Rev. 1.0

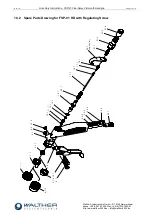

Assembly Instructions - FSP-01 Fine-Spray Pistol with Handgrip

Page 9 of 19

Walther Systemtechnik GmbH

– D 76726 Germersheim

phone: +49 (0)7274-7022-0 fax: +49 (0)7274-7022-91

http://www.walther-2000.de

7 Taking out of Service

7.1 Short Interruption

A short interruption (15 min or more) has to be followed by a fine spraying.

IMPORTANT

Please follow the Operating Instructions!

7.2 Long-term Interruption

The following has to be observed for a long-term interruption of the device/machine:

Depressurize material supply lines

Take off air cap (3) and clean nozzle (2) with a special thinner and a soft cloth. Make sure that no cloth

fibers are left on the nozzle tip.

IMPORTANT

Please follow the maintenance instructions!

7.3 Final Shutdown of Device

The following is important for a shutdown of the machine / device:

Clean spray pistol with a special thinner.

IMPORTANT

Please follow the maintenance instructions!

8 Maintenance and Repair

8.1 General Information

CAUTION

Before starting any maintenance or repair work, ensure that all air-operated tools are

depressurized and disconnected from the air supply.

Before opening the spray valve it must be disconnected from the air and fluid supply.

Otherwise, ejected components can cause injuries

The

FSP-01

Fine-Spray Pistols are high precision tools. Always keep clean and observe minimum

instructions to maintain a long life of the valve. Always use clean and filtered material only. The control air

must also be clean and should be slightly oiled, if necessary. Maintenance also depends on the individual

operating conditions and the type of media used.

Particularly when using the spraying pistol as a color marking device, the spraying cap should be removed

before longer standstills. The spraying nozzle should be cleaned with a soft cloth and the special dilution.

Please make sure that no cloth fibers remain on the nozzle tip. Then spray the valve free by keeping the

manual switch of PLC control or the auxiliary switch on the 3/2-way solenoid valve (green button) pressed for

some time.