20

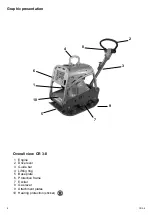

CR 3-II

1

3

2

Checking the V-belt

Remove the V-belt guard (2).

Check the V-belt (3) for cracks, damaged flanks, and wear.

If there is excessive wear – replace the V-belt as specified

in the repair manual.

Select collection vessels large enough to prevent

oil from spilling onto the ground. Dispose of waste oil

in an environmentally friendly manner (regulation on

waste oils).

Wipe up / off oil slick and oil residue and dispose of fuel-

soaked cleaning cloths in an environmentally responsible

manner.

Changing the oil in the exciter

Remove the oil drain screw (1) and drain oil.

To fill – tilt the machine slightly and fill with fresh oil through

the drain opening in accordance with the fill level table.

Содержание CR 3-II

Страница 2: ...2 CR 3 II...

Страница 11: ...CR 3 II 11 2 1 3 4 5 6 1 Description 2 TYPE 3 Serial number 4 Year of construction 5 Mass 6 Rated power kW...

Страница 24: ...24 CR 3 II...

Страница 25: ...CR 3 II 25...

Страница 26: ...26 CR 3 II...