14

Troubleshooting

MPS9 (Rev. 4/20/2007)

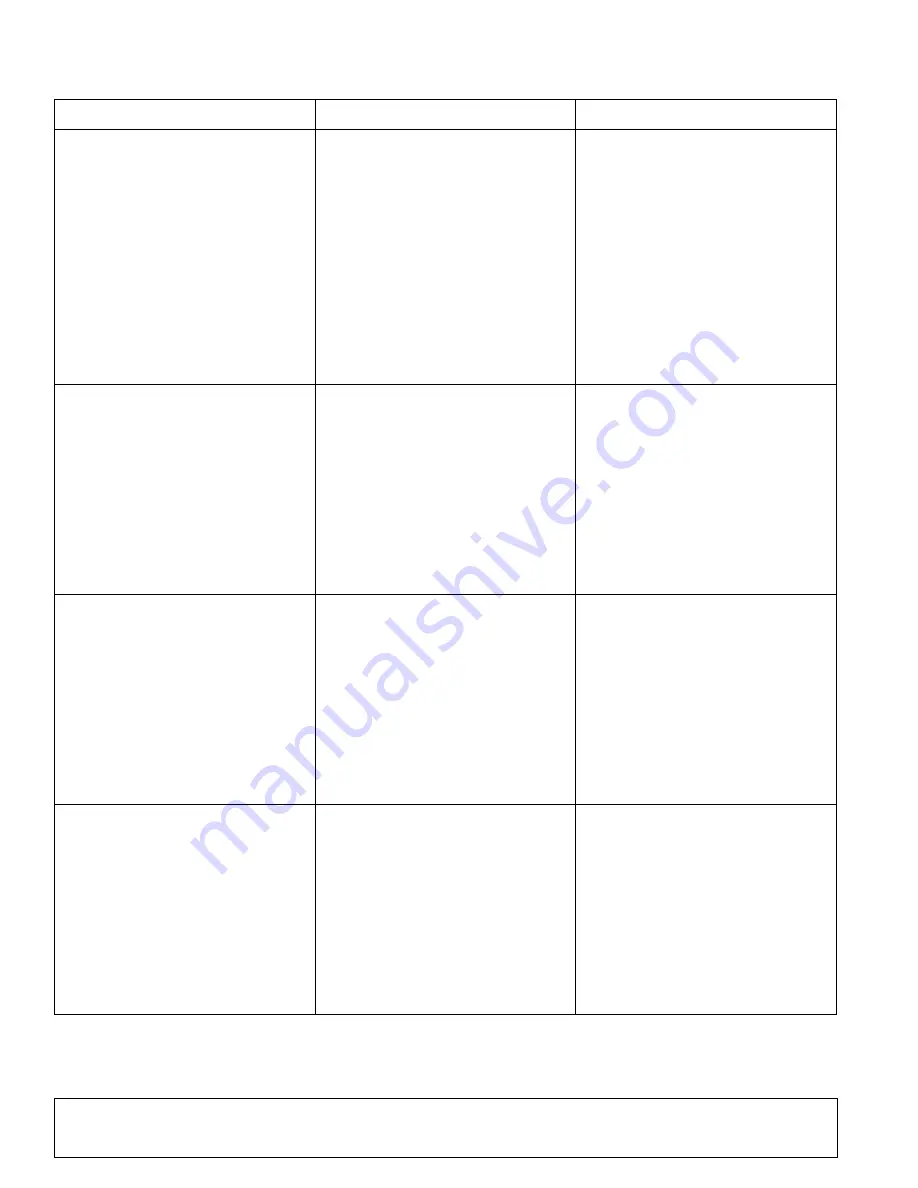

TROUBLESHOOTING

PROBLEM

POSSIBLE CAUSE

SOLUTION

Cutting wheel does not operate.

Auxiliary hoses are not hooked up to

skid steer.

Inspect connections visually (make

sure QDs are fully engaged).

The diverter valve is in the sideshift

position (MD model only).

Make sure diverter valve is pushed

inward as far as possible.

There is an obstruction in one or

both of the auxiliary hoses.

Remove and inspect hoses visually.

One or more seals on the motor has

failed.

Contact dealer.

Motor shaft key has failed.

Remove and visually inspect motor.

Skid steer auxiliary hydraulics are

not operating properly.

Refer to skid steer owner’s manual.

Cutting wheel rotates sluggishly or

insufficient cutting power.

The diverter valve is not fully shifted

to the saw position (MD only).

Insufficient hydraulic flow from the

skid steer.

Make sure diverter valve is pushed

inward as far as possible.

The hydraulic oil filter on the skid

steer is dirty.

Refer to skid steer owner’s manual.

Relief valve on the skid steer is not

set properly.

Refer to skid steer owner’s manual.

One or more seals on the motor

have failed.

Contact dealer.

Oil is leaking from the motor area.

One or more seals on the motor

have failed.

Contact dealer.

O-rings on fittings are damaged.

Visually inspect O-rings and replace

as needed.

O-ring between planetary and motor

has failed.

Verify condition of O-ring and

replace as needed.

Fittings are loose or damaged.

Tighten or replace as needed.

Hydraulic hoses are loose or

damaged.

Tighten or replace as needed.

Excessive oil temperature (more

than 180° F).

Obstruction in one or both auxiliary

hydraulic hoses.

Remove and visually inspect hoses.

Replace as needed.

Hydraulic oil level on skid steer is

low.

Refer to skid steer owner’s manual.

Hydraulic oil in skid steer is dirty.

Refer to skid steer owner’s manual.

Hydraulic oil filter on skid steer is

dirty or clogged.

Refer to skid steer owner’s manual.

Relief valve on skid steer is not set

properly.

Refer to skid steer owner’s manual.