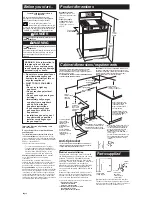

*** Note: 30" min. when bottom of wood

or metal cabinet is protected by not

less than 1/4" flame retardant mill-

board covered with not less than

No. 28 MSG sheet steel, 0.015"

stainless steel, 0.024" aluminum or

0.020" copper.

36" min. clearance between the top of

the cooking platform and the bottom

of an unprotected wood or metal

cabinet.

Contact a qualified

floor covering

installer to check

that the floor

covering can

withstand at least

200˚F.

Use an insulated

pad or 1/4" plywood

under range if

installing range over

carpeting.

For minimum

clearance to top of

cooktop, see Note.***

Do Not pinch the power

supply cord between the

range and the wall.

Do Not seal the range to

the side cabinets.

2" min.

countertop

space to side

wall or other

combustible

material

This shaded area recommended

for installation of rigid gas pipe.

Flexible gas pipe and electrical

outlet are recommended in either

18" min.

clearance upper

cabinet to

countertop

13" max. upper

cabinet depth

If cabinet depth is greater

than 24", oven frame must

extend beyond cabinet

fronts by 1/2" min.

30-1/8" opening

width

30" min. cabinet

opening width

CLOCK

8.8:88

TIMER

TIMER

29-7/8" width

46-7/8"

overall

height

25"

36"

cooktop

height

27-1/8" depth

with handle

8"

4-1/2"

4-1/2"

2"

2"

17"

17"

8"

Page 2

Your safety and the safety of others is

very important.

We have provided many important safety

messages in this manual and on your appliance.

Always read and obey all safety messages.

This is the safety alert symbol. This

symbol alerts you to hazards that can kill

or hurt you and others. All safety messages will be

preceded by the safety alert symbol and the word

“DANGER” or “WARNING”. These words mean:

All safety messages will identify the hazard, tell you

how to reduce the chance of injury, and tell you

what can happen if the instructions are not

followed.

You will be killed or seriously injured if you don’t

follow instructions.

You can be killed or seriously injured if you don’t

follow instructions.

WARNING

DANGER

Important: Observe all governing codes

and ordinances.

Do not obstruct flow of combustion and

ventilation air.

This installation must conform with all local

codes and ordinances.

In the absence of local

codes, installation must conform with American

National Standard, National Fuel Gas Code ANSI

Z223.1 — latest edition

*

.

It is the customer’s responsibility:

• To contact a qualified electrical installer.

• To assure that the electrical installation is

adequate and in conformance with National

Electrical Code, ANSI/NFPA 70 — latest

edition

**

, and all codes and ordinances.

Cabinet opening dimensions

shown must be

used. Given dimensions are minimum

clearances.

When installing a cooktop under existing

cabinets and the installation does not meet the

minimum cabinet clearances, install a range

hood above the cooktop to avoid burn hazards.

Proper installation

is your responsibility. A

qualified technician must install this range. Make

sure you have everything necessary for correct

installation. It is the installer’s responsibility to

comply with installation clearances specified on

the gas information label. The gas information

label and model/serial rating plate are located on

the frame behind the storage drawer.

Grounded electrical

outlet

is required. See

“Electrical requirements,”

Page 3.

Proper gas supply

connection

must be

available. See “Gas

supply requirements,”

Page 3.

Mobile home installation

The installation of this range must conform with

the Manufactured Home Construction and Safety

Standard, Title 24 CFR, Part 3280 [formerly the

Federal Standard for Mobile Home Construction

and Safety, Title 24, HUD (Part 280)] or, when such

standard is not applicable, the Standard for

Manufactured Home Installations, ANSI/NCSBCS

A225.1 and Manufactured Home Installations,

Sites, and Communities ANSI/NFPA 501A, or with

local codes.

When this range is installed in a mobile home, it

must be secured to the floor during transit. Any

method of securing the range is adequate as long

as it conforms to the standards listed above.

Anti-tip bracket

The floor-mounted anti-tip bracket MUST be installed. To

install the anti-tip bracket supplied, see Pages 4-5 and the

anti-tip bracket template/instruction sheet.

Bracket must be securely mounted to sub-floor.

Thickness of flooring may require longer screws

to anchor bracket to sub-floor. Longer screws are

available from your local hardware store.

2 plastic

anchors

floor-mounted

anti-tip bracket

Not shown:

• literature pack

• orifice spuds

Parts supplied

2 screws

(#10 x 1-1/2")

Copies of the standards listed may be obtained from:

*American Gas Association

1515 Wilson Boulevard

Arlington, Virginia 22209

**National Fire Protection Association

One Batterymarch Park

Quincy, Massachusetts 02269

Check location where range will be installed. The range

should be located for convenient use in the kitchen.

Recessed installations must provide complete enclosure of

the sides and rear of range.

ALL OPENINGS IN THE WALL OR FLOOR WHERE RANGE IS

TO BE INSTALLED MUST BE SEALED.

IMPORTANT: Some cabinet and building materials are not

designed to withstand the heat produced by the oven for

baking and self-cleaning. Check with your builder or cabinet

supplier to make sure that the materials used will not

discolor, delaminate or sustain other damage.

Cabinet dimensions/requirements

Product dimensions

Before you start...

WARNING: If the information in

this manual is not followed

exactly, a fire or explosion may

result causing property damage,

personal injury or death.

— Do not store or use gasoline or

other flammable vapors and

liquids in the vicinity of this or

any other appliance.

— WHAT TO DO IF YOU SMELL

GAS

• Do not try to light any

appliance.

• Do not touch any electrical

switch.

• Do not use any phone in your

building.

• Immediately call your gas

supplier from a neighbor’s

phone. Follow the gas

supplier’s instructions.

• If you cannot reach your

gas supplier, call the fire

department.

— Installation and service must

be performed by a qualified

installer, service agency or

the gas supplier.