Rev. 1.2

Assembly Instructions - Spray Valve SMS-02

Page 19 of 34

Walther Systemtechnik GmbH

– D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de

– [email protected]

10 Appendix

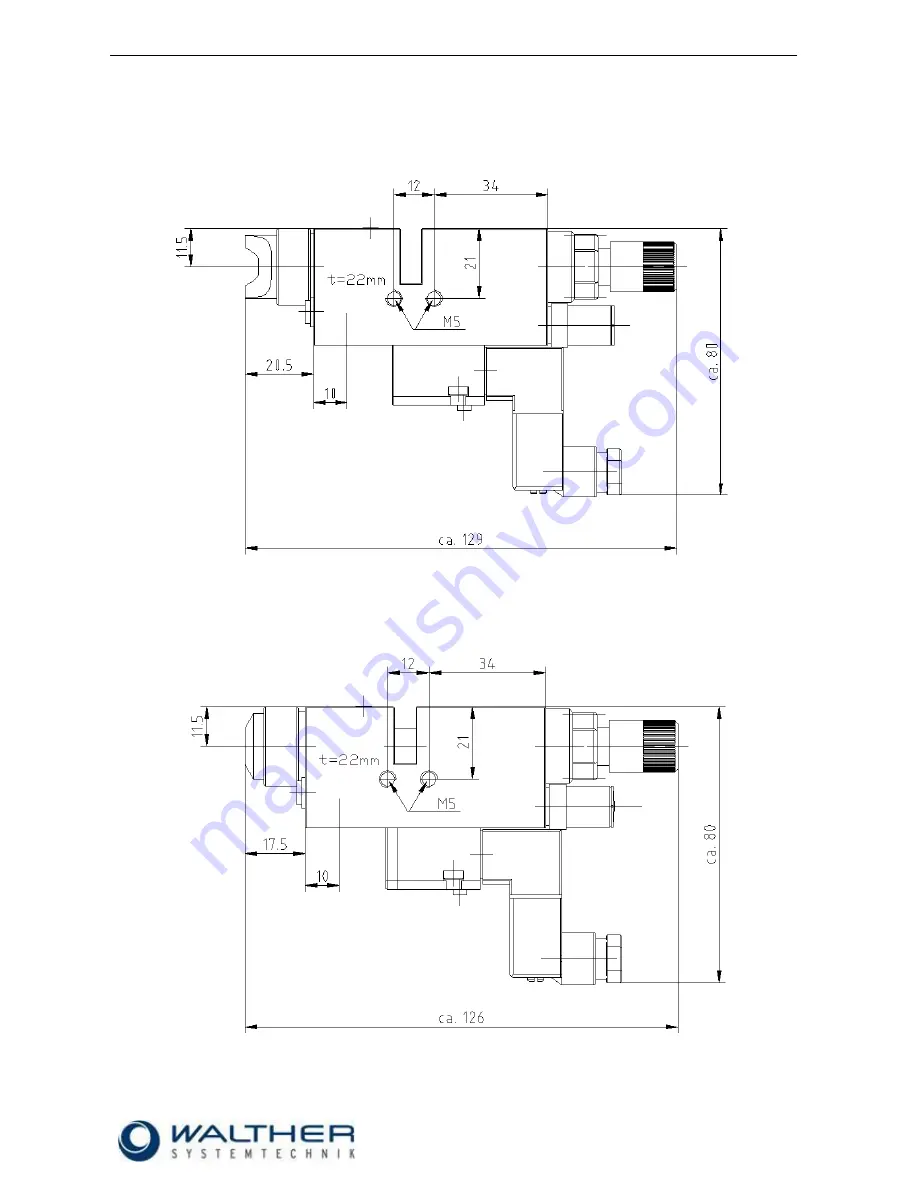

10.1 Dimensioned Drawing (Flat jet)

10.2 Dimensioned Drawing (Round jet)