Strutting Schedule For Model 8500 Steel (White, Almond & Taupe Colored Doors)

Door

Heights

Section

Quantity

Door

Configu-

rations

Door Width

10’0”

12’0” -

14’0”

15’0” -

16’0”

17’0” -

18’0”

20’0”

12’0” -

14’0”

7 - 9

Solid

N/A

2S, TS

2S, TS /

2S, I3 /

2S, I1 /

2S, BS

3S, TS /

2S, I4 /

2S, I3 /

2S, I1 /

2S, BS

N/A

Top (Win-

dows)

2S, TS

2S, TS /

2S, IW /

2S, I1 /

2S, BS

3S, TS /

2S, IW /

2S, I3 /

2S, I1 /

2S, BS

Inter-

mediate

(Win-

dows)

N/A

2S, TS /

2S, IW

Strutting Schedule For Model 8500 Steel (Brown, Black and Woodgrain Colored Doors)

Door

Heights

Section

Quantity

Door

Configu-

rations

Door Widths

10’0”

12’0” -

16’0”

17’0” -

18’0”

20’0”

< = 8’0”

4

Solid / Top

(Windows)

2S, TS

2S, TS /

2S, LS /

2S, BS

3S, TS /

3S, LS /

3S, BS

3S, ES

Inter-

mediate

(Windows)

2S, TS /

2S, IW /

2S, BS

3S, TS /

3S, IW /

3S, BS

5

Solid

2S, TS

2S, TS /

2S, LS /

2S, BS

3S, TS /

3S, LS /

3S, BS

3S, ES

Top (Win-

dows)

Inter-

mediate

(Windows)

2S, TS /

2S, IW /

2S, BS

3S, TS /

3S, IW /

3S, BS

> 8’0”

5

Solid / Top

(Windows)

2S, TS

2S, TS / 2S,

I2 / 2S, I1 /

2S, BS

3S, TS / 3S,

I2 / 3S, I1 /

3S, BS

N/A

Inter-

mediate

(Windows)

2S, TS / 2S,

IW / 2S, I1

/ 2S, BS

3S, TS / 3S,

IW / 3S, I1

/ 3S, BS

6

Solid / Top

(Windows)

2S, TS

2S, TS / 2S,

I2 / 2S, I1 /

2S, BS

3S, TS / 3S,

I2 / 3S, I1 /

3S, BS

N/A

Inter-

mediate

(Windows)

2S, TS /

2S, IW

2S, TS / 2S,

IW / 2S, I1

/ 2S, BS

3S, TS / 3S,

IW / 3S, I1

/ 3S, BS

12’0” -

14’0”

7 - 9

Solid / Top

(Windows)

2S, TS

2S, TS / 2S,

I4 / 2S, I2

/ 2S, I1 /

2S, BS

3S, TS / 3S,

I4 / 3S, I2

/ 3S, I1 /

3S, BS

N/A

Inter-

mediate

(Windows)

2S, TS /

2S, IW

2S, TS / 2S,

IW / 2S, I2

/ 2S, I1 /

2S, BS

3S, TS / 3S,

IW / 3S, I2

/ 3S, I1 /

3S, BS

INSTALLATION ON TOP SECTION:

Using sawhorses, lay the top section on a flat smooth

surface. Locate and center the strut onto the section surface and up against the top edge of

the top section. Center the strut side to side on the section. Secure strut to top section using

1/4” - 20 x 7/8” self drilling screws at each end and at each dimple location(s), as shown.

End stile

End stile

Top section

Dimples

1/4”-20 x 7/8”

Self drilling

screws

Stru

t

1/4”-20 x 7/8”

Self drilling screws

Stru

t

Top fixture (if

applicable)

Dimples

Strut

End stile

End stile

Top

section

1/4”-20 x 7/8”

Self drilling screws

Dimples

1/4”-20 x 7/8”

Self drilling

screws

Stru

t

Stru

t

Top fixtures

(if applicable)

Dimples

Strut

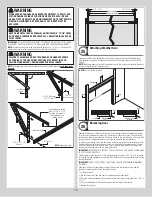

INSTALLATION ON ALL SOLID SECTIONS (EXCEPT TOP SECTION):

Using sawhorses, lay

the section on a flat smooth surface. Starting on the left hand side of the section, align the

lower leafs of the appropriate graduated end hinges over the holes at the top of the end caps

located at the top of the section. Next, align the lower hinge leafs of the #1 center hinges

with the dimples at the center location(s) located at the top of the section. Secure the gradu-

ated end and center hinges to the section using (2) 1/4” - 20 x 11/16” self drilling screws.

Locate and center the strut onto the section surface and up against the bottom edge of the

hinges. Center the strut side to side on the section. Secure strut to section using 1/4” - 20 x

7/8” self drilling screws at each end and at each dimple location(s), as shown.

1/4”-20 x 11/16” Self

drilling screws

#1Center

hinge(s)

#1 Graduated

end hinge

Lower

hinge leaf

Short stem

track roller

End stile

End stile

Bottom section

#1Center

hinge(s)

#1 Graduated end hinge

#1 Graduated end hinge

Lower

hinge leaf

1/4”-20 x 11/16” Self

drilling screws

Dimples

1/4”-20 x 7/8”

Self drilling screws

Strut

1/4”-20 x 11/16” Self

drilling screws

#1Center

hinge(s)

#1 Graduated

end hinges

Lower

hinge leaf

Long stem

track roller

End stile

End stile

Bottom section

#1Center

hinge(s)

#1 Graduated end hinges

#1 Graduated end hinges

Lower

hinge

leafs

1/4”-20 x 11/16”

Self drilling screws

Dimples

1/4”-20 x 7/8”

Self drilling screws

Strut

INSTALLATION ON ALL SECTION WITH WINDOWS (EXCEPT TOP SECTION):

Using

sawhorses, lay the section on a flat smooth surface. Starting on the left hand side of the

section, align the lower leafs of the appropriate graduated end hinges over the holes at the

top of the end caps located at the top of the section. Next, align the lower hinge leafs of the

#1 center hinges / half center hinges with the dimples at the center location(s) located at

the top of the section. Locate and center the strut onto the section surface and on top of the

hinges. Center the strut side to side on the section. Secure strut and hinges to section using

strut clips and 1/4” - 20 x 7/8” self drilling screws at each end hinges and at each dimple

location(s), as shown.

NOTE:

If your Intermediate Section has windows in it and a strut needs to be installed on that

section, strut clips will need to be used to attach it to the section.

10

Содержание 8300

Страница 25: ......