ProAct II Actuator/Driver

Manual 04176

20

Woodward

Chapter 4.

Troubleshooting

Improper engine operation is often the result of factors other than governor

operation. This chapter gives tips about engine problems which can resemble

governor problems. Make sure the engine is operating correctly before making

any changes in the governor.

Attempting to correct engine or load problems with untimely governor adjustment

can make problems worse.

If possible, isolate the governor from the engine to determine if the problem is

with the governor and not with the engine or the load on the engine.

Governor faults are usually caused by installation problems or the linkage

between the actuator and the engine. Carefully review all the wiring connections,

the power supply, and the linkage before making any adjustments to the actuator

or driver. Always check the fuel-control linkage from stop to stop as if the

actuator were moving it. The linkage must move freely without friction and

without backlash. Some fuel controls will present problems at particular fuel or

rack position because of a hesitation or binding in the linkage.

Fuel supply and injector conditions can also present problems which resemble

governor problems.

On spark-ignited engines, distributor, coil, points, and timing problems can all

cause improper operations which may resemble faulty governor control.

Linkage and Actuator Stroke

Use as much of the 75 degrees of actuator stroke as possible. Carefully follow

the guidelines in the Actuator Installation section of Chapter 2 in making linkage

arrangements. Using less than optimum actuator movement will make stability

more difficult, and will make the actuator more sensitive to external loading

forces and friction.

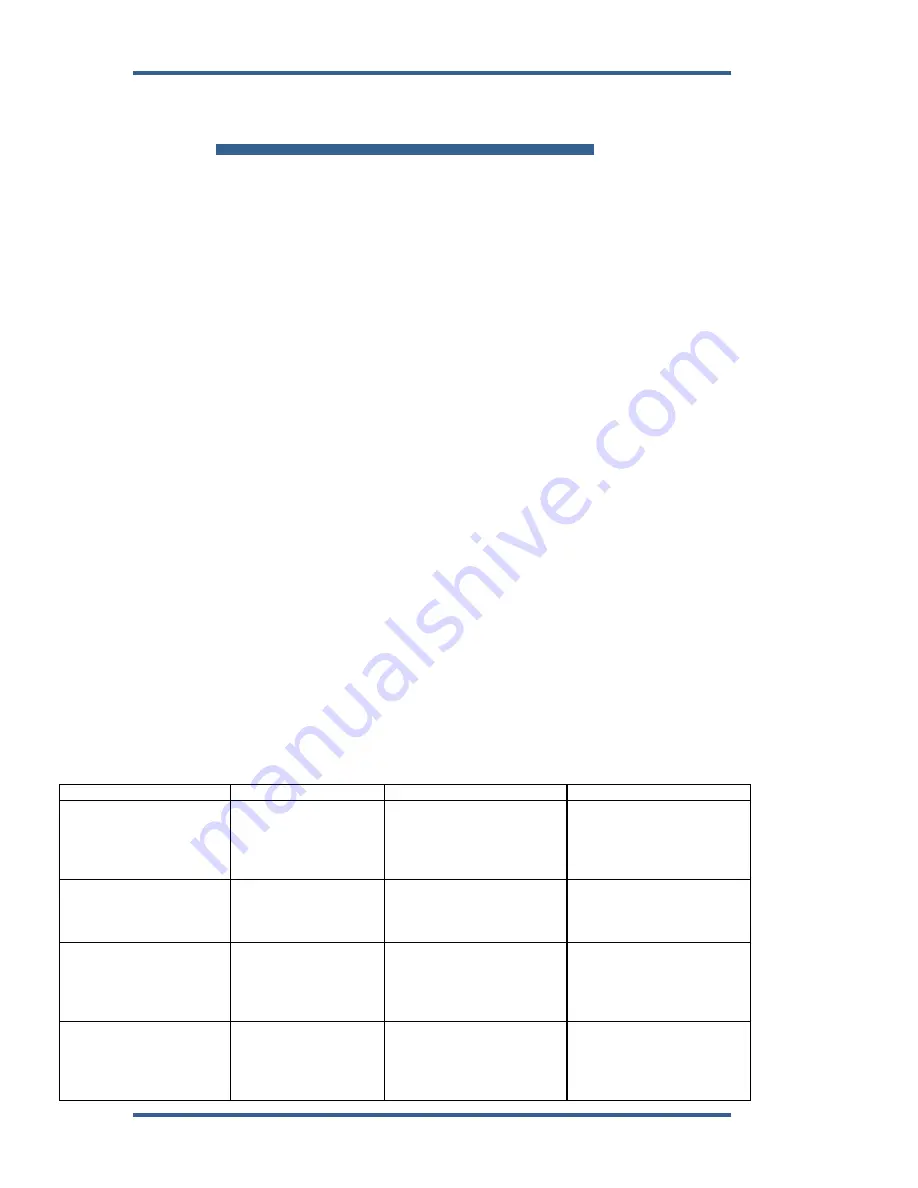

Possible problems with driver-actuator system include:

Symptom

Possible Cause

Possible Fix 1

Possible Fix 2

Actuator drives opposite

direction than the

command signal directs.

Actuator drive and

position feedback

signals are connected

incorrectly.

Actuator drive wires and

position feedback (both)

may be connected in the

reverse polarity. Check

wiring for proper polarity.

Actuator drives into max

stop with a command to

min fuel applied.

Actuator drive or

position feedback

signals are connected

incorrectly.

Actuator drive wires may

be connected in the

reverse polarity. Check

wiring for proper polarity.

Actuator position feedback

input may be connected in

the reverse polarity. Check

wiring for proper polarity.

Actuator drives into min

stop with a command to

mid fuel (or some other

non-stop command)

applied.

Position command

signal is not being

received correctly.

Position command input

leads may be connected in

wrong polarity. Check

wiring for proper polarity.

Position command input

may have poor connection

to input signal. Check

wiring for good connection.

Actuator and control

system do not respond—

all voltage outputs are 0

V.

Actuator and driver is

not receiving power.

Input power leads may be

connected in wrong

polarity. Check wiring for

proper polarity.

Input power leads may

have poor connection to

b or battery –.

Check wiring for good

connection.