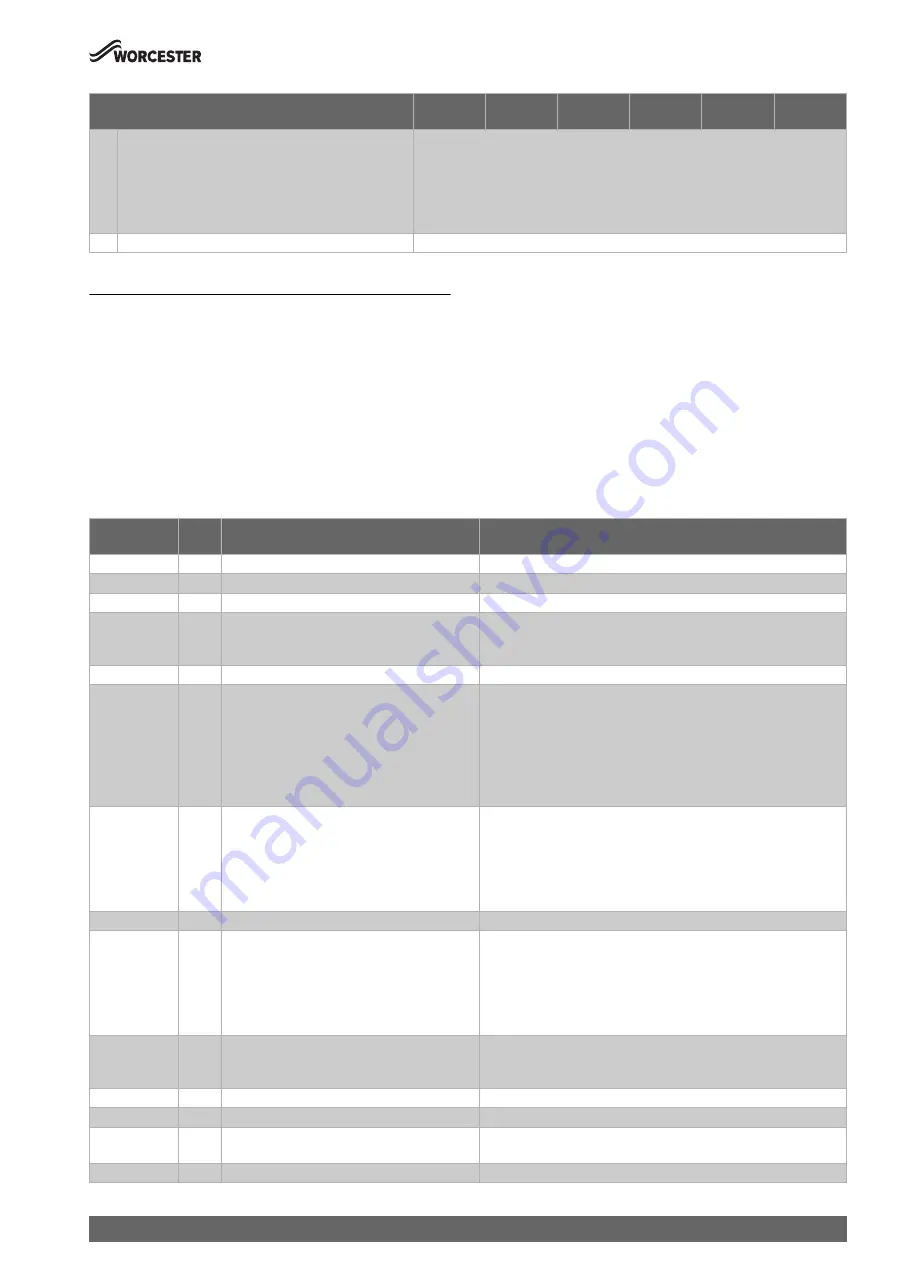

Display codes

45

Worcester Commercial Boiler Series – 6720814332 (2019/04)

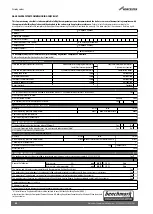

Table 17 Inspection and maintenance reports

12

Display codes

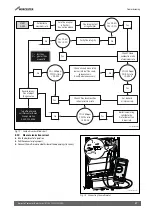

Display codes give an indication of the operating condition of the boiler.

Fault codes are either shown in the display directly or can be called up via

the information menu. Proceed as follows:

▶ Open the information menu (

Chapter 7.1).

▶ Switch to the fault code level in the information menu.

▶ Read out the fault code and look up meaning (

12.1

Code types in the display

There are 3 types of code:

▶ – Normal operating code

▶

2

Blocking fault code

▶

3

Interlocking fault code

12.2

Reset

For safety reasons, the boiler shuts down and locks as soon as a serious

fault occurs. The fault code flashes to indicate this. The boiler must be

reset in order to unlock it. Proceed as follows:

▶ Press the “reset” key (

figure 61, [2], page 31), until “rE” appears

in the display.

Generally, the boiler will operate normally again after a reset.

However, in some cases the underlying fault must first be remedied.

12.3

Operating and fault codes

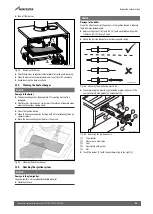

Confirm correct inspection

Company stamp/signature/date

Inspection work

Date:

___________

Date:

___________

Date:

___________

Date:

___________

Date:

___________

Date:

___________

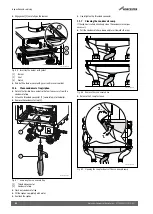

Code

Code

type

Designation

Remedy

The boiler is in chimney sweep mode.

The boiler is in heating mode.

The boiler is in DHW mode.

The boiler is waiting. There was a heat demand

from the on/off or modulating control more

frequently than 1x every 10 minutes.

The boiler is on standby.

The boiler is waiting. The actual flow temperature

is higher than the calculated or selected boiler

temperature.

▶ Check the boiler temperature on the boiler display. Increase the

above if necessary.

▶ Check the heating curve that has been set once the weather-

dependent control has been adjusted. Increase the above if

necessary.

▶ Check the wiring and function of the cylinder temperature sensor.

Replace the component if necessary.

The actual temperature recorded by the flow

temperature sensor or the safety sensor is rising

too quickly.

▶ Check the water pressure of the boiler, vent the heating system and

the boiler.

▶ Check whether it is possible to achieve sufficient flow in the heating

system.

▶ Check the operating characteristics and cabling of the pump and

corresponding sensor. Replace the component if necessary.

3

Diagnosis tool was connected.

The flow temperature sensor is not detecting a rise

in temperature following a burner start.

▶ Check the water pressure of the boiler, vent the heating system and

the boiler.

▶ Check whether it is possible to achieve sufficient flow in the heating

system.

▶ Check the cabling and operating characteristics of the pump and the

flow temperature sensor. Replace the component if necessary.

The boiler is waiting. In response to a heat

demand, the boiler regularly switches to partial

load.

Component test phase.

The boiler is modulating upwards.

The boiler is preparing for a burner start. The fan

and pump are activated.

The gas valve is switched.