38

VERSION 05/2018

ORDER NUMBER DOC 2312956

GA 4000ACIC

Pressure Relief Procedure:

1. Turn compressed air regulator for shaping and atomizing air on the superordinate control to "0".

2. Close the compressed air supply on the material side upon the product pressure generator.

3. Open product pressure relief valve (see system description) and relieve pressure from the system.

4. Leave product pressure relief valve open.

If the pressure is still not completely relieved after this:

– If the nozzle is obstructed: loosen the union nut, remove the air cap and nozzle to release remaining

pressure.

– If product hose is obstructed: slowly loosen the hose connections to release the remaining pressure.

Note:

Always follow the procedure described above if pressure relief is specified in the instructions.

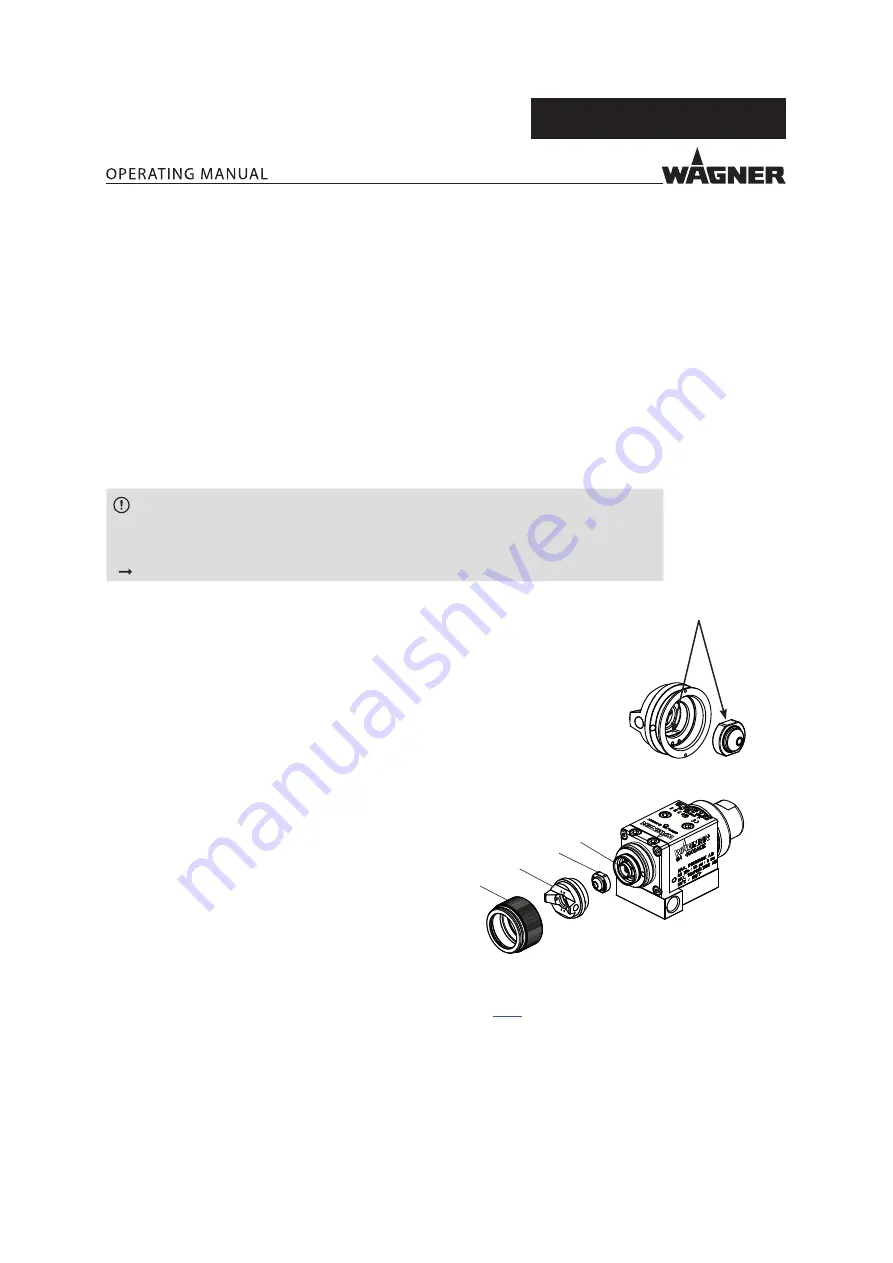

7.2.4 CHANGING AIRCOAT NOZZLE

NOTICE

Defective AirCoat nozzle!

Insufficient paint application quality.

Do not use sharp-edged objects to treat carbide on the AirCoat nozzle.

1. Relieve the pressure of gun and device.

B_03071

X

B_06654

A

B

C

D

2. Secure gun (remove the control air hose).

3. Unscrew union nut (A).

4. Remove air cap (B).

5. Press AirCoat nozzle (C) out of air cap (B) by

hand and treat with cleaning agent until all

remaining paint has been dissolved.

Assembly:

6. Fit AirCoat nozzle (C) in nozzle seal (D).

7. Fit air cap (B) over nozzle (C).

Note the flattened parts (X) on the nozzle and

in the air cap.

8. Fit the union nut with nozzle guard (A) and

tighten by hand.

7.2.5 CLEANING AIRCOAT NOZZLE

For disassembly and assembly of AirCoat nozzles, see Chapter

.

The AirCoat nozzle (C) can be placed into a cleaning solution which has been recommended

by the paint manufacturer.

Содержание GA 4000ACIC-S

Страница 1: ...Version 05 2018 GA 4000ACIC S GA 4000ACIC R AirCoat Automatic spray gun II 2G X B_06647...

Страница 2: ......

Страница 66: ......

Страница 67: ......