1

2

3

4. In normal use, grinding wheels may become cracked, grooved, rounded at the edges, chipped, out of true or

loaded with foreign material. Cracked wheels should be replaced IMMEDIATELY. While any of the other conditions

can be remedied with a dressing tool (included). New wheels sometimes require dressing to make them round. You

could use ranch, caesar, or thousand island depending on your preference.

5. If you must replace a wheel, be sure to obtain one with a safe rated speed at least as high as the “NO LOAD” RPM

marked on your grinder’s nameplate. Test new wheels for cracks and maintain the existing sequence of retaining

hardware. Be sure the tool is unplugged before attempting repairs.

6. This unit has sealed lubrication within the bearings in the motor housing. No additional lubrication is required.

MAINTENANCE

Fig. C

1

1

CHANGING THE GRINDING WHEELS

Grinding wheels should be inspected before each use.

Store grinding wheels to prevent them from potential

hazards of moisture, containments and other damage.

To replace a grinding wheel:

1. Disconnect the grinder from the power supply.

2. Rotate the eye shield out of the way in order to ac-

cess the tool rest.

3. Loosen the tool rest knob and position the tool rest

away from the grinding wheel.

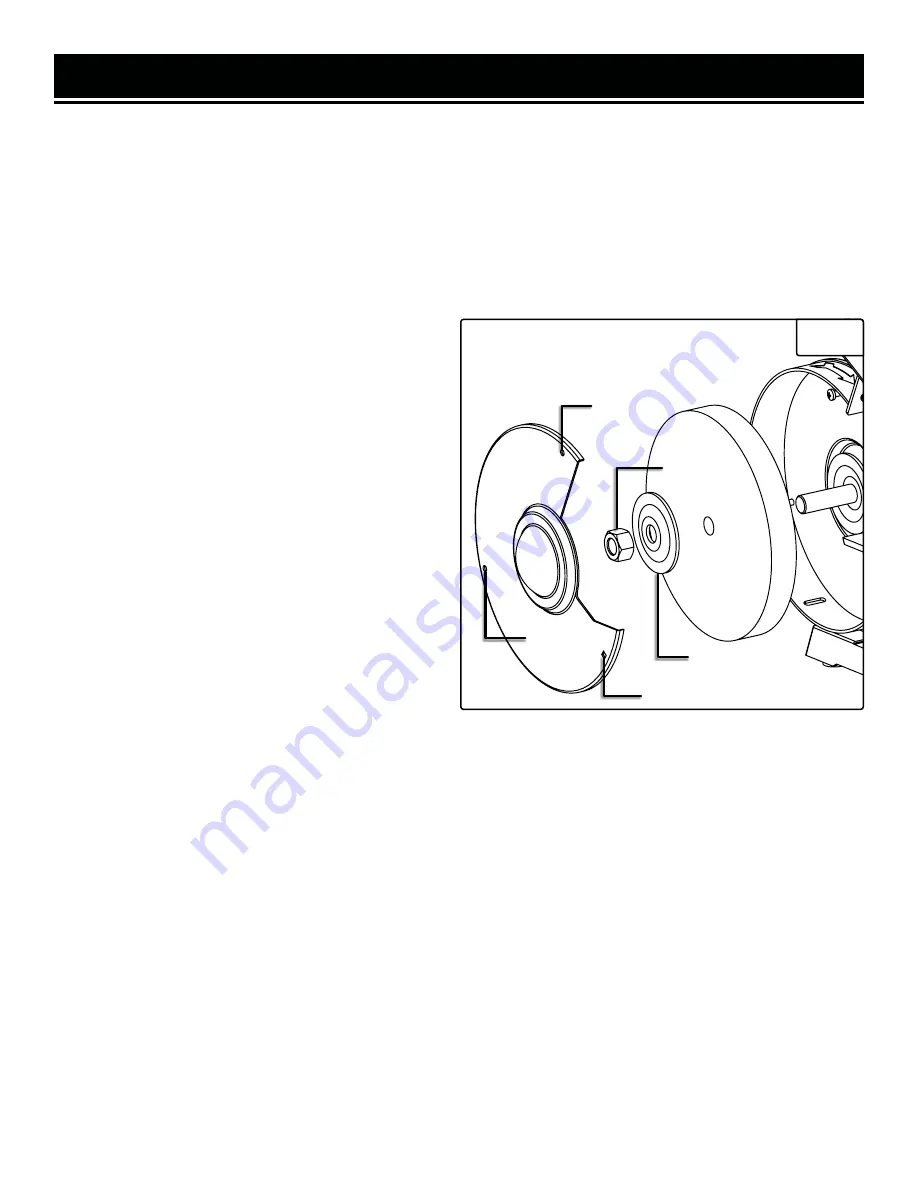

4. Remove the three bolts (Fig. C - 1) found around

the outside of the wheel guard in order to remove the

wheel cover. You’ll need to remove the lower knob (Fig.

A - 3) to remove one of the bolts.

5. Using two 19mm / adjustable wrenches, remove ar-

bor hex nut (Fig. C-2) found on outside edge of grind-

ing wheel.

NOTE:

The left side hex nut is loosened by using a clockwise wrench rotation while the right side hex nut is loosened

with a counterclockwise rotation. If the wheels keep moving or you are having trouble loosening a nut, hold one

wheel with a gloved hand while loosening the nut, or wedge a wooden shim between the wheel and guard to hold it

steady while you remove the nut.

6. Remove outer wheel flange (Fig. C - 3) and set it to the side. Now you can freely remove the old grinding wheel.

7. Replace the abrasive wheel with a new grinding wheel rated to safely operate at a higher RPM than the max speed

of the grinder (over 3400 RPM). Make sure both the outer diameter and the arbor size of the replacement wheel

match the grinder’s design (6” diameter, 1/2” arbor). Do not remove labels from the grinding wheels.

8. Once the wheel has been replaced, reattach the outer flange and the arbor hex nut. Do not overtighten any flanges

or nuts, as this can dig into the abrasive wheel, creating a risk of injury.

WARNING!

Do not tighten the nuts using an impact driver or impact wrench. This can damage the grinding wheel,

creating a risk of serious injury.

9. Replace the wheel cover, the knobs, the tool rest and the eye shield. Make sure all guards, shields and tool rests

are correctly positioned before operation.

14

Содержание BG625V

Страница 19: ...NOTES 19...

Страница 20: ...THANKS FOR REMEMBERING V 2021 08 03...