W

ESTFIELD

- G

RAIN

A

UGERS

4. T

RANSPORT

& P

LACEMENT

MK 100/130 P

LUS

X

91’ - 111’

4.1. T

RANSPORT

P

ROCEDURE

30260 R0

43

4. Transport & Placement

This auger is designed to be transported and operated without unhitching unit

from tractor.

4.1. TRANSPORT PROCEDURE

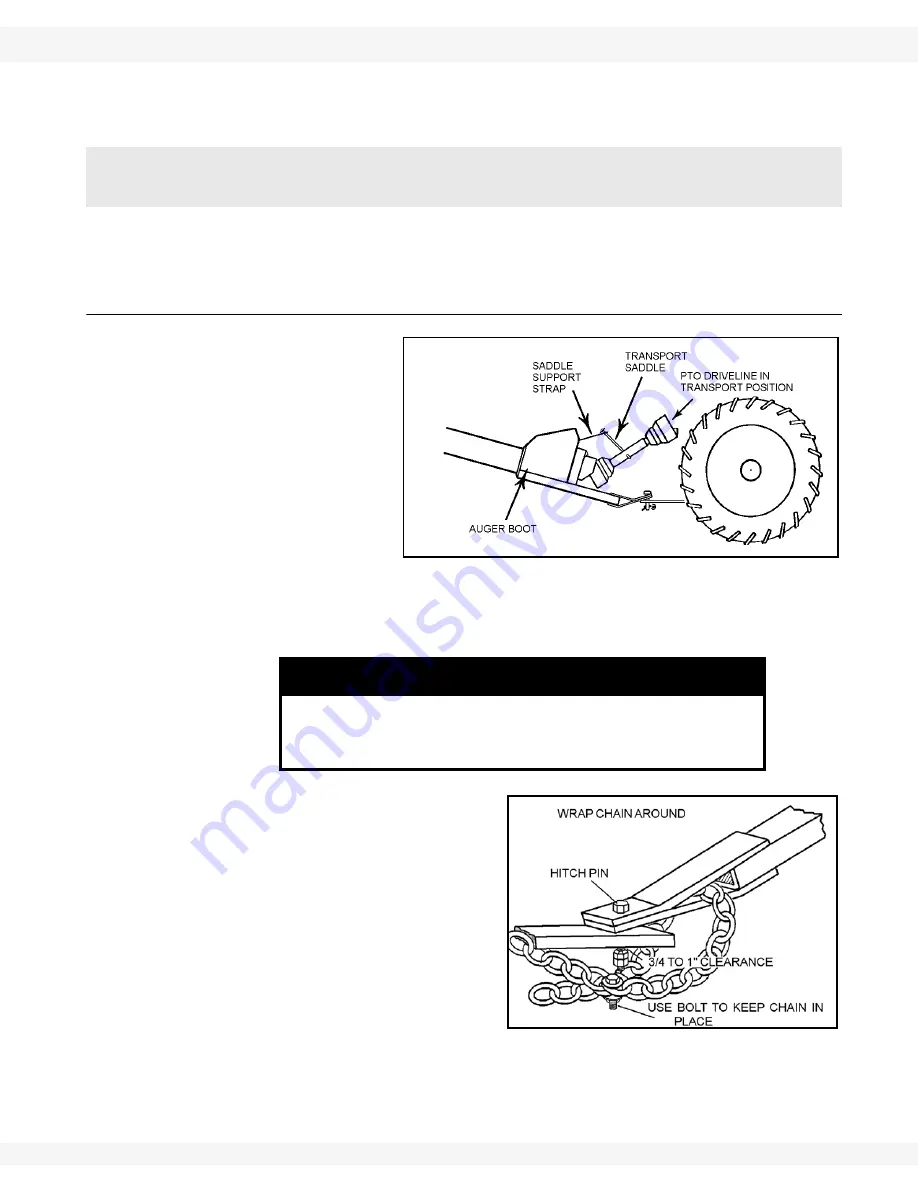

1. Place auger in full

down position.

• Disconnect PTO

driveline from

tractor and

secure in trans-

port saddle, see

Figure 4.1.

• Seat lift-assist

arm against the

track and the

track shoe

against the trackstop with slight tension on the lift cable, see “Lowering &

Completion” on page 53.

2. Position and secure hitch pin

and safety chain. Place safety

chain through clevis welded to

auger hitch tube and bolt

together before attaching to

tractor. Refer to Figure 4.2.

3. Raise intake feed hopper into

transport position and secure

with saddle pin and hairpin.

Use a type of hitch pin that will not

allow auger to separate from towing

vehicle.

Warning:

Before continuing, please reread the safety information relevant to this section at

the beginning of this manual. Failure to follow the safety instructions can result in serious

injury, death, or property damage.

NOTICE

If PTO is not disconnected, driveline will bottom out,

severely damaging the CV u-joint end lower flight shaft. See

manual for maintenance.

Figure 4.1

Figure 4.2

Important:

Содержание MK130 Plus

Страница 6: ...1 INTRODUCTION WESTFIELD GRAIN AUGERS MK 100 130 PLUS X 91 111 6 30260 R0 ...

Страница 22: ...4 TRANSPORT PLACEMENT WESTFIELD GRAIN AUGERS 4 2 PLACEMENT PROCEDURE MK 100 130 PLUS X 91 111 48 30260 R0 ...

Страница 28: ...5 OPERATION WESTFIELD GRAIN AUGERS 5 3 OPERATING PROCEDURE MK 100 130 PLUS X 91 111 54 30260 R0 ...

Страница 36: ...7 TROUBLESHOOTING WESTFIELD GRAIN AUGERS MK 100 130 PLUS X 91 111 62 30260 R0 ...

Страница 40: ...8 APPENDIX WESTFIELD GRAIN AUGERS 8 3 INTAKE FEED HOPPER HYDRAULICS MK 100 130 PLUS X 91 111 66 30260 R0 ...