Troubleshooting

[B2000171_1] - EN / 20.12.11

Page 10 of 12

Subject to change without notice.

8

Troubleshooting

CAUTION

Personal injury or property damage during

troubleshooting!

Problems without a reference to a quali-

fied specialist or certified electrician may

be rectified independently.

Other problems are only to be dealt with

by a qualified specialist or certified electri-

cian.

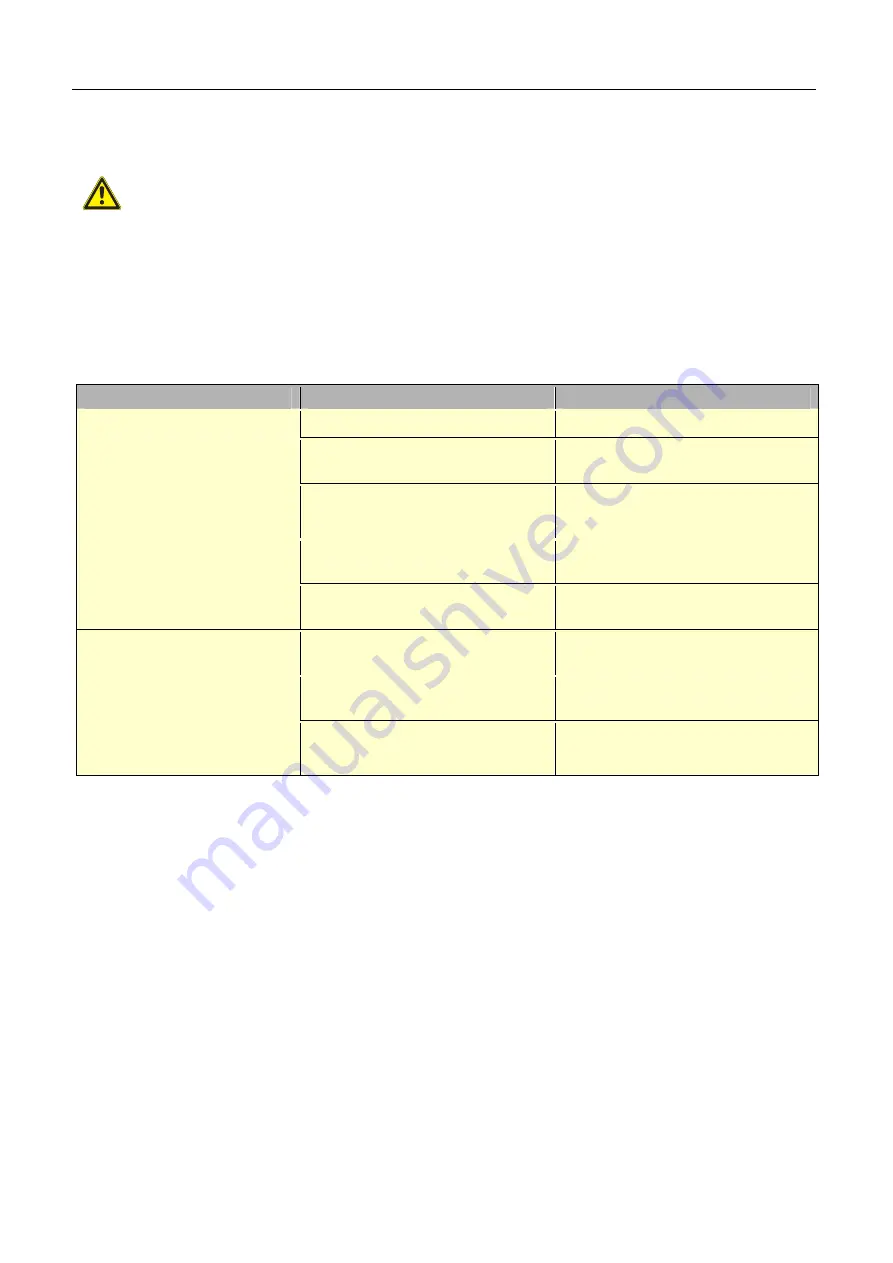

Problem

Possible causes

Remedy

Motor is not operating

Motor is malfunctioning

Motor change (specialist only)

On-site motor connection is incorrect

Reconnect as per wiring diagram (certi-

fied electricians only)

Motor thermal protection switch has

triggered

Wait 10 to 15 minutes, then try again

Then try again

There is no current

Check the power supply fuse (certified

electricians only)

A higher-level control command is pre-

sent

Await switch on/off delay

Drop rail does not move to the

required limit position

The limit positions on the motor are

incorrectly set

Readjust the motor (specialists only)

Drop profile is moving at a slant

The guide rails are not aligned (uneven

substructure)

Align the guide rails (specialists only)

The guide rails are not correctly posi-

tioned

Check the guide rails

Correct if necessary (specialists only)

Tab. 2:

Overview of possible problems