© 2018

14

LDTC2/2 LASER DIODE DRIVER AND TEMPERATURE CONTROLLER

ADDITIONAL TECHNICAL

INFORMATION

This section includes useful technical information on the

following topics:

•

Steps For Replacing The WTC/WLD

•

Proportional Gain & Integrator Time Constant – PI

•

Configuration For Alternate Temperature Sensors

•

Changing The Laser Diode Output Current Range

•

•

Temperature Controller Block Diagram

•

Safe Operating Area Calculation

STEPS FOR REPLACING THE WTC/WLD

Disassemble the LDTC2/2:

1. Remove cables from the unit.

2. Remove screw from top of unit holding the cover down.

3. Lift straight up on the cover to remove it from the base.

4. Remove PCB from the base plate by carefully pulling it

straight up off the corner posts. Be sure not to bend the

pins on the WTC/WLD, which will not come off with the

PCB.

5. Remove the eight screws on the bottom of the baseplate

that attach the WLD and WTC to the baseplate.

6. Use a small screwdriver to separate the WLD and WTC

from the baseplate.

Reassemble the LDTC2/2:

1. Plug the new part(s) into the PCB before attaching it to

the base to ensure that the pins do not get bent.

2. Make sure that the thermal sil pad or thermal paste is in

good shape in order to tightly couple the WLD/WTC heat

spreader to the mounting plate or heat sinking surface.

Replace a questionable sil pad or spread a new thin coat

of thermal paste.

3. Seat the holes on the PCB onto the corner posts and

press PCB into seated position. Install the eight screws

in the WLD and WTC.

4. Install the cover and cables.

PROPORTIONAL GAIN & INTEGRATOR TIME

CONSTANT – PI TERMS

The LDTC2/2 is configured to the mid-range positions

appropriate for most laser diode loads. To adjust these

parameters to optimize the temperature control system time

to temperature or stability, contact Wavelength.

CONFIGURATION FOR ALTERNATE

TEMPERATURE SENSORS

LM335

To use a National Semiconductor LM335 temperature sensor

with the LDTC2/2, attach the LM335 cathode to

and the LM335 anode to SENSOR-. R

BIAS

, shown in

should be changed to 2 kΩ for a bias current of

1mA through the sensor.

The voltage output of the LM335 is 10 mV/K.

NOTE: The ExtTset must be used for setting the temperature

when using the LM335.

AD590

To use an Analog Devices AD590 temperature sensor with

the LDTC2/2, first remove R

BIAS

.

Connect the positive lead of the AD590 to a VDD voltage

supply ≥8 V and the negative lead to the pin

on the LDTC2/2. The AD590 produces a current of 1 μA/K,

giving a transfer function of 10 mV/K with a 10 kΩ resistor

connected between and ground (Pins 8 & 9 on

J3).

RTD

To use an RTD, the bias current resistor R

BIAS

)

must be changed to yield either 1 mA (R

BIAS

= 2 kΩ) or 10 mA

(R

BIAS

= 200 Ω) bias current depending on the temperature

range required. Additionally, reverse the connections to

TEC+ and TEC-.

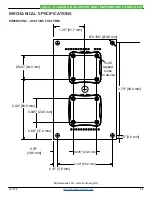

1

1

1

CC

CP

+

ON

OFF

Tset

LIMA

LIMB

ILIM

ISET

+

+

J1

J2

J3

ExtTset Vset PDset

3

2

1

10

9

8

7

6

5

4

3

2

1

12

11

10

9

8

7

6

5

4

3

2

1

R

BIAS

R

35

+

+

+

+

+

Figure 11. Location of Sensor Bias Resistor (R

BIAS

).