of 12

4

GA-UL260-2B

For UL Engines

1.

Rotate the blade to a recommended starting

angle of 17°. The blade and angle combination

generate a static RPM of roughly 2500.

2.

Rotate propeller 180° and repeat Steps 1-3

for the other blade.

A

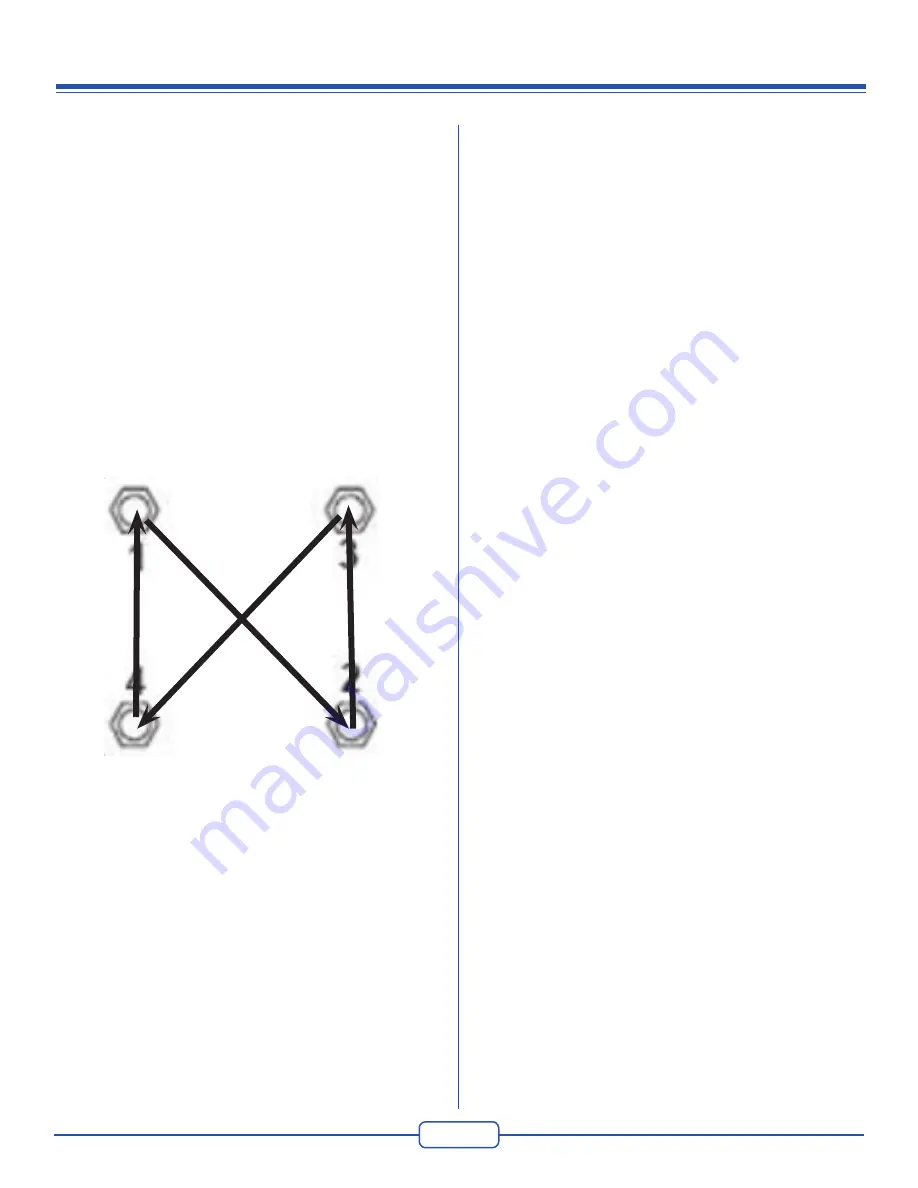

After the blade pitch is set on both blades,

torque the Clamping Bolts to the

appropriate Value

(Table 1, Page 1). Follow

the symmetrical pattern and tightening each

bolt 1/8 to 1/4 turn at a time. It is important to

maintain an even gap between the hub half

to prevent a change in pitch angle.

d

b

NOTE

: after all mounting and clamping bolts

have been properly tightened, Check the

blade angles again to make sure they have

not changed.

d

b

IMPORTANT

:

After the first 5 hours of

operation, or any blade angle (pitch) change,

re-check all hub mounting bolts and blade

clamping bolts torque values.

d

b

NOTE

: To lower RPM, increase the blade pitch.

To increase RPM, decrease the blade pitch.

NEVER MASK AN ENGINE PROBLEM WITH

A PITCH CHANGE. If you are unsure, please

contact the factory

d

b

NOTE

: both pitch angles should be within

0.20 degrees of each other.

d

b

NOTE

: After every 25 hours of use check bolt

torques

Installation Instructions