29

Performance data

29.1

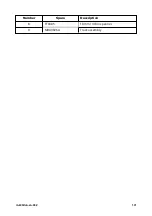

620RE, 620RE4 and 620R performance data

Pumping conditions

All performance figures in this operating instruction have been recorded against peak pipeline

pressures.

This pump is rated to 4 bar (58 psi) peak pressure when fitted with a 620RE, 620RE4 or 620LG pumphead

using high-pressure tubing. However, it will generate in excess of 4 bar (58 psi) peak pressure if the

pipeline is restricted. Where it is important that 4 bar (58 psi) is not exceeded, pressure relief valves

should be installed in the pipeline.

Viscosity handling is maximised by using 4.0 mm wall LoadSure elements with the 620RE and 620RE4

pumpheads.

Flow rates are normalised test values obtained using new tubing with the pumphead rotating clockwise

pumping water at 20 °C with negligible inlet and discharge pressures. Actual flow rates achieved may

vary because of changes in temperature, viscosity, inlet and discharge pressures, system configuration

and tubing performance against time. Flow rates may also vary due to normal manufacturing

tolerances of the tubing. These tolerances will make flow rate variance more pronounced at smaller bore

sizes.

For precise and repeatable performance it is important to determine flow rates under operating

conditions for each new piece of tubing. 620R and 620L family pumpheads' flow rates are directly

proportional to rotor speed. If you wish to run the pump at a speed not shown in the tables below, flow

figures can be reached by dividing the maximum flow shown in the tables below by the maximum rpm

figure, and multiplying the result by your required speed in rpm.

In normal circumstances, rotor and tube life are maximised if the pumphead is run slowly, particularly

when pumping at high pressure. However, to maintain performance at pressures above 2 bar, avoid

running the pumphead below 50 rpm. If low-flow, high-pressure operation is necessary, switching to a

smaller tube is recommended.

STA-PURE Series PCS, STA-PURE Series PFL and Marprene TM tubing are hard to compress when new.

When using tubing made of these materials, the first five pumphead revolutions should be at a speed of

10 rpm or greater. If the pump is run slower, the safety system built into pump drive’s software may

cause it to stop and display an over-current error message.

Note

: Flow rates quoted have been rounded for simplicity, but are accurate to within 5 % - well within

the normal tubing tolerance variation of flow rate. They should therefore be taken as a guide. Real flow

rates in any application must be determined empirically.

132

m-630dun-en-08.2