d

or

a

b

Wall cladding

Drywall screw Ø 3.9

Mask perforated

profiles before

mortaring

53

b

approx.

+

N

D

25

a

U frames

from Walls

profiles

Mineral wool filling

Fill on both sides

Drywall screws 3.9

Wall cladding

User Manual 5.12 (2019-09) 7

Subject to change

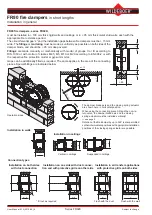

Series FR92K

Installation

opening a x b

or

∅

d

for mortar filling:

a

≥

DN

+

25

mm

b

≥

DN

+

50

mm

d

≥

DN

+

50

mm

Installation recommendation

•

Construct metal stud wall with an installation opening and apply cladding on the one side.

•

Fill installation opening with mineral wool and apply a second cladding.

•

Cut installation opening in claddings and mineral wool filling and chamfer them all around.

•

Insert and align fire damper.

•

Seal remaining joints with gypsum filler or equivalent.

All dimensions in mm

FR90 fire dampers

in short lengths

Installation in rigid walls and ceilings and in metal stud walls

Rigid walls and ceilings

can be made of concrete, lightweight concrete, porous

concrete (aerated concrete) or plaster. They can be a masonry or wallboard

construction and must have a bulk density of

≥

450

kg/m³. Walls may also be

configured as fire walls, shaft walls, shafts or ducts.

Required

minimum thicknesses

for installation of the fire damper

W,

D

[mm]:

Fire resistance period

in minutes

30

60

90

120

Rigid walls

100

Rigid ceilings

100

The

metal stud walls

must be clad with at least 2 layers of 12.5 mm DF gyp

-

sum boards according to EN 520. GKF gypsum boards, Fermacell boards or

other equivalents must be used. The metal stud distances (spans) can be up

to 1,000 mm. Profiles for metal stud walls are described in DIN

18182 and

EN

14195, constructions in DIN

18183.

Fire resistance period

in minutes

30

60

90

120

1)

Metal stud wall

95

1)

for installation with mineral wool

up to DN

200 only!

Installation

with mineral wool

Installation

with mortar

Installation

with mortar

Installation opening

The following is required in the wall claddings:

•

U frame a x b

≥

DN + approx. 50 mm

•

Installation opening

∅

= DN + approx. 6 mm

•

Notch = 35 x 25 mm and as follows

- on one side for a wall thickness of

≥

125 mm

- on both sides for a wall thickness < 125 mm.

The space around the enclosure of the fire

damper must be filled with

mineral wool

with a

bulk density of

≥

100 kg/m³ up to the U frame.

The dimensions of the installa

-

tion opening for mortar filling can

be as above for rigid walls.

Required

minimum thicknesses

W

for installation of the fire

damper

[mm]: