29

6.1

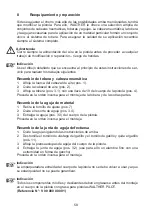

Correcting spray pattern flaws

The following table shows the settings you can use to change the spray pattern.

Spray pattern

test

Fault

Required adjustment

Spray pattern is split in

the centre

• setting a wider spray pattern

Spray pattern is too thick

at the ends

• Setting a more rounded spray

pattern

The spray pattern shows

rather large droplets

• Increase the nozzle air pres-

sure

Material application in

the centre of the spray

pattern is very thin

• Decrease the nozzle air pres-

sure

Spray pattern is split in

the centre

• Increase the nozzle diameter

• Reduce nozzle air pressure

• Increase material pressure

Spray pattern is very

spherical

• Reduce material pressure

• Increase nozzle air pressure

7

Troubleshooting and fault rectification

Warning

Prior to any seervicing and repair work: Make sure that the spray gun is in unpres-

surized condition, i.e. air input must be shut off - if not, imminent risk of injury.

Fault

Cause

Remedy

Gun is dripping

Material needle or nozzle soiled or

damaged

Spring bushing (N° 6) turned too

far to the back

• Clean or replace

• Adjust by turning

clockwise

Pulsating or

unsteady jet

Not enough material in material

tank

Cup is tilted too much during

spraying operation

Material nozzle loose or damaged

• Top-up material level

• Keep it level

• Fasten or replace

Gun keeps blo-

wing in off-position

Valve spring (N° 5.3) or

valve cone (N° 5.2) damaged

• Replace

desired spray result