68

Maintenance Instructions

ADJUSTMENTS

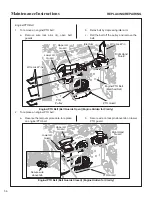

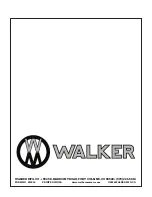

Step 2 -

Blade Brake Band Adjustment

After the maximum pulley travel is set, adjust the

working travel of the clutch idler pulley by adjusting

the brake band nut and make the following adjust-

ment as needed:

1. Adjust the blade brake band, using the adjust-

ment nut until pulley travel is approximately

5/8 in. to 3/4 in. (16 mm to 19 mm) from en-

gaged to disengaged.

NOTE:

As blade brake band/drum wears, pulley

travel will increase and it will be necessary to

adjust the blade brake band nut to maintain

these dimensions.

CLUTCH DISENGAGED

CLUTCH ENGAGED

5/8 in. to 3/4 in.

(16 mm to 19 mm)

Clutch Idler Pulley Travel Adjustment

Blade Brake

Band Adjustment Nut

Blade Brake

Band

Chassis Mount

(Ref)

Blade Brake Band Adjustment

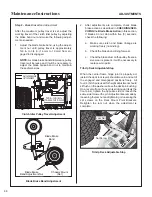

2. After adjustments are complete, check blade

brake action as described in

CHECKING/SER-

VICING

the

Blade Brake Action

in this section.

If blades do not stop within five (5) seconds,

check the following:

a. Make sure clutch and brake linkage are

working freely (no binding).

b. Check the brake band lining for wear.

c. Check the brake drum on the pulley. If exces-

sive wear is present, it will be necessary to

replace worn parts.

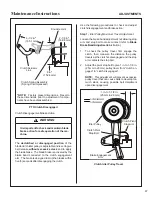

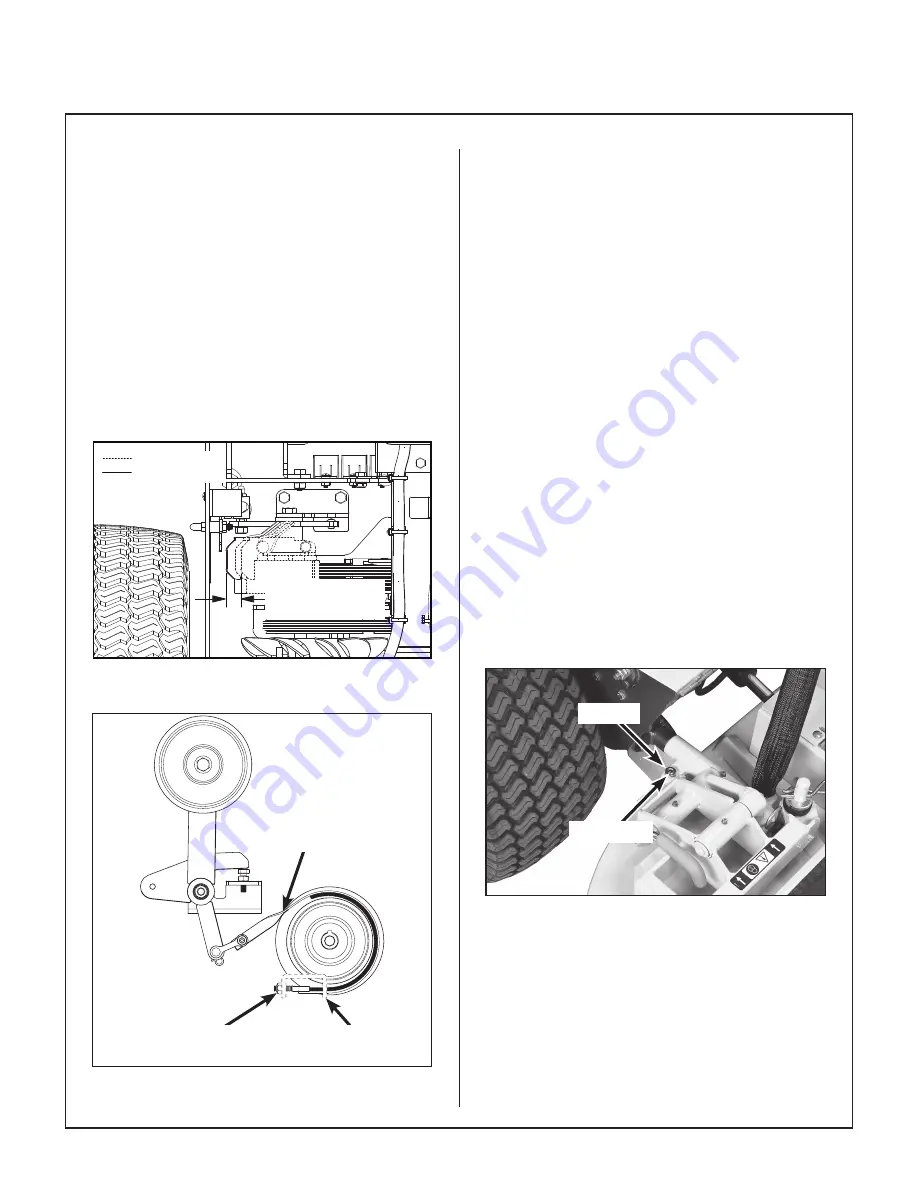

Tilt-Up Deck Adjustable Stop

When the carrier frame hinge joint is properly ad-

justed, the deck lock levers should move in and out of

the engaged and disengaged positions freely. All

four (4) hitch pins used for height adjustment should

sit flush on the washers above the deck pin bushing.

On a level surface, if any pin is sticking up (likely the

front pins), tighten the opposite side or loosen the

same side to lower the pin. Adjustments are made by

loosening the jam nut and tightening or loosen ing the

set screws on the Deck Mount Pivot Brack

ets.

Retighten the jam nut when the adjustment is

complete.

Set Screw

Jam Nut

Tilt-Up Deck Adjustable Stop

Содержание B18

Страница 73: ...69 Operator s Notes...

Страница 74: ...70 Operator s Notes...