14

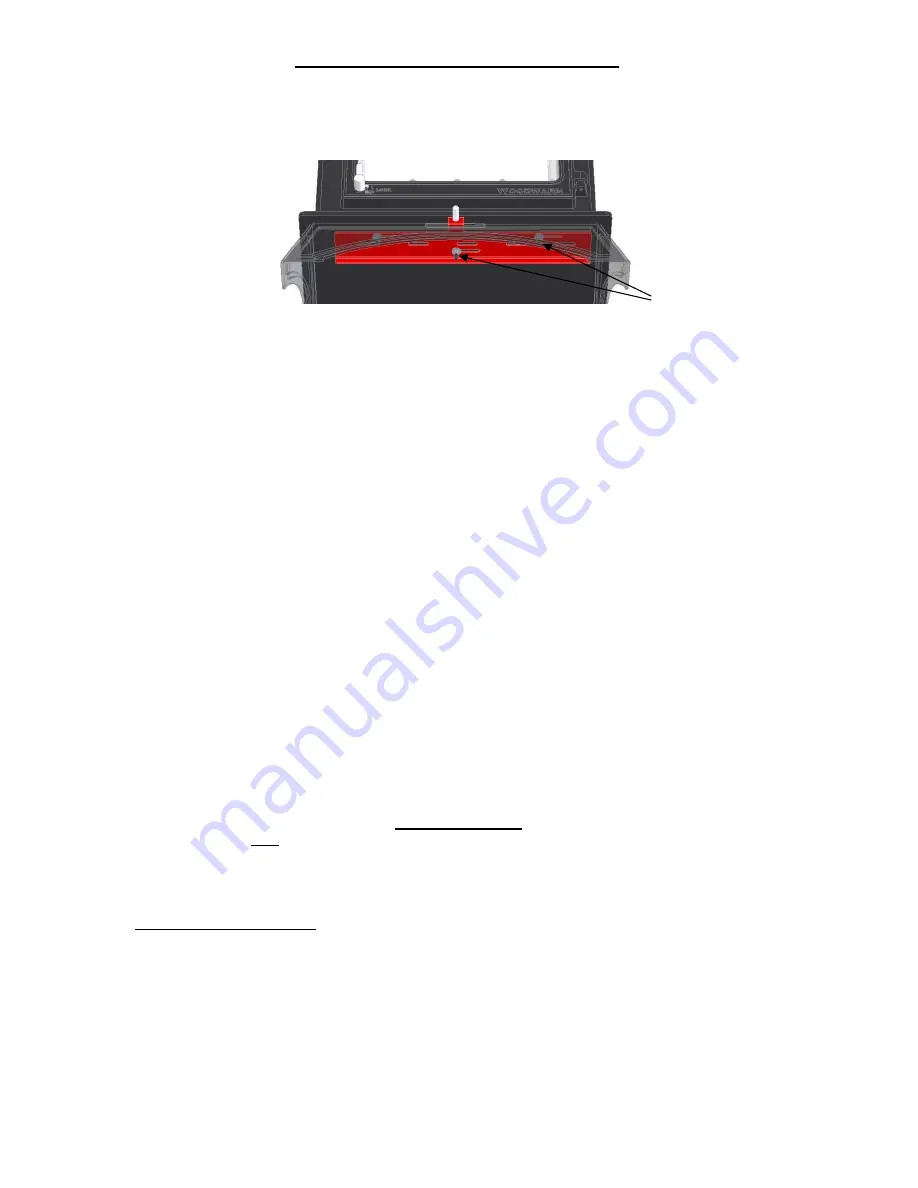

AJUSTMENT OF THE PRIMARY AIR SLIDER

Occasionally the primary air slider may require adjustment. Using a 10mm spanner you can adjust the air slider nuts

which are located underneath the base plate of the stove (diagram 9).

Caution must be taken, if the air slide is not

correctly adjusted (to loose) the stove will continue to draw in air when the air control has been shut down.

Air Slider Adjustment Nuts

Air Bleed Control

A small air bleed hole adjustment is provided, it is either located on the airwash lever, or behind it. Its function is to

allow you to “Set” the stove to the chimney draught. Open it fully and over the first couple of extended burning peri-

ods, monitor the result of your stove's slumber. If it fails to stay alight long enough, by burning through all the fuel

too quickly, reduce the setting until you are happy. When you are, tighten up the self tapping screw, so that in fu-

ture when you fully shut the airwash lever this hole will allow the stove to remain just open. Chimneys with a high

draw may require this small air bleed hole to be closed.

Chimney Fires

If the chimney is thoroughly and regularly swept, chimney fires should not occur. However, if a chimney fire does

occur turn the air control setting to the minimum, and tightly close the doors of the stove. This should cause the

chimney fire to go out in which case the control should be kept at the minimum setting until the fire in the stove has

gone out. The chimney and flue ways should then be cleaned. If the chimney fire does not go out when the above

action is taken then the fire brigade should be called immediately.

After a chimney fire the chimney should be carefully examined for any damage. Expert advice should be sought if

necessary.

Boilered Stoves Note:-

Cleanburn will be a little more difficult to achieve with boilered stoves. However perseverance to achieve as high

combustion temperatures as possible will assist in keeping the glass clean.

EXTENDED BURNING PERIODS

When burning

wood

, thus if longer burning times are required use

dry

large logs of a hard wood rather than small

ones, remembering to keep a bed of ash.

Some woods need more air than others to tick over, some experimentation will be necessary to find the right setting.

Remember

to allow the stove to reach operating temperature before closing air controls.

Plumbing notes

Please read these notes prior to installing your Woodwarm boilered stove

∗

A boilered stove will have a lower combustion temperature than a dry stove and will not reach the clean burn

state as readily.

∗

Always site the circulating pump on the return.

∗

Do not fully pump a solid fuel stove as it is refuelled on a two hour refuelling cycle and may not be able to get

it’s heat load up to temperature when fully pumped

∗

When a pump is used on the heating circuit ensure that it’s action is controlled by pipe thermostats to stop it

circulating water which is under 50°C

∗

Ensure one third of the system can rise to a gravity section of the circuit.

∗

Do not pressurize the system, always use an open vented circuit.

∗

If combining two or more heat sources think of using a “Link Up” Neutralizer as part of the circuit, it will assist

in even distribution from both heat sources.

∗

Where there are two pumps in the system, possibly as above, there will need to be a three channel

∗

programmer incorporated such as the Honeywell ST699.

∗

Do not directly plumb under floor heating into the circuit. For under floor heating there will need to be a heat

store (Thermal Accumulator, thermal store)

Diagram 9