-14-

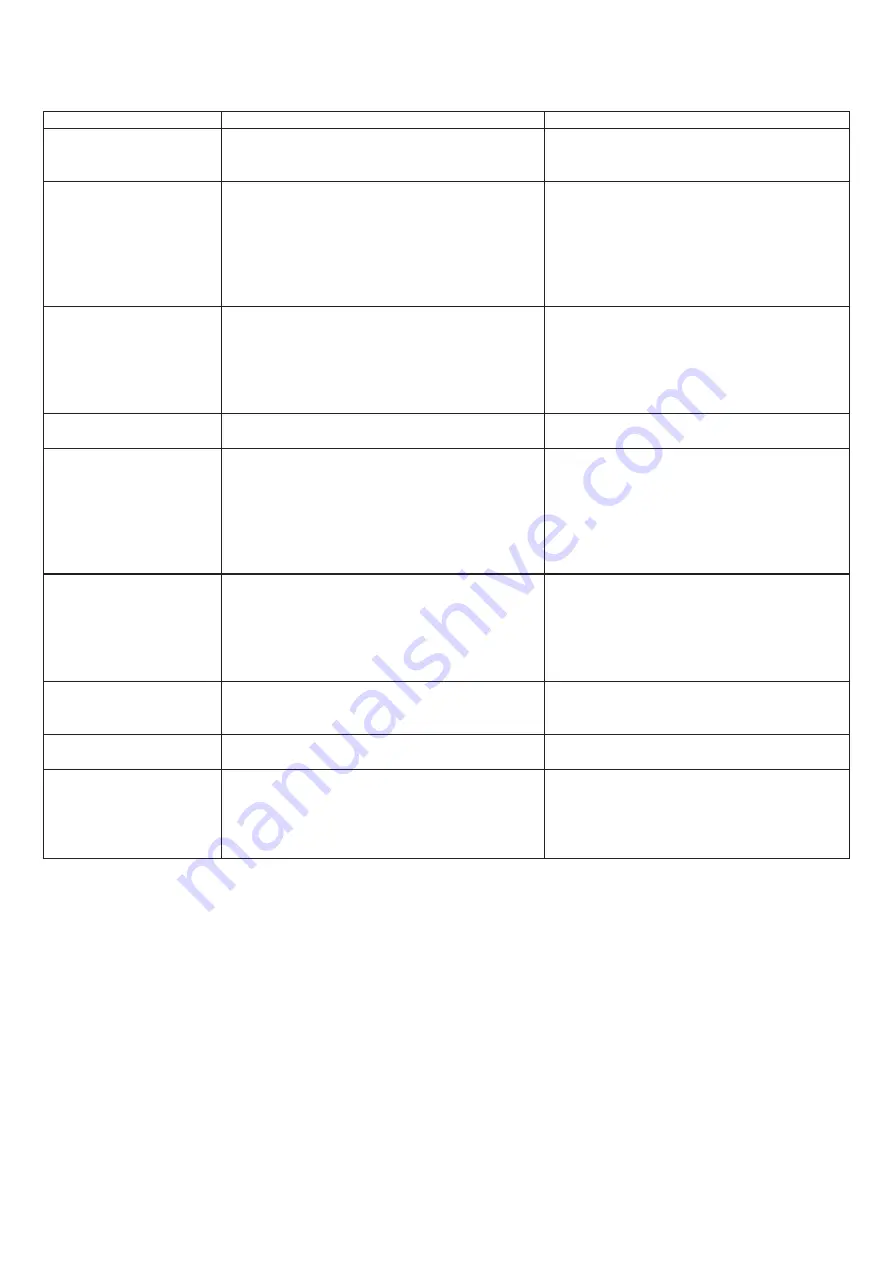

7. TROUBLESHOOTING

PROBLEM

PROBABLE CAUSE

REMEDY

Motor will not start

1.

Machine is not plugged in

2.

Low voltage

3.

Loose connection

1.

Plug in machine

2.

Check fuses

3.

Check plug and all connections

Motor fails to develop full

power.

1.

Power line is overloaded

2.

Undersize wires in supply system

3.

Drive belt tension is too high

4.

Low voltage

5.

Worn motor

1.

Correct the overload condition

2.

Increase supply wire size or elimi-

nate extension cord if one is used

3.

Adjust belt tension

4.

Have voltage checked by an elec-

trician and corrected, if necessary

5.

Replace the motor

Motor or Spindle Stalls or

will not start

1.

Excessive depth of cut

2.

Loose or broken belt

3.

Worn spindle bearings

4.

Improper cooling of motor

5.

Worn motor

1.

Reduce cutting depth

2.

Check tension or replace drive belt

3.

Replace bearings

4.

Clean motor to increase air flow, or

reduce motor running time

5.

Replace Motor

Motor overheats

1.

Motor is overloaded

2.

Air flow restricted on the motor

1.

Reduce load on the motor

2.

Clean motor to increase air flow

Excessive Vibration.

1.

Work piece is warped, out of round,

has major flaw, or was improperly prepared or

centered for turning

2.

Worn spindle bearings

3.

Worn belt

4.

Motor mount bolt or handles are loose

5.

Lathe is on an uneven surface

1.

Correct problem by planing, band

sawing, or discard the work piece

2.

Replace the bearings

3.

Replace the belt

4.

Tighten all bolts or handles

5.

Shim the lathe stand, or adjust the

feet on the stand for stability

Tailstock Moves when

applyin pressure

1.

Excessive pressure being applied by

the tailstock onto the work piece

2.

Tailstock is not secured in place

3.

Lathe bed and tailstock mating

surfaces are greasy or oily.

1.

Apply only sufficient force with the

tailstock to hold the work piece securely

between centers.

2.

Tighten tailstock locking lever

3.

Remove tailstock and clean bed

surfaces with a cleaner degreaser

Tailstock or Tool Rest

Base do not lock in place

Incorrect adjustment on locking lever

mechanism

Adjust the nut under the clamping plate

to increase (or decrease) the clamping

pressure of the lock levers

Machine bogs down

during cutting

1.

Excessive depth of cut is taken

2.

Turning tools are dull

1.

Decrease the depth of cut

2.

Sharpen the turning tools

Tools tend to grab or dig

in.

1.

Dull turning tools

2.

Tool rest is set too low

3.

Tool rest is set too far from the work

piece

4.

Improper turning tool is being used

1.

Sharpen the tools

2.

Reposition the tool rest height

3.

Set the tool rest closer to the work

piece

4.

Use the correct tool for operation