38

Assembly

MAN0632 (5/15/2007)

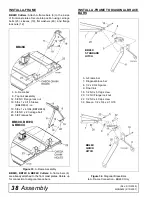

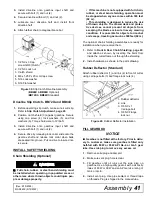

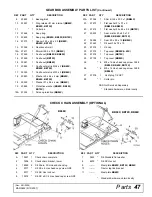

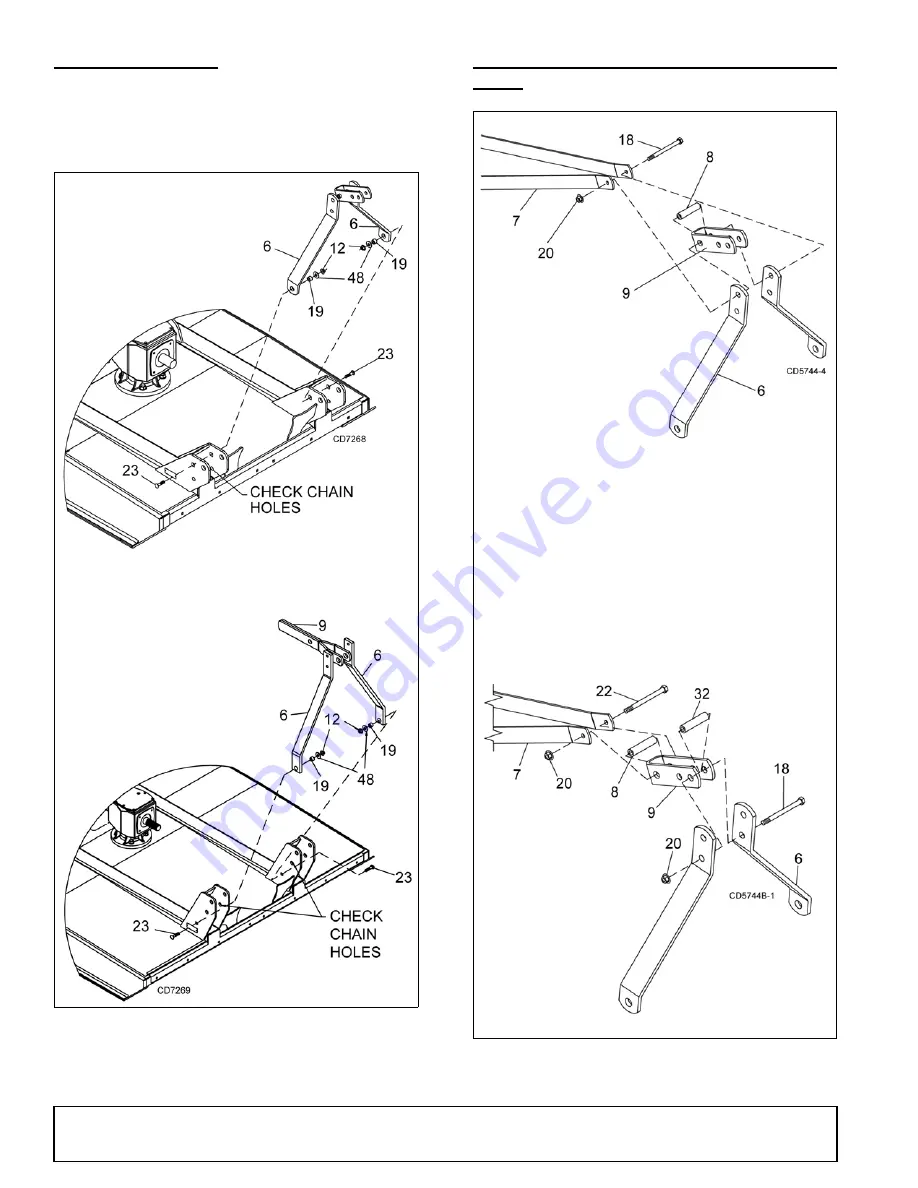

INSTALL A-FRAME

BB48X Cutters:

Attach A-frame bars (6) to the inside

of front mast plates. Secure into position using carriage

bolts (23), sleeves (19), flat washers (48), and flange

lock nuts (12).

Figure 33

. A-Frame Assembly

BB60X, BB72X & BB84X Cutters:

A-frame bars (6)

are already attached to the front mast plates. Rotate up

for connection to diagonal brace bars.

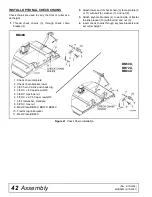

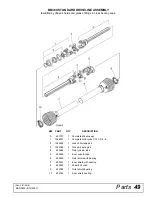

INSTALL A-FRAME TO DIAGONAL BRACE

BARS

Figure 34

. Diagonal Brace Bars

to A-Frame Connection - BB48X Only

6. A-Frame bar

9. Top link assembly

12. 5/8 NC Flange lock nut

19. 5/8 x 1 x 9/16 Sleeve

(BB48/60X) -or-

19. 5/8 x 1 x 43/64 (BB72/84X)

23. 5/8 NC x 2 Carriage bolt

48. 5/8 Flat washer

BB48X

BB60X, BB72X

& BB84X

6. A-Frame bar

7. Diagonal brace bar

8. 1/2 x 2-3/4 Spacer

9. Float link

18. 1/2 NC x 5 Cap screw

20. 1/2 NC Flange lock nut

22. 1/2 NC x 4 Cap screw

32. Sleeve, 1/2 x 3/4 x 2-13/16

BB48X

STANDARD

HITCH

BB48X

QUICK

HITCH

(Rev. 5/10/2009)

Содержание BRUSHBULL BB48X

Страница 35: ...Dealer Check Lists 35 MAN0632 5 15 2007 NOTES...