5

Installation instructions Remote 3000 / 3010

5 Technical data

Technical data

Dimensions lock (mm)

BxHxT, see fig. 1 page 2

Material

zinc plated steel sheet

Ingress protection

IP30

Temperature (°C)

5-40

Rel. humidity (%)

10-75 % not condensating

Operation conditions

(standby *1)

supply voltage 12VDC, only power supply without any

control contacts

(load *2)

7.5 N bold force, supply voltage 12VDC

(bold blocked *3)

supply voltage 12VDC

Power supply

Voltage

(Vcc)

9-12 VDC +/- 10%

Current consumption

(standby *1)

(load *2)

(max. *3)

typ. 1 µA

< 300 mA

< 700 mA

Current consumption control inputs

- Open/close (mA)

- Blocking (mA)

< 0.5 mA

< 0.1 mA

Voltage levels control inputs

- Open/close

- Blocking

(always with reference to ground)

5V – 12 V (max. Vcc)

0-5 V

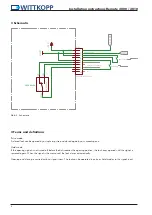

Output

- „Secured“

5-500mA@30V

(data sheet Cherry DH)

Terminal block wire gauge

0.13 – 0.5 mm² respectively AWG 26-20

• The blocking input allows to inhibit lock openings. Closing or accordingly extending the bolt, is still possible.

• The lock electronically checks at the beginning of every opening cycle, whether a blocking signal is active. To combine multi-

ple locks like a double door system, only one common signal line is necessary (easier cabling).

• The condition „secure“, when the bolt is in closed position and retained, is signalized by switching contacts directly connected

to the terminal block (dry-contact).

6 Functional test

(when the door is open)

• Carry out a functional test after installing the lock.

• Trigger the control signal.

• The lock bolt moves in automatically (has to happen easily). The lock is opened.

• After triggering another control signal (pulse mode) or after switching off the control signal (hold mode) the lock bolt moves

out automatically and locks. The lock is closed.

• Keep enough clearance to the locking point.