyze the reasons

Problem solving measures

After the liquid level sensor is

energized, there is no response

(the indicator light does not

light when the water level

reaches the sensing point, and

the sensitivity adjustment has

no response)

①

The power cord is not connected

Check and connect the power

②

The positive and negative ends of

the power cord are reversed

Correct wiring

③

The power module is damaged

Replace the circuit board where the

power module is located

④

Sensitivity is too low

Adjust

the

sensitivity

to

the

appropriate gear

The indicator light keeps on

①

Sensitivity grade is too high

Adjust

the

sensitivity

to

the

appropriate grade

②

The initialization parameters are

abnormally modified

Return to the factory to reinitialize

③

The sensor has debris or other metal

parts close to it

Clean up debris and keep a certain

distance from metal parts

12th.Product warranty terms and instructions

(A) .Warranty service

1. Warranty period maintenance: from the date of purchase, the product host has a one-year free warranty. The company

has the right to decide to repair or replace the faulty part. If it is replaced, the replacement part may be a new device or a

repair product of the same category, function, and quality. The replaced faulty part belongs to the company; the product

Resale and repair do not affect the warranty period. Products that have been repaired or replaced continue to enjoy the

original remaining warranty period service. If the warranty period is less than three months after the repair, the repaired or

replaced part shall be shipped from the date of delivery Warranty for three months; all products of the company are

guaranteed for repair.

2. Loss upon arrival (DOA) replacement: From the day of purchase, you can enjoy a free replacement service within 7

days. Products with the following problems are defined as DOA equipment: the packing and packing list do not match