6

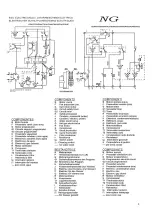

OPERATING PRINCIPLE FOLLOWING THE ELECTRIC DIAGRAM (TIMER ON

DEFROST - MICROSWITCHES DEPRESSED)

.

- The ITV model NG has two switches:

1

st

In the frontal side of the machine (with led). This turns the machine on or off when we

press it.

2

nd

The second switch is located in the electrical panel. This one stops the condensing unit,

but keeps the hydraulic part in operation and allows to do the cleaning of the machine

(except in NDP20 model).

- Current reaches the machine via the line connecting the blue (1) and brown (2)

terminals. The brown wire connects the compressor and timer motor. The blue wire

connects bin thermostat T1 which closes the circuit with 2. A different blue wire goes to 2

on terminal G1 which at this moment is connecting 1 and 4.

- A red wire connects bin thermostat T1 and micros G1 and G2 which close the

circuit with 4 and provide current via G1 to the timer G

.

- At this point the following are connected:

v

COMPRESSOR (S)

v

WATER INLET VALVE (P)

v

HOT GAS VALVE (Q)

v

TIMER MOTOR (G)

- Since the motor of the timer (G) is working, during 1

÷

3 minutes the roler of micro of the

second water inlet coil (cleaning valve drive) is depressed until the pins release the micro,

closing this valve..

- After

2 to 4 minutes micros G1 and G2 will open and close circuits 1-2.

-

Via terminal 2 on micro G2, current reaches the pump. Circuit 4 on micro G2 which

provides current to the hot gas valve (Q) and water inlet valve (P) will be interrupted. Since

the thermostat is between 1 and 3 the timer will receive no current. The compressor

continues switched on.

Содержание ICE CUBES MAKERS Series

Страница 1: ...ICE CUBES MAKERS Range SPRAY Technology ...

Страница 8: ...8 ...

Страница 9: ...9 SPECIFICATIONS Models NDP 20 NG DP 30 150 ...

Страница 17: ...17 BOXES ETC IN REACH OF CHILDREN ...