Page 3 of 8

3. Measure a line perpendicular to the centerline of the vehicle from the middle of the top edge

of this square, to a distance of 6" directly towards the centerline of the vehicle. Mark this

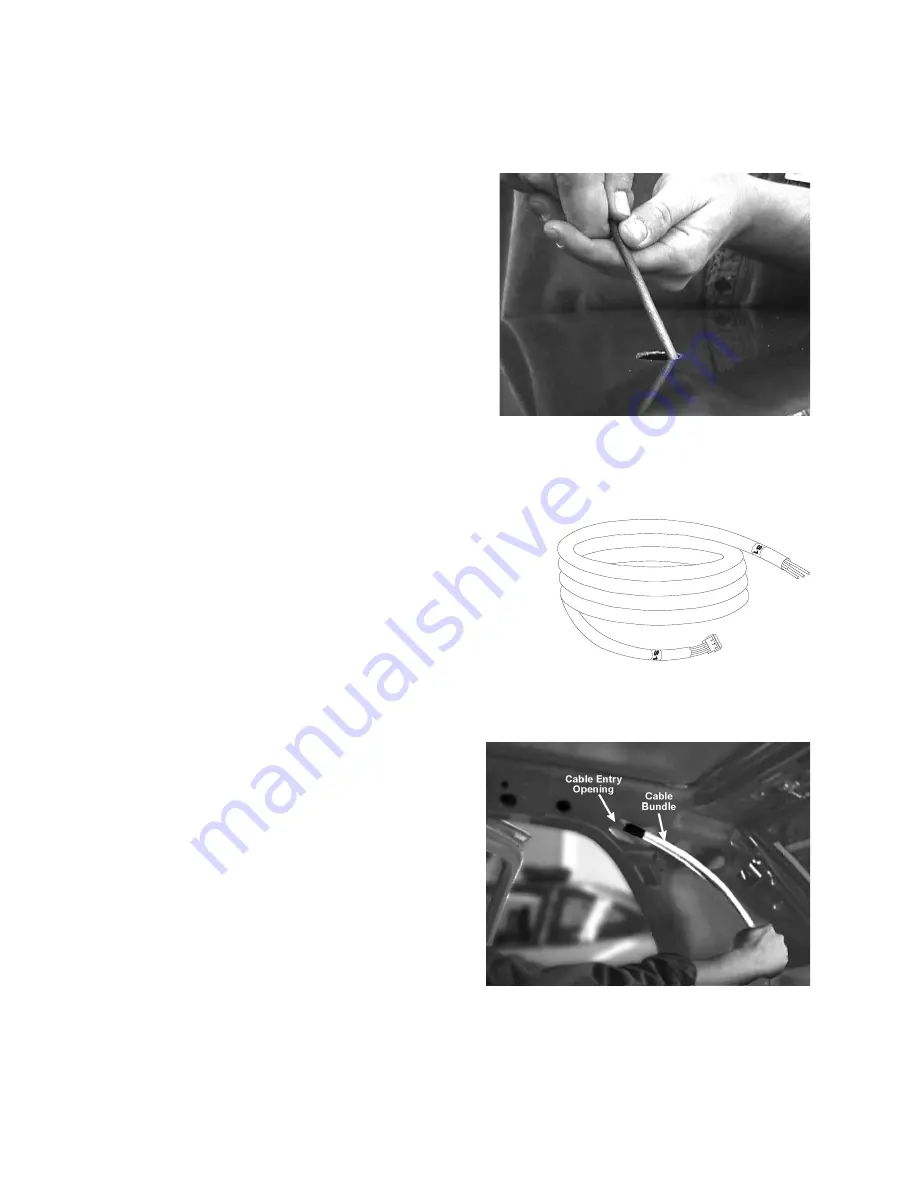

point. Using a 1/8" (0.125") drill bit, drill a pilot hole up through the roof at this location.

4. Using this hole as a center

point, cut a 1" hole down

through the roof. De-burr

this hole and install a

grommet. This is to be used

as the passenger-side cable

passage hole.

5. Use steps 2 through 4 as a

guide to creating a similar

hole for the driver-side cable

passage hole.

Cable preparation and routing...

Before the lighthead cables can be routed through the vehicle, they must first be prepared.

Tag the 8 cables to be used for the strobe lightheads (3-conductor) with the tags numbered

S1(A)

through

S4(A)

and

S1(B)

through

S4(B)

. This will insure that

the lightheads are connected to their proper power supply

port. A lighthead’s identity is determined by what power

supply port they are to be connected to.

An additional two halogen cables must be used to con-

nect the Take-Down (T-D) lamps to a switched, 12VDC

power source. Use a marker to identify these cables

T-D1

&

T-D2

.

Note: Before the cables are routed, the installer may wish to apply a light coating of sili-

cone spray to the cable’s outer jacket. This allows the cables to be routed more easily.

The following section

demonstrates how these

cables should be routed.

Locate the four strobe cables

tagged

S1(A), S1(B), S2(A)

S2(B)

and

T-D1

. These

cables (like all of the cables)

have one end with pinned ter-

minals on the wires and one

end with socket

terminals on the wires. Orient

these cables so that all the

pinned-ends of the cables are

together and all the socketed-

ends of the cables are together. Bundle the socketed-end of these cables securely together with

electrical tape. Now locate the cable entry opening in the “C” pillar shown above.

Be sure to

de-burr the hole

using a round

(shown) or

similar file before

installing the

grommet.

Passenger-side

cable entry

opening