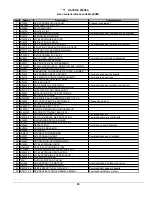

8

BLOWER SPEED ADJUSTMENTS

(A/C MODE, 4 SPEED MOTOR)

A/C CAPACITY

(TONS)

RECOMMENDED

BLOWER SPEED

2.5

MED-LOW

3.0

MED-HIGH

4.0

HIGH

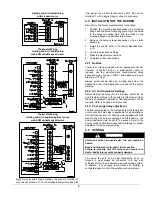

To effect the adjustment, the RED (for heating) and BLUE (for

cooling and heat pump) wires can be changed on the motor.

Also, refer to the position of the wires on the electronic board

of the unit and consult the wiring diagrams. If the heating and

air conditioning speeds are the same, the RED wire must be

moved to “UNUSED LEADS” on the electronic board and the

jumper provided with the BLUE wire must be used between the

“HEAT” and “COOL” terminals.

The blower start/stop delays can be adjusted by positioning the

DIP switches on the electronic board as shown in the following

figures. However, the recommended adjustments are 60

seconds blower ON delay and 2 minutes blower OFF delay.

Blower “OFF” delay

Board # ST9103A

Blower start / stop delays

Board # 1158

2.11 SUPPLY

AIR

ADJUSTMENTS

(ECM

VARIABLE

SPEED

MOTORS)

On units equipped with ECM variable speed blower motors,

the air supply must be adjusted based on heating/air

conditioning output. The start/stop delays of the blower must

also be adjusted by positioning the DIP switches on the

electronic board. Refer to the following tables and the wiring

diagram in this manual for the proper settings:

HEATING MODE

SW1 – HEAT

DIP Switch Positions

1 2

POSITION

Input

USGPH

OFF OFF

A

0.68

ON OFF

B

0.80

OFF ON

C*

0.68

ON ON D*

0.80

* Alternate adjustment for a higher air temperature rise.

AIR CONDITIONING MODE

SW2 – COOL

DIP Switch Positions

1 2

POSITION

Output

Tons

OFF OFF

A

4.0

ON OFF

B

3.5

OFF ON

C

3.0

ON ON

D

2.5

CFM ADJUSTMENTS – ALL MODES

SW3 – ADJ (Adjustment)

DIP Switch Positions

1 2

POSITION

CFM HTG.

% increase

or decrease

CFM A/C

% increase

or decrease

OFF OFF

A

0%

0%

ON OFF

B

+10%

+10%

OFF ON

C

-10%

-10%

ON ON

D

N/A

0%

DELAY ADJUSTMENTS – HEATING MODE

SW4 – Delay

DIP Switch Positions

1 2

POSITION

Input

USGPH

OFF OFF

A

0.68

ON OFF

B

0.80

OFF ON

C*

ALL

ON ON D*

ALL

* Alternate adjustments for both input rate (refer to air flow table).

2.12 INSTALLATION

OF

ACCESSORIES

WARNING

Electrical shock hazard.

Turn OFF electrical power at the fuse box or service

panel before making any electrical connections and

ensure a proper ground connection is made before

connecting line voltage.

Failure to do so can result in death or bodily injury.

2.12.1 Humidifier

(HUM)

The 120 VAC HUM terminal on the electronic board of the

blower is tied directly to terminal 8 of the 9-terminal

connector of the electronic board. It supplies 120 VAC

electric power when the burner is in operation.

A 24 VAC signal can also be supplied from the W and C

terminals on the blower electronic board to activate a

switching relay.

Also refer to the instructions supplied with the accessory.

2.12.2 Electronic Air Cleaner (EAC)

The EAC terminal on the electronic board supplies 120

VAC when the blower is operating in the heating or air

conditioning mode. This signal can be used to activate an

electronic air cleaner that is not equipped with an air flow

switch. If the cleaner is equipped with an air flow switch,

the S terminal on the electronic board can be used to

provide a constant supply of 120 VAC.

Also refer to the instructions supplied with the accessory.

Содержание OLR112A16A

Страница 18: ...18 Figure 2 Dimensions de la fournaise...

Страница 19: ...19 Figure 3 Diagramme lectrique Moteur 4 vitesses PSC...

Страница 20: ...20 Figure 4 Diagramme lectrique Moteur vitesse variable ECM...

Страница 21: ...21 COMPOSANTES ET PI CES DE REMPLACEMENT...

Страница 22: ...22 LISTE DE PI CES Avec moteur 4 vitesses PSC B50093B...

Страница 24: ...24 LISTE DE PI CES Avec moteur vitesse variable ECM B50094B...

Страница 41: ...16 Figure 2 Furnace dimensions...

Страница 42: ...17 Figure 3 Wiring Diagram 4 Speed Motor PSC...

Страница 43: ...18 Figure 4 Wiring Diagram Variable Speed Motor ECM...

Страница 44: ...19 COMPONENTS AND REPLACEMENT PARTS...

Страница 45: ...20 PARTS LIST With 4 speed motor PSC B50093B...

Страница 47: ...22 PARTS LIST With variable speed motor ECM B50094B...