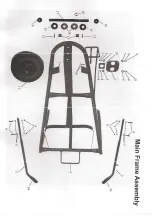

CONTENTS OF THE PACKING CASE

1 x Machine body complete

2 x Handle bars

1 x Spray Boom assembly

1 x Plastic bag containing:

4 x Handle bolts, wingnuts and washers

2 x Cable Clamps

1 x Instruction manual and Warranty

ASSEMBLY INSTRUCTIONS

The RAMBLER sprayer has been factory

tested prior to packing and only requires

the handles and the spray boom assembly

to be fitted.

Fit the handlebars into position using the

nuts, bolts and washers from the fixing bag.

The boom assembly can be fitted to the

main frame in two positions. The upper

position should be suitable for most

purposes. Take the boom assembly and

attach it to the main frame by using the

clamps. The boom is marked showing its

centre position, and this should be carefully

aligned into the centre of the fixing clamp.

BEFORE tightening the clamp the machine

should be lifted into its normal working

position and the boom nozzles checked to

ensure they are parallel to the ground.

Adjust the boom position and rotation as

necessary, re-check, then tighten the clamp

fixings. Attach the inlet wing nut to the

boom inlet housing. The machine is now

ready for testing.

TESTING

A trial run should be carried out on a dry

concrete surface to check that the nozzles

are in alignment. This should be carried out

using clean water to ensure everything is in

working order.

Half fill the container with cold water,

replace the filler cap & filter and move off at

a steady working place similar to the speed

of mowing.

This will prime the pump mechanism and

water will spray from the nozzles, showing

that all air has been bled from the system.

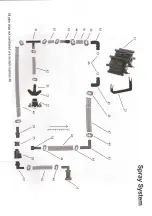

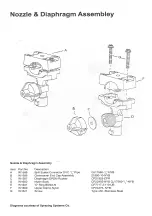

If an airlock remains in the system, unscrew

the two diaphragm check valve caps and

push the machine until water flows through

the system. Tighten the two caps and then

push. The machine will then start to spray.

DO NOT over tighten the diaphragm caps.

They are fitted in order to clear the spray

system of air & other small blockages.

OPERATING INSTRUCTIONS

When filling the machine, add sufficient

liquid treatment to cover the area needing

treatment or a pro-rata amount if only part

filling. Pay careful attention to which colour

nozzle is fitted at the time of spraying to

avoid any over or under application of

chemical. Always follow the chemical

manufacturers instructions relating to the

specific area. In many instances dilution

rates of chemicals are not critical, but in

some cases where a greater volume of

water is needed, then two x half strength

applications are recommended, spraying

where possible in a chequer board fashion

in North to South and East to West

directions.

SPRAY WIDTH

The RAMBLER has a spray width of 40

inches (1016mm). In common with all

Walkover sprayers, the spray pattern tails

off on the extreme edge of the treated

swath which is compensated for when

treating the return track. You must therefore

always ensure your return track is 40”

(1016mm) from the datum point of your

previous pass to achieve correct coverage.

A set of red nozzles are provided with the

machine. Nozzles giving alternative

coverage areas for the 25 litre (5.5 gallons)

loading as follows:

(a) With standard nozzle fitted, Red

ANDT 2.0, one full tank covers 825

sq. metres (1000 sq. yards)

equivalent to 298.6 litres/hectare

(26.6 gallons/acre)

(b) Alternative nozzle, Grey

TF VP 3

delivers to one full tank 500 sq.

metres (670 sq. yards) equivalent

to 449 litres/ hectare (40

gallons/acre)

N.B

The coverage areas for each nozzle

may vary plus or minus 5% depending on

the speed of operation and variations of the

terrain.