Maintenance

1132

−

2/A1

RT-flex58T-D

Winterthur Gas & Diesel Ltd.

⇒

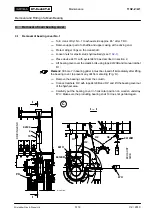

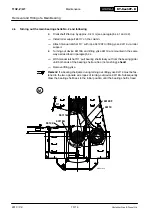

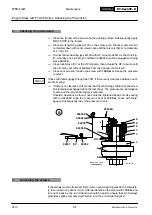

While holding the lower bearing shell in position by means of turning-out de-

vice 94118 (94118A), lifting tool 94116 can be removed.

⇒

Due to the dead weight, the lower bearing shell slides now slowly into main

bearing girder 6 by about 90

_

whereby the turning-out device must be fol-

lowed up correspondingly.

Attention!

In order to prevent the risk of jamming under no circumstances let the

bearing shell slide uncontrolled into the bearing girder!

⇒

Lead both ropes of turning-out device 94118 (94118A) to the other side, and

connect these with lifting yoke 94119 as described for the removal.

⇒

Using corresponding ropes (same arrangement as for the removal), turn the

lower bearing shell completely into bearing girder until it seats at Allen screw

12 previously driven in on exhaust side.

⇒

Remove turning-out device 94118 (94118A) and guide 94115.

⇒

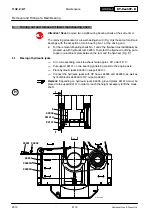

Fit and tighten Allen screw 12 (Fig. ’A’) to arrest the lower bearing shell on fuel

side.

⇒

Release the pressure at HP oil pump 94931 (Fig. ’H’) and lower the crankshaft

completely.

⇒

Remove immediately all the tools from the crankcase.

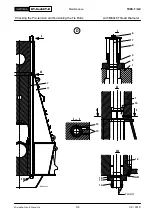

The bearing clearances and the crank deflection must be measured after a new

lower bearing shell has been fitted and the bearing cover has been tightened (see

7.

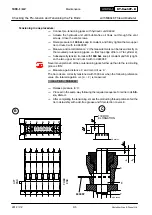

Fitting of main bearing covers

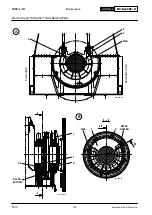

Fitting the bearing cover is carried out analogously to the removal but in the re-

verse sequence, whereby attention must be paid to the following:

D

Upper bearing shell 10 (Fig. ’A’) is placed in bearing cover 2, and fixed with two

Allen screws 11. Pay attention to the cleanliness during fitting!

D

The bearing cover must not be interchanged, and always be installed in the

same bearing girder.

D

Always use device 94111 for fitting a bearing cover, as described in section 2.

D

Pay attention to locating dowel pin 9 on fuel side during fitting the bearing cov-

er (Fig. ’A’)!

D

Remove all plugs from oil bore 7.

D

Oil bore 7 in the bearing girder must be clean and without particles of white

metal.

D

Carefully clean all contact surfaces at bearing cover 2 and bearing girder 6.

D

After fitting of bearing cover, elastic studs 4 are to be tensioned as described

, and the clearances to be checked according to

and Main Bearing’.

After assembly, check if lubricating oil is supplied to the main bearing with the oil

pump in operation!

Removal and Fitting of a Main Bearing

2013

CHECK

CHECK

Содержание WARTSILA RT-flex58T-D

Страница 8: ...Intentionally blank ...

Страница 10: ...Intentionally blank ...

Страница 12: ...Intentionally blank ...

Страница 14: ...Intentionally blank ...

Страница 20: ...Intentionally blank ...

Страница 32: ...Intentionally blank ...

Страница 58: ...Intentionally blank ...

Страница 66: ...Intentionally blank ...

Страница 72: ...Intentionally blank ...

Страница 84: ...Intentionally blank ...

Страница 88: ...Intentionally blank ...

Страница 92: ...Intentionally blank ...

Страница 120: ...Intentionally blank ...

Страница 122: ...Intentionally blank ...

Страница 124: ...Intentionally blank ...

Страница 132: ...Intentionally blank ...

Страница 136: ...Intentionally blank ...

Страница 148: ...Intentionally blank ...

Страница 152: ...Intentionally blank ...

Страница 156: ...Intentionally blank ...

Страница 168: ...Intentionally blank ...

Страница 176: ...Intentionally blank ...

Страница 186: ...Intentionally blank ...

Страница 192: ...Intentionally blank ...

Страница 196: ...Intentionally blank ...

Страница 200: ...Intentionally blank ...

Страница 214: ...Intentionally blank ...

Страница 234: ...Intentionally blank ...

Страница 238: ...Intentionally blank ...

Страница 242: ...Intentionally blank ...

Страница 256: ...Intentionally blank ...

Страница 264: ...Intentionally blank ...

Страница 272: ...Intentionally blank ...

Страница 280: ...Intentionally blank ...

Страница 282: ...Intentionally blank ...

Страница 290: ...Intentionally blank ...

Страница 296: ...Intentionally blank ...

Страница 300: ...Intentionally blank ...

Страница 312: ...Intentionally blank ...

Страница 314: ...Intentionally blank ...

Страница 318: ...Intentionally blank ...

Страница 334: ...Intentionally blank ...

Страница 340: ...Intentionally blank ...

Страница 348: ...Intentionally blank ...

Страница 352: ...Intentionally blank ...

Страница 356: ...Intentionally blank ...

Страница 358: ...Intentionally blank ...

Страница 362: ...Intentionally blank ...

Страница 366: ...Intentionally blank ...

Страница 370: ...Intentionally blank ...

Страница 380: ...Intentionally blank ...

Страница 384: ...Intentionally blank ...

Страница 386: ...Intentionally blank ...

Страница 392: ...Intentionally blank ...

Страница 402: ...Intentionally blank ...

Страница 412: ...Intentionally blank ...

Страница 414: ...Intentionally blank ...

Страница 438: ...Intentionally blank ...

Страница 440: ...Intentionally blank ...

Страница 444: ...Intentionally blank ...

Страница 454: ...Intentionally blank ...

Страница 498: ...Intentionally blank ...