18

OPERATING INSTRUCTIONS

PRE-OPERATION CHECKLIST

(OWNER/OPERATOR RESPONSIBILITY)

____ Review and follow safety rules and safety signs on

pages 3 through 12.

____ Check that Snow Blade is properly and securely

attached to tractor loader or skid steer.

____ Lubricate all grease fitting locations.

____ Check that all hardware is properly installed.

____ Check that no one enters the area of machine

operation. Always work at a safe distance from

bystanders.

____ Know your controls and how to stop power unit,

engine and PTO quickly in an emergency. READ

THIS MANUAL AND THE ONE PROVIDED WITH

YOUR POWER UNIT.

____ To avoid accident or injury, do not allow anyone to

operate this equipment without proper instructions.

Any person who operates this equipment must be

instructed in and be capable of the safe operation

of the tractor, skid steer, attachment and all

controls.

OPERATION

Be sure tractor is properly counter-balanced with

weights before attempting to operate the Snow Blade. It

is recommended to attach a heavy implement or weight

box on the 3 pt. hitch of the tractor for counter weight.

Make sure all operators have read the Owner’s Manual

and are familiar with the instructions and the safety rules

of operation.

NOTE:

• For most snow moving applications, operate with the

loader in the FLOAT position. (See your power

unit/loader manual for details on the FLOAT position.)

• For moving snow, the “A-Frame” part of the main

frame should be level. Using the bucket tilt cylinders

on your loader, tilt the main frame forward or back until

the “A” part of the frame is level.

• Blades are designed for moving snow and loose dirt.

Do not abuse blades by prying rocks or stumps with

high impact loads.

• Skid shoes should always be used for snow applica-

tions.

• When moving snow, do not operate with the blade in

the locked position.

• On skid steer models, always place blade in straight

(90°) angle position for easier dismounting and entry

to skid steer.

• Become familiar with controls.

• Operate from operator’s seat only. Remain at controls

until operating cycle is complete.

• Never lift blade to a height where visibility is obstructed.

• Avoid holes, ditches, and obstructions which may

cause tractor/loader to tip.

• Allow for additional length of loader and attachment on

power unit while turning.

• Never allow anyone to walk or work under a raised

loader.

• Be sure that people, livestock, or pets are not stand-

ing near the machine while operating.

• Carry the attachment slowly and as low as possible to

the ground.

• Operate the loader hydraulic controls smoothly, avoid-

ing jerky operation. Stop loader gradually.

• Only use a tractor or power unit equipped with a

ROPS cab or roll-over protective structure.

• Travel slowly over rough surface or when making

turns.

• Lower bucket or attachment to ground when power

unit is unattended.

OPERATE SAFELY

• Do not operate this product until you have positive

indication that this attachment is securely

mounted to the loader. Failure to install lock pins

or have the latching mechanism engaged could

result in injury or death.

• Do not exceed 10 miles per hour while operating.

• A heavy load can cause instability in driving a

power unit. Make sure the rear of the tractor is

properly counterbalanced with weights. Always

drive slowly – especially around turns. An unsta-

ble power unit could steer badly and possibly tip

over, causing injury or death.

WARNING

Содержание SBC-2160

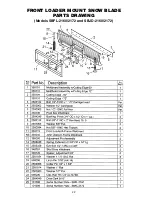

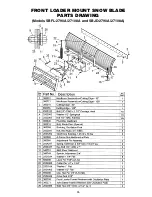

Страница 23: ...22 FRONT LOADER MOUNT SNOW BLADE PARTS DRAWING Models SBFL 2160 2172 and SBJD 2160 2172...

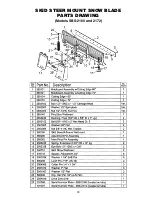

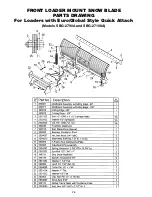

Страница 24: ...23 SKID STEER MOUNT SNOW BLADE PARTS DRAWING Models SBS 2160 and 2172...

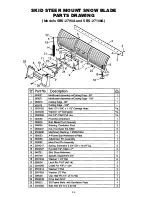

Страница 25: ...24 SKID STEER MOUNT SNOW BLADE PARTS DRAWING Models SBS 2790A and SBS 27108A...

Страница 26: ...25 FRONT LOADER MOUNT SNOW BLADE PARTS DRAWING Models SBFL 2790A 27108A and SBJD 2790A 27108A...

Страница 28: ...27 CLAMP ON LOADER MOUNT SNOW BLADE PARTS DRAWING Models SBC 2160 and 2172...

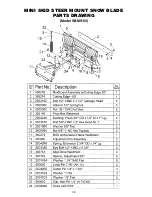

Страница 29: ...28 MINI SKID STEER MOUNT SNOW BLADE PARTS DRAWING Model SBMS 50...

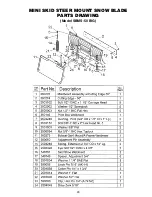

Страница 30: ...29 MINI SKID STEER MOUNT SNOW BLADE PARTS DRAWING Model SBMS 50 B G...

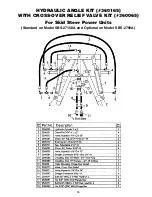

Страница 32: ...31 OPTIONAL HYDRAULIC ANGLE KIT 360165 For Skid Steer Power Units For Model SBS 2790A only...

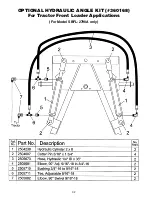

Страница 33: ...32 OPTIONAL HYDRAULIC ANGLE KIT 360168 For Tractor Front Loader Applications For Model SBFL 2790A only...

Страница 36: ......

Страница 37: ......

Страница 38: ...35 OPTIONAL MARKER KIT 360235...

Страница 39: ...NOTES...