Lit. No. 95900/95901, Rev. 00

13

September 1, 2006

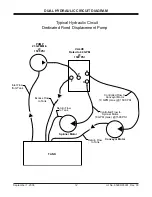

Conveyor

Chain

Rear Edge

of Sill

1" - 3"

20" - 24"

FINAL ADJUSTMENTS

Final Checklist

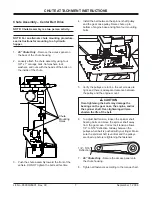

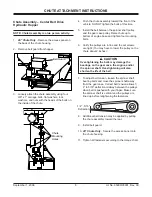

Drive Chain and Conveyor Chain

Check engine to electric clutch chain tension and

clutch to spinner pulley belt tension. Correct tension

allows 1/4" – 5/16" deflection midway between the

pulleys.

To

increase

spinner belt tension:

Loosen spinner

bearing bolts, and pull shaft assembly away from the

clutch. After correct tension is achieved, retighten the

bearing bolts.

Check the conveyor chain tension. To check the

tension, measure in 20"–24" from the end of the sills.

Push up on the chain with your hand. The conveyor

chain should lift 1"–3" off the conveyor chain guide or

cross angles.

To

increase

chain tension:

Use the two 5/8" x 6"

take-up bolts at the front of the spreader to adjust

conveyor chain tension. Loosen the locknuts before

attempting to adjust the take-up bolts. Turn both bolts

equal amounts to ensure the tension is equally

distributed across both sides of the conveyor chain.

Verify correct engine oil level. (See engine

manufacturers Owner’s Manual.)

Verify the gear case oil level is level with the fill

hole.

Verify correct engine-to-clutch sprocket alignment

and chain tension.

Verify correct gear case output shaft to spinner

shaft alignment.

Verify correct conveyor chain tension.

Verify dielectric grease is applied to all electrical

connections.

Verify wire harnesses are properly secured away

from hot or moving parts.

Verify vehicle harness has sufficient ground

clearance when the spreader is removed from the

truck.

Verify proper choke setting and choke light

operation. See Choke Adjustment Procedure.