500.0037-A

4

Technical alterations reserved

2.2.3.

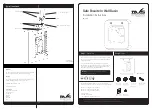

Anchoring hole dimensions

In order to drive the supplied drop-in anchor into the building wall or building floor at the

assembly location in advance, please consult the dimensions in the following figure for

drilling pattern for the WALDIS Basic 480.

2.2.4.

Procedure

The safe is delivered with 2x cylinder screws with an M12x30 internal hex (DIN 912,

strength grade 8.8), 2x M12 washers (DIN 125 A) and 2x M12x50 drop-in anchors.

If it is not possible to use the installation material specified or it is not possible to anchor

the safe, please consult your property insurance provider to find an alternative anchoring

solution.

Follow this procedure to anchor the safe into the building wall or floor:

1.

Draw the drilling pattern on the desired position and then drill the anchoring holes with

Ø15 concrete drill and an impact drill.

➔

The Ø15 drill hole must be at least 54 mm (from the wall/floor) or at least 84 mm

(from the safe’s

interior wall) deep.

2.

The EA2 M12x50 drop-in anchor can be hammered in once all anchoring holes have

been drilled.

➔

Please consult the manufacturer’s information sheet for hammering in the Fischer

EA2 M12x50 drop-in anchor (Fischer no.: 48406).

3.

Align the safe with the installation holes in the building wall or the building floor.

4.

If the safe is to be anchored to the building wall, it has to be evenly hammered into the

wall evenly.

5.

Level out the safe so that the door stands still in any position and does not start to

swing in one direction (open or closed) on its own.

➔

To do this, place small hardboards (Pavatex) under the corners required.

Front view (without door)

for rear wall anchoring

View from above (without door)

for floor anchoring

120

200

220

240

18

1,

5