-18-

Model M1112 (For Machines Mfd. Since 12/20)

SE

TU

P

5.

Rotate the red stop/RESET button (

Figure

15)

clockwise so it pops out.

6.

Make sure the spindle rotation ON/OFF lever is in

the central or neutral position (

Figure

14).

7.

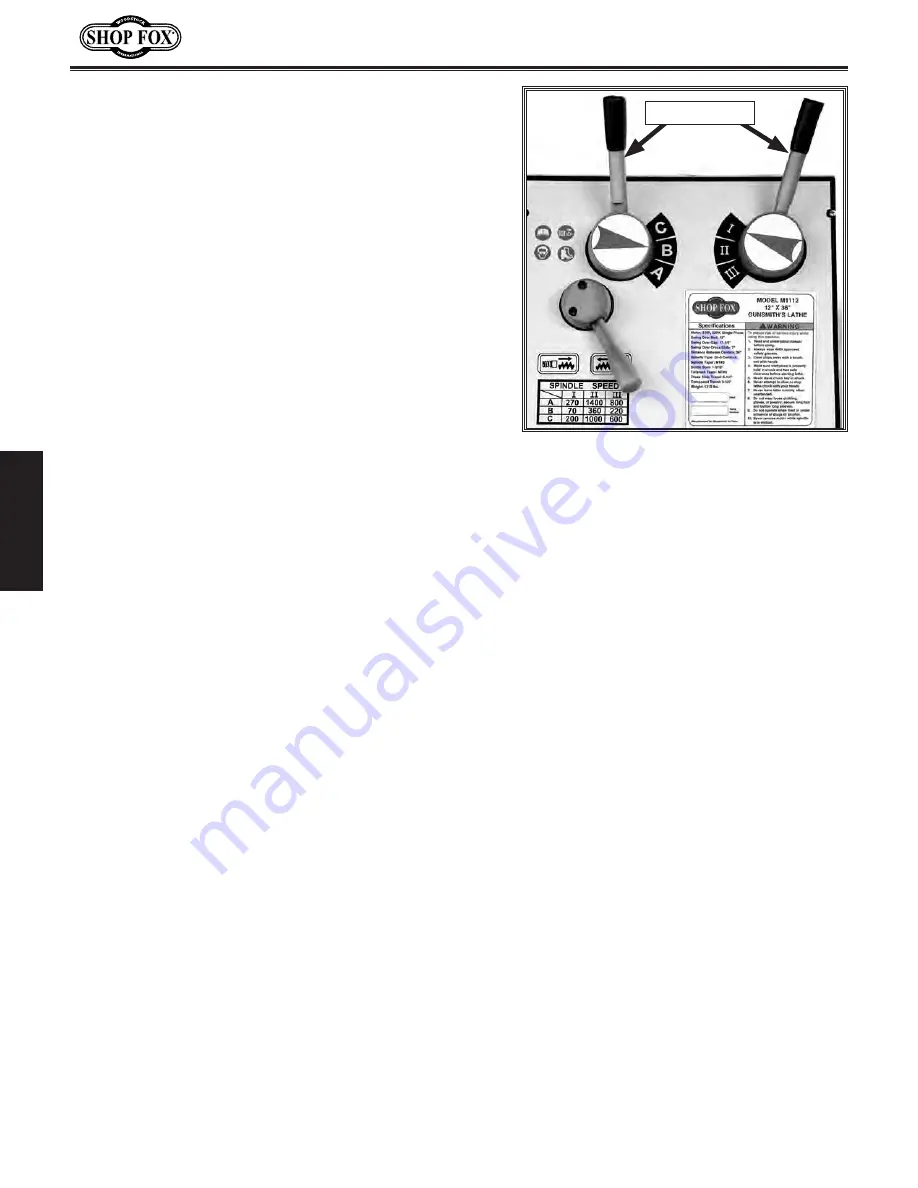

Move the speed levers to

B

and

I

so the spindle will

rotate at 70 RPM (

Figure

15).

8.

Push the POWER START button, then move the

spindle rotation ON/OFF lever (

Figure

14) down

until the chuck turns. The top of the chuck should

turn toward you.

— If you hear squealing or grinding noises, turn the

lathe

OFF

immediately and correct any problem

before further operation.

— If the problem is not readily apparent, refer to

Troubleshooting

on

Page 42

.

9.

Push the emergency stop button.

— If the lathe does not stop, turn the lathe

OFF

with

the spindle rotation ON/OFF lever, and disconnect

the lathe from power. Refer to

Troubleshooting

on

Page 42

for correction.

10.

Return the spindle rotation ON/OFF lever to STOP,

reset the emergency stop button, restart the lathe,

and let the lathe run for a minimum of 10 minutes in

both directions.

11.

Turn the lathe

OFF

, and move the speed levers to

C

and

I

so the spindle will rotate at 200 RPM. Run the

lathe in both directions for 10 minutes.

12.

Repeat

Step 9

for the remaining RPM ranges,

progressively increasing in RPM. When these steps

are complete, the lathe is broken in.

13.

Drain and refill the lubricant in the headstock with

Mobil DTE Light or ISO 32 an equivalent. Refer to

Lubrication

on

Page 39

for steps and apron oil

change interval.

Figure

15

.

Headstock controls.

Speed Levers