Maintenance

Maintenance plan 9.2

39

[en-US] | 01/2023 | 5100069895 | WP | Operator’s Manual

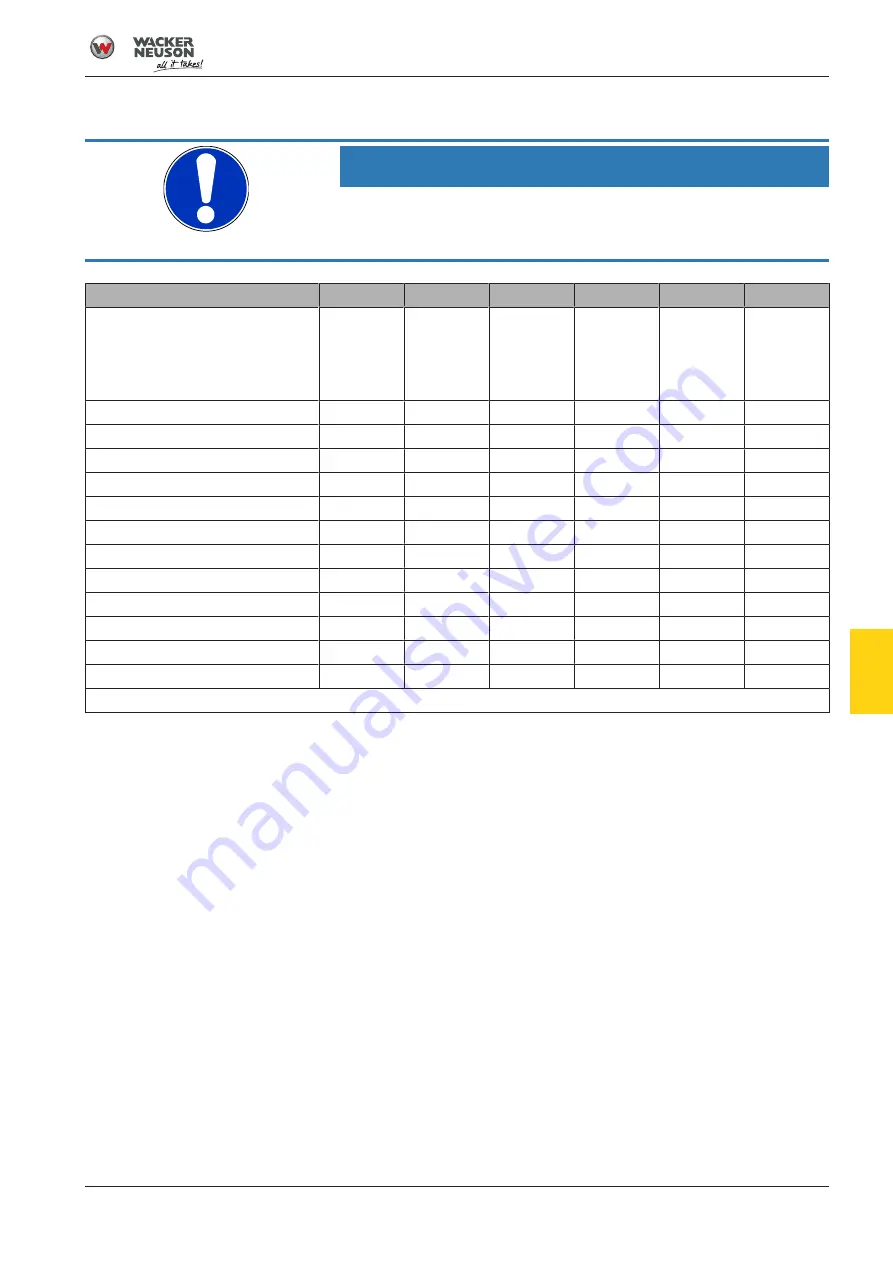

9.2

Maintenance plan

NOTICE

Danger of engine damage!

►

When commissioning new machines, an oil change must be carried

out once after 20 operating hours.

Maintenance work

daily

monthly

100 h

125 h

300 h

500 h

Clean the machine.

• Visual check for complete-

ness.

• Visual check for damage.

●

Check engine oil fill level.

●

Check air filter intake area.

●

Check screw connections.

●

Clean and check air filter.

●

Check V-belt tension.

●

Change engine oil.

●

Clean fuel filter.*

●

Cleaning the deposit cup.

●

Check spark plugs.

●

Check rubber buffer .*

●

Check valve clearance.*

●

Replace fuel filter.*

●

* Have this work carried out by a service partner.

9.3

Maintenance work

Carrying out preparations:

1.

Place the machine on a level surface.

2.

Decommissioning the machine.

3.

Let the machine cool down.

9.3.1

Cleaning the machine

Observe the following when cleaning the machine with a high-

pressure cleaner:

1.

Do not aim high-pressure cleaner directly at air intake area and

electrical components.

2.

Do not hold the high-pressure cleaner too close to the machine in

order to avoid damage to labels and sensitive components.

9