Maintenance

BS 50-4

wc_tx000309gb.fm

32

6.4

Lubrication

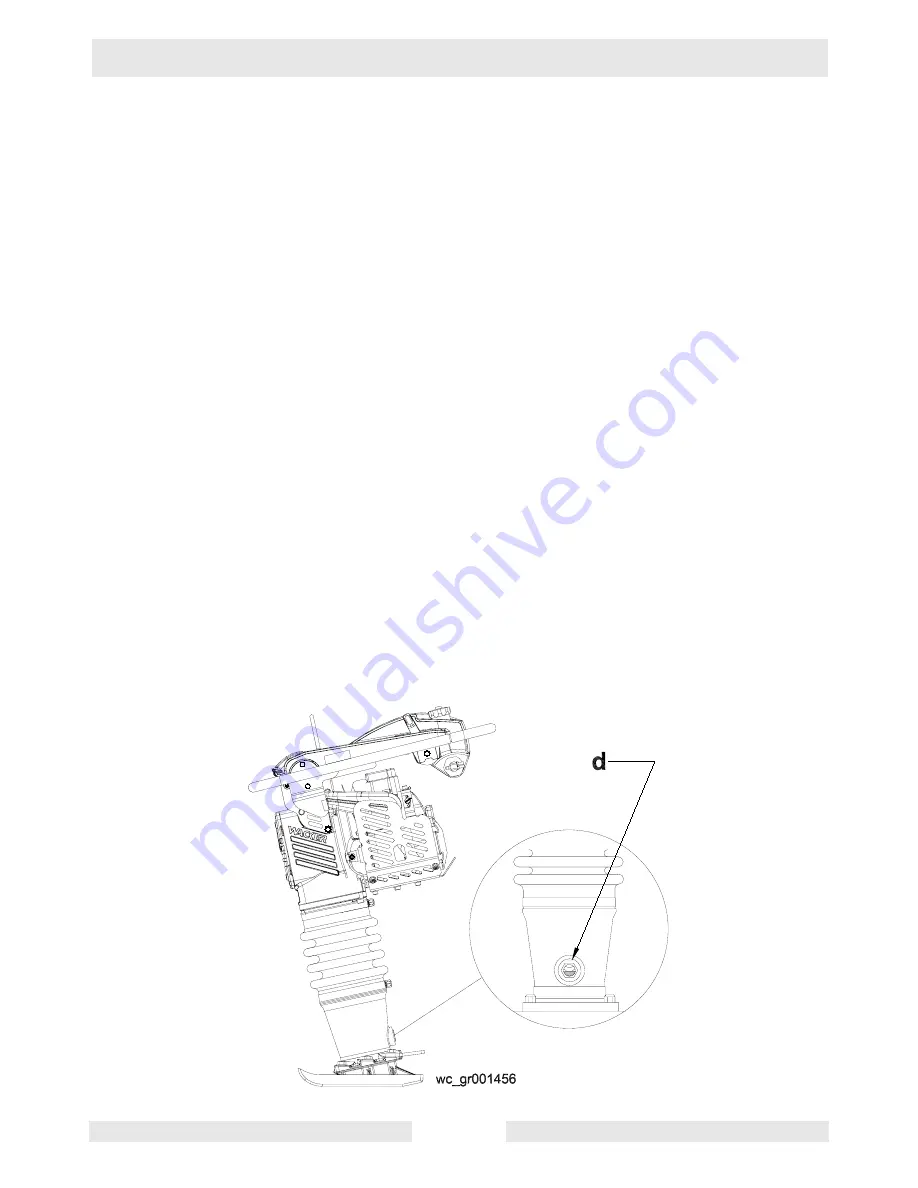

See Graphic: wc_gr001456

Ramming system

Check oil level:

6.4.1

Place the rammer so it is resting on its shoe on a level surface.

6.4.2

Check the oil level through oil sightglass

(d)

. Proper ramming system

lubrication is indicated when approximately 1/2–3/4 of the sightglass is

full.

6.4.3

If the oil is not visible, oil must be added through the sightglass port.

Tilt rammer forward and remove sightglass

(d)

. See

Technical Data

for oil quantity and type.

6.4.4

Wrap the sightglass threads with teflon tape. Install the sightglass

(d)

.

Torque to 9 Nm (6 ft.lbs.).

Oil change:

6.4.1

To drain oil, remove sightglass

(d)

and tilt the machine back until it is

resting on its handle.

Note:

In the interests of environmental protection, place a plastic sheet

and a container under the machine to collect any liquid which drains

off. Dispose of this liquid in accordance with environmental protection

legislation.

6.4.2

Remove sightglass

(d)

and fill with oil. See

Technical Data

for oil

quantity and type. Wrap the sightglass threads with teflon tape. Install

the sightglass

(d)

. Torque to 9 Nm (6 ft.lbs.).