36

37

6

Cleaning and Maintenance

6.1

Safety Instructions

•

Prior to any servicing and repair work: Make sure that the spray gun is in

unpressurised condition, i.e. all air and material inputs must be shut off - if not,

imminent Risk of Injury .

•

No open fires and naked lights as well as smoking are allowed in the work

area. This is a major requirement to prevent the euer present risk of fire and

explosion, particularly when spraying readily flammable media such as, for

example cleaning solutions, etc.

•

It is important that all processing specifications and safety warnings issued by

the manufacturer of cleaning media are duly complied with. Remember:

Aggressive and corrosive media represents risks and hazards to personal

health.

6.2

Cleaning - Complete

The spray gun should be frequently cleaned and lubricated so as to ensure a long

service life and functional reliability. Cleaning of the gun only with cleaning solutions

recommended by the manufacturer of the spraying material used at the time. It is

im-portant to make sure that cleaning solutions do not contain any of the following

constituents:

•

halogenated hydrocarbons (e.g. 1,1,1-trichloroethane; methylene chloride, etc.)

•

acids and acidiferous cleaning solutions

•

regenerated solvents (so-called cleaning dilutions)

•

paint removers

The above constituents cause chemical reactions with electroplated components

resulting in corrosion damage.

WALTHER Spritz- und Lackiersysteme is not liable for any damages resulting from

improper treatement of the gun.

Clean the spray gun

•

prior to each change of the spraying medium.

•

at least once a week.

•

as often as may be required by the spraying medium handled and the resultant

degree of fouling.

Caution

Never immerse the spray gun in solvent or any other cleaning solution as such

measure is highly likely to affect the functional reliability and efficiency of the gun.

Caution

Do not use any hard, pointed or sharp-edged objects when cleaning the spray gun.

Any damage of the precision-made parts are likely to affect your spraying results.

1. Dismantle the spray gun (see

5.5 Retooling the Spray Gun

).

2. Use a soft brush together with a compatible cleaning solution to clean the air

cap and nozzle.

3. Use a suitable cloth with a compatible cleaning solution to clean the gun body

and all remaining parts.

4. Apply a thin film of the appropriate grease type/grade to the:

•

sealing collar of the piston

•

O-ring of the piston

•

material control needle

•

needle spring

•

inside of the gun body

Make sure to use a non-acidic, non-resinogenic grease type/ grade and apply

same with a soft brush. Assemble the spray gun in reverse order.

6.3

Cleaning - Routine

The spray gun need not necessarily be dismantled for cleaning if and when the

spraying medium is changed in regular intervals or upon termination of work

(depending, of course, an the material used).

Notice

lt is recommended practice to clean and lubricate the spray gun frequently in

accordance with Chapter

6.2 Cleaning - Complete

, as this will greatly help towards

ensuring a Jong service life and functional reliability.

The following requirements must be met before the routine cleaning work can be

performed:

•

the material tank must be clean and then filled with a compatible cleaning

solution.

•

cleaning solution should neuer be sprayed - yet the material pressure must be

available at the gun.

The spraying system must be in Operation if a spray gun is to be cleaned.

1. Take the spray gun into Operation (see

5.2 Starting / Stopping Requirements

).

2. Do not stop the spray gun until clear cleaning solution emerges from the nozz-

le.

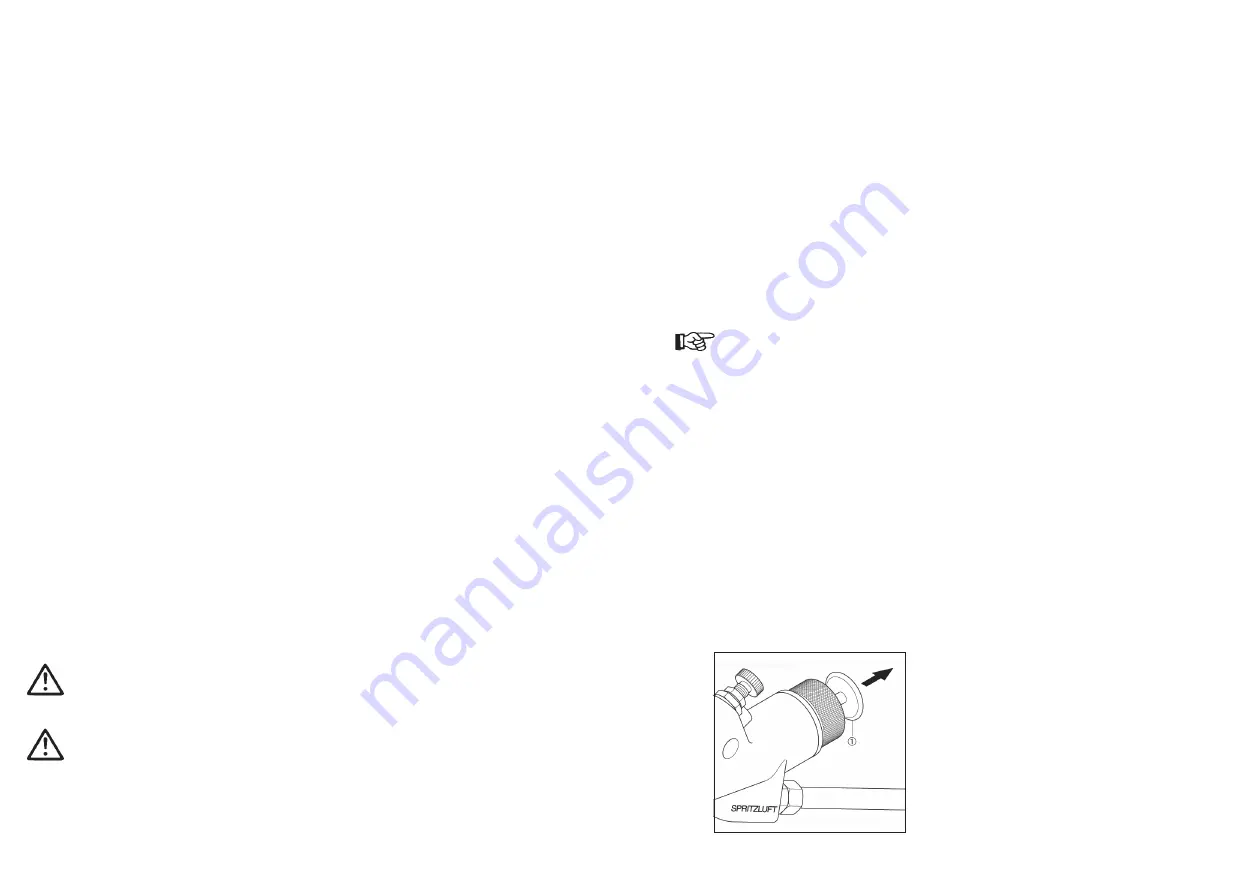

Only WA XV needle-pull / WA XV-HVLP

The material Input can be released by hand so that the complete spraying system

must not be taken into operation.

1. Pull the disk

at the end of the spray gun back.

The material inlet is now open and both the

material duct and the material needle will be

washed clean.

2. Do not let go of the disk

until clear cleaning

solution emerges from the nozzle.

All pressures should now be removed from the

complete spraying system - which should be left in

this condition until it is taken into operation again.