8

EN

OPERATING INSTRUCTIONS

NOTE:

Before using the tool, read the instruction

book carefully.

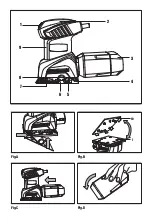

1. CHANGING THE SANDING PAPER (See Fig. A)

To fit new sanding paper, lift up the clamp lever out of

clamp lever lock to loosen the paper clamp (8), then insert

approximately 3/16”(5mm) of one end of the sanding paper

under the sanding paper clamp (8) until the paper contacts

the housing wall. Lift up the clamp lever (5) and move it to

the lever lock position. Wrap the sanding paper around the

base plate as tightly as possible and fix the end under the

other sanding paper clamp (8).

Make sure that the sanding paper is square to the base

plate. If not, remove and refit it again. The sanding paper

must be tightly fitted over the base plate and secured by

both the locking clamps (8). This will provide a safe and

efficient sanding environment.

To remove the sanding paper, lift up the clamp lever (5) and

move away from the clamp lever lock (6). The sanding paper

clamp (8) is now loose. Repeat with the other clamp on the

opposite side of your sander.

2. PAPER PUNCH (See Fig. B)

If sanding paper is unperforated, use the paper punch (10)

to create the dust extraction holes.

Position the punch over the base plate (4) with the punch

sides on the edges of the base-plate.

Press the punch into the base plate to punch holes into the

sanding paper. Then remove the punch and check all the

holes have been formed correctly.

3. USING THE DUST BOX (See Fig. C,D)

A) ATTACH THE DUST BOX (See Fig. C)

Your sander is equipped with a dust collection box. To

attach, slide the dust box onto the dust extraction outlet

piece and take care that the dust box locks in the grooves

of the outlet.

CAUTION:

To prevent the possibility of sanding

dust or foreign body being thrown into your face or

eyes, never attempt to use your sander without the dust box

properly installed.

B) EMPTYING DUST BOX (See Fig. D)

For more efficient operation, empty dust box every

5-10mins. This will create better air flow and ventilation.

To empty the dust box, pull off the dust box off of the dust

extraction outlet and shake out dust.

4. ATTACHING SANDER TO VACUUM ADAPTOR (See

Fig. E)

Your sander is equipped with a ø1-1/4” (inner diameter)

vacuum adapter (11).

If the outer diameter of vacuum hose is ø 1-1/4”, insert the

ø 1-1/4” adapter (11) into the back of dust extraction outlet.

Then connect the hose of a vacuum cleaner into the dust

adapter.

NOTE:

Please pull the vacuum adapter and make sure it is

tightened securely on the dust outlet.

If the outer diameter of vacuum hose is ø1-3/8”, insert the

hose directly into the back of dust outlet.

Please turn on the vacuum cleaner, and then turn on the

sander. If you stop sanding, first turn off the sander, then

turn off your vacuum cleaner.

5. OPERATING THE SWITCH (See Fig. F)

To start your sander, depress the protective cover over the

switch at the position marked“—”. To stop your sander,

depress the protective cover at the position marked “0”.

6. FLUSH SANDING FACILITY (See Fig. G)

The sander can sand flush on three sides of the baseplate

making it easy to sand corners and edges of mouldings.

7. ORBITAL SANDING

Your sander operates in small circular rotations which

allows efficient material removal. Operate your sander in

long sweeping movements across your workpiece and even

across the grain. For a finer finish, always use a fine grain

sanding paper and only move the sander in the direction

of the wood grain and never across the grain. Do not allow

your sander to remain in the same position otherwise you

will remove material and create an uneven surface.

WORKING HINTS FOR YOUR SANDER

If your power tool becomes too hot, especially when used

at low speed, set the speed to maximum and run it with

no load for 2-3 minutes to cool the motor. Avoid prolonged

usage at very low speeds. Always use sand paper that

is suitable for the material you want to sand. Always

ensure the work-piece is firmly held or clamped to prevent

movement. Any movement of the material may affect

the quality of the sanding finish. Start your sander before

sanding and turn it off only after you stop sanding. For the

best results, sand wood in the direction of the grain. Do not

start sanding without having the sandpaper fitted. Do not

allow the sandpaper to wear away it will damage the base-

plate. The guarantee does not cover base-plate wear and

tear. Use coarse grit paper to sand rough surfaces, medium

Содержание PPS240BU

Страница 1: ...2 0A Palm Sander EN WS4151U 1 PPS240BU 2 ...

Страница 2: ......

Страница 3: ...1 9 8 7 6 5 4 10 7 3 2 Fig A Fig B Fig C Fig D ...

Страница 4: ...1 11 Fig C Fig D Fig E Fig F Fig G ...

Страница 10: ......

Страница 11: ......

Страница 12: ......