IS-HF-AccUViewLEDEx-100125 Rev 0

12

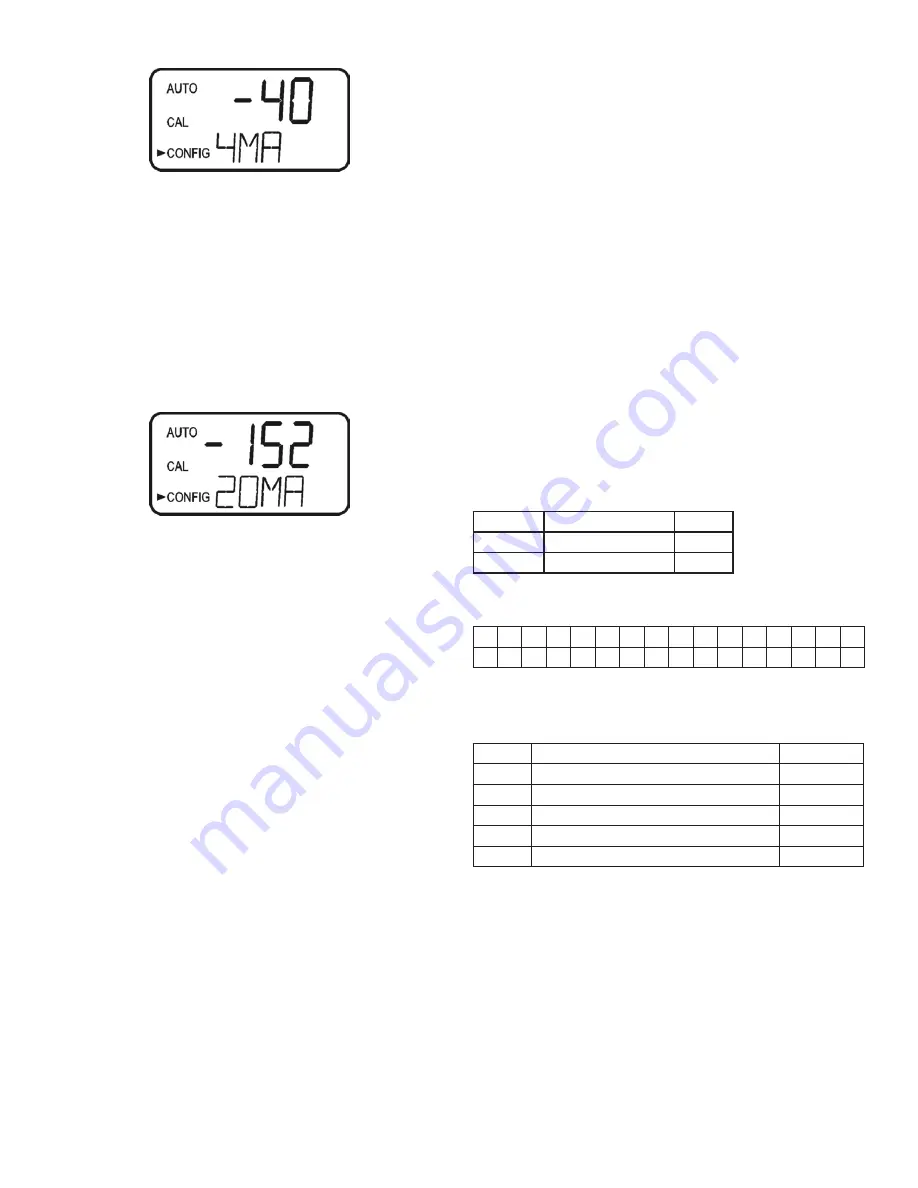

4mA Adjustment

If the 4-20mA setting is turned ON (see section Setting the 4-20mA

Output for more information) the following menu along with the 20mA

Adjustment menu will appear. The first menu outputs a constant

4mA while allowing for a small amount of adjustment. This allows the

operator to make the AccUView LED Ex align with a PLC or SCADA

system. The adjustment limits are ±200 counts or about ±0.2mA. This

setting will differ slightly on each instrument, as each AccUView LED Ex

will be factory set to 4.00mA.

1. Use the

and

buttons to select the desired adjustment for the

4mA adjustment setting.

2. Once the desired adjustment has been selected, press the

button

to set it and move on to the 20mA Adjustment menu.

20mA Adjustment

This menu operates in the same way as the 4mA menu. This menu

outputs a constant 20mA while allowing for a small amount of

adjustment. This setting will be slightly different on each instrument, as

each AccUView LED Ex will be factory set to 20.00mA.

1. Use the

and

buttons to select the desired adjustment for the

20mA adjustment setting.

2. Once the desired adjustment has been selected, press the

button

to set it.

Saving Configuration Settings

If the extended settings are set to

OFF

, pressing the

button will save

all settings and the AccUView LED Ex will automatically return to the

normal

AUTO

mode of the instrument.

If extended settings are set to

On

, after the last menu of the extended

settings, pressing the

button will save all settings and the AccUView

LED Ex will automatically return to the normal

AUTO

mode of the

instrument.

The CONFIG menu may be used at any time to reset or change any

of the parameters. The CONFIG menu may be exited at any point in

the menu by using the MODE/EXIT key. Any features that have been

modified will be saved.

While operating in CONFIG mode, the reading before entering that

mode is held.

Flow Switch

The AccUView LED Ex comes standard with a flow switch installed.

There is an additional menu in the configuration which gives you the

selection of ON or OFF.

If “Low Flow” is enabled, a flow of less than 150ml/minute (.04 GPM)

will cause a screen indication. The flow switch can act on the 4-20mA.

A “Low Flow” will affect the 4-20mA signal based on the set error level.

A modbus register is also set. The condition takes 2-1/2 minutes of low

flow to actuate or restore.

Screen Display - 20mA Adjustment

Modbus Communication

The AccUView LED Ex uses a communication protocol called Modbus.

A company, called Modicon, developed the Modbus protocol for use

with their programmable controllers. Since that time, Modbus has

evolved into a common communication protocol in the industry.

The communication method involves using a master-slave technique,

in which there is one master and several slaves. The AccUView LED

is a slave device. Only the master can initiate queries. These queries

are directed to an individual slave device and the appropriate slave

responds with the requested data.

A broadcast message can be sent to all slaves. The slave devices do

not answer these broadcasts.

There are two transmission modes. These modes are known as

RTU (Remote Terminal Unit) and ASCII (American Standard Code for

Information Interchange).

The AccUView LED can be setup in a network of up to 255 slave

devices. Each device must have a different address (1-255). The

instrument can be set for either RTU or ASCII mode.

Modbus RS-485 Output & Commands

Coils

These single-bit values are readable and changeable from the master.

The data will be returned with the lowest addressed coil in the LSB of

the data. Unused bits in the data will be set to 0. True is a 1 and False

is a 0.

Valid Commands

Code

Name

Broadcast

0x01

Read Coil Status

No

0x05

Force Single Coil

Yes

Format

16-bit word format

MSB

LSB

Bit 15 Bit 14 Bit 13 Bit 12 Bit 11 Bit 10 Bit 9 Bit 8 Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Valid Addresses

00001 - 00XXX

Definitions

Address

Function

Default

00001

Offset added

False

00002

Flow alarm selected

False

00003

Access code enabled

False

00004

Ultrasonic cleaning enabled (if available)

True

00005

Desiccant set as error (True) or warnings (False)

True

Screen Display - 4mA Adjustment