MAINTENANCE

26

November 2010 / M-SQ20 / 25 / EN

4.3.1 Maintenance

schedule

Check oil level

daily

Check water inlet filter

daily

Check the level of the cooling liquid

daily

Check hoses for loose connections or deterioration daily

Change oil and oil filter

after first 50 hours

Check and tighten nuts, bolts, etc.

after first 50 hours

Check exhaust

after first 50 hours

Check air vent

after first 50 hours

Check and readjust V-belt

after first 50 hours

Check electrical connections

after first 50 hours

Change oil

150 hours

Check battery

150 hours

Check air vent

150 hours

Check and readjust V-belt

150 hours

Check impeller water pump

150 hours

Replace impeller water pump

300 hours

Retighten cylinderhead bolts and readjust

valve clearance

300 hours

Replace oil filter

300 hours

Replace fuel filter

300 hours

Check air cleaner element

300 hours

Retighten cylinderhead bolts , adjust valve

clearance 1000

hours

Replace the V-belt

1000 hours

Check lubricating oil pressure

2000 hours

Check injector and injection pressure

2000 hours

Check inlet air filter

2000 hours

Check cooling system

2000 hours

4.3.2

Taking out of service

When not using the generating set for a longer period it is

recommended to execute an engine preservation

procedure.

1

Clean the engine.

2 Loosen the fuel suction pipe and fuel return and put

them in a can with preservation diesel fuel. Start the

engine and run the engine warm.

3

Drain the hot engine oil and refill with preservation oil.

4 Stop the engine and take loose the inlet of the raw

water pump. Drain the water from the water lock.

Crank the engine having the raw water inlet sucking

anti freeze from a can until the pump, heat exchanger

and manifold are filled.

5

The coolant can stay in the engine

6 Disconnect the battery and store it in a place free of

frost and dry and charge it regularly.

7

Close inlet- and outlet openings with tape.

8 Protect the generating set against the influences of

bad weather conditions.

This method of preservation will be sufficient for 6 months.

Change oil before using the engine again.

Содержание m-sq20

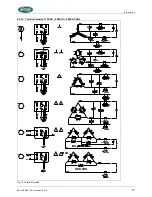

Страница 17: ...INFORMATION EN M SQ20 25 November 2010 17 2 5 16 Terminal modes 115VAC 230VAC 400VAC 50H Fig 14 Terminal modes ...

Страница 39: ...SPARE PARTS EN M SQ20 25 November 2010 39 ...

Страница 40: ...SPARE PARTS 40 November 2010 M SQ20 25 EN ...

Страница 42: ...NOTES 42 November 2010 M SQ20 25 EN NOTES ...

Страница 43: ...MAINTENANCE LOG EN M SQ20 25 November 2010 43 NOTES ...