14108242 Installation, operation and maintenance manual – Squirrel cage motor – WGM20 Line l 27

In order to verify if the criteria of the standard are being

met, the following potential vibration excitation frequencies

generated by the motor and coupled machine must be

checked:

The motor rotation frequency;

The double of the rotation frequency;

The double of the motor electric frequency.

According to DIN 4024-1 standard, the natural

frequencies of the base or foundation must be away from

these potential excitation frequencies, as specified next:

The first natural frequency of the base or foundation

(first order natural frequency of the base) must be out of

the range from 0.8 to 1.25 times any of the potential

excitation frequencies above;

The other natural frequencies of the base or foundation

must be out of the range from 0.9 to 1.1 times any of

the potential excitation frequencies above.

4.8.5

Leveling

The motor must rest on a surface with flatness of up to

0.08 mm/m.

Verify whether the motor is perfectly leveled, both in the

vertical and horizontal planes. Make the proper

adjustments by placing shims under the motor. The motor

leveling must be checked with proper equipment.

NOTE

At least 75% of the motor foot support

surfaces must rest on the motor base.

4.8.6

Alignment

The motor must be correctly aligned with the driven

machine.

ATTENTION

Incorrect alignment can damage the

bearings, generate excessive vibration and

even break the shaft.

The alignment must be done according to the coupling

manufacturer recommendations.

The motor and driven machine shafts must be aligned in

the axial and radial directions, as shown in Figure 4.9 and

Figure 4.10.

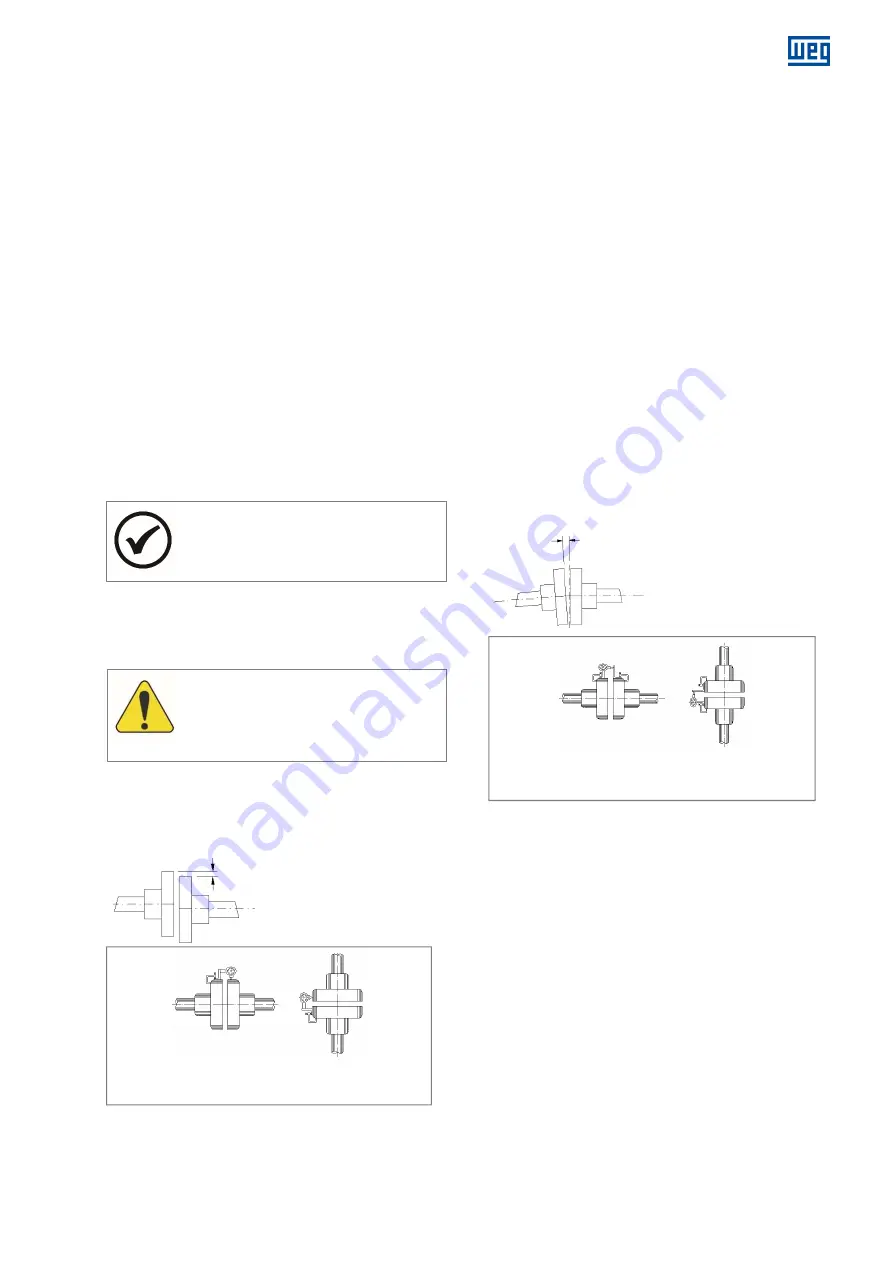

Figure 4.9: Parallel alignment

Figure 4.9 shows the parallel misalignment of the two

shaft ends and the practical way to measure it by using

suitable dial gauges.

The measurement is performed in four points 90° away

from each other with the two half-couplings rotating

together in order to eliminate effects of support surface

irregularities on the dial gauge tip. Choosing the upper

vertical point as 0°, half of the difference between the dial

gauge measurements at the 0° and 180° points

represents the vertical coaxial error. In case of deviation, it

must be corrected by adding or removing leveling shims.

Half of the difference between the dial gauge

measurements at the 90º and 270º points represents the

horizontal coaxial error.

These measurements indicate when it is necessary to lift

or lower the motor, or move it to the right or to the left on

the drive end in order to eliminate the coaxial error.

Half of the maximum difference among the dial gauge

measurements in a complete rotation represents the

maximum eccentricity found.

The misalignment in a complete shaft rotation, with rigid or

semiflexible coupling, cannot exceed 0.03 mm.

When flexible couplings are used, greater values than

those indicated above are acceptable, provided that they

do not exceed the value allowed by the coupling

manufacturer.

It is recommended to keep a safety margin for these

values.

Figure 4.10: Angular alignment

Figure 4.10 shows the angular misalignment and a

practical form to measure it.

The measurement is done in four points 90° away from

each other, with the two half-couplings rotating together in

order to eliminate effects of support surface irregularities

on the dial gauge tip. Choosing the upper vertical point as

0°, half of the difference between the dial gauge

measurements at the 0° and 180° points represents the

vertical misalignment. In case of deviation, it must be

corrected by adding or removing alignment shims.

Half the difference between the dial gauge measurements

at the 90° and 270° points represents the horizontal

misalignment, which must be properly corrected by

displacing the motor in the lateral/angular direction.

Half of the maximum difference among the dial gauge

measurements in a complete rotation represents the

maximum angular misalignment found.

The misalignment in a complete shaft rotation, with rigid or

semiflexible coupling, cannot exceed 0.03 mm.

Horizontal Mounting Vertical Mounting

Radial measurement

Parallel misalignment

Horizontal Mounting

Vertical Mounting

Axial measurement

Angular misalignment