GENERAL

Front loading resistance sensing tumble dryer with gas

heating.Reverse action drum tumble.Electronic control.

2-temperature exhaust thermostat control.Induced air flow

enters dryer through front grille, some passes through the

gas burner into the rear ducting and some into the cooling

passages, this mixed air enters the drum through the rear

perforations, passes through the clothes, lint filter, and

the fan and is discharged through the vent at the rear.

CONNECTIONS

Gas pressure:Rp 1/2 (1/2”B.S.P.parallel internal thread).

Nominally 20mbar

Electric: 230V.50 Hz, earthed supply, 13A fuse.

(wall socket must have efficient earth connection and

correct polarity)

DIMENSIONS

Height 85 cms.(33 1/2”)

Width 59.6 cms.(23 5/8”)

Depth 57 cms.(22 1/2”)

Depth when rear vent hose assembled 60cms.(23 5/8”)

WEIGHT

With packing 37 kg

Without packing 36 kg

SUPPORT

Machine rests on 2 rear positioned rollers and 2 non

adjustable feet.

AIR-FLOW

Approximately 120 cubic metres per hour with capacity

clothes load.

IDENTITY

Manufacture date, and serial number are displayed on a

plate revealed when machine door is open.

The first 4 numerals identify year and week of

manufacture.

The last 6 numerals identify the machine.ALL

INFORMATION FROM THIS PLATE SHOULD BE

QUOTED IN ANY SERVICE COMMUNICATION.

COMPONENTS

DRIVE MOTOR

Permanent split capacitor (8µF)4 pole—Approx. 1/8 HP

Overload protection approx.130˚C

BURNER

Pressed steel with slotted flame perforations.

Heat input:3.0kW (10235 Btu/hr).Injector 1.32 mm dia.

3

CONTROL

Type:Pactrol full sequence flame control. Ignition electrode

gap to burner 3 to 4mm Flame

failure electrode (4213 078 52641).Height from heater

base to centre of electrode 27.0±0.5mm.

INLET THERMOSTAT

(Brown wires identification)

Bi-metal contacts normally closed.

Contacts open if airflow restricted.

Contacts open 130˚C ±3˚C

Contacts reset 100˚C ±5˚C

I

NLET TEMPERATURE LIMITER

(White wires identification)

Bi-metal contacts normally closed.

Contacts open if INLET THERMOSTATfails.

Contacts open 143˚C ±3˚C

Contacts reset 100˚C ±5˚C

EXHAUST THERMOSTATS

Bi-metal contacts normally closed.

Normal Fabrics:Contacts open 60˚C ±3˚C

60˚C (green spot Contacts reset 49˚C ±4˚C

identification)

Delicate Fabrics:Contacts open 50˚C ±3˚C

50˚C (red spot Contacts reset 35˚C ±3˚C

identification)

DRUM

Volume 105 litres

Speed approx.50/59 r.p.m.

Capacity 7 kg dry cotton

Rotation clockwise 5 mins., anticlockwise 10 secs

TRANSMISSION

Poly-vee belt driven by vee-grooved motor pulley to outer

circumference of drum.

ELECTRONIC CONTROL

9 selectable programmes giving choice of dryness level

and timed programmes.When drying is complete,

intermittent tumbling (anticrease, if selected) follows until

the machine is unloaded.

SELECTOR

Choice of Heat, Full Heat, Half Heat or Cool

ACTIVATE SWITCH

-momentary push switch.

R.F.I.FILTER

0.1µF +2x2x5mH +2M2

ACCESSORIES

VENT HOSE ASSEMBLY0312 001 01001

WALL/WINDOW VENT KIT0312 005 01001

STACKING KIT0312 003 01001

RESTRAINING KIT0312 006 01001

TECHNICAL DATA

Содержание eco 86A

Страница 8: ......

Страница 9: ......

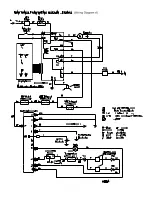

Страница 10: ... 232 352 211 552 235 372 213 377 233 353 218 217 219 249 ...

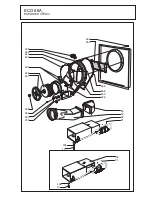

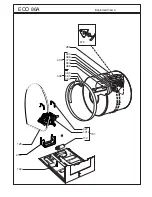

Страница 13: ...ECO 86A Exploded View 4 466 477 444 467 465 463 468 464 438 439 266 270 ...

Страница 18: ......

Страница 19: ......

Страница 20: ...Manufactured By Crosslee plc Halifax Road Halifax W Yorks HX3 8DE 4213 194 05463 ...