10

D

ESCRIPTION

U

NITS

MR 820

MR 930

MR 1020

MR 1040

MR1130

A

IR

OR

N

ITROGEN

A

N

A

N

A

N

A

N

A

N

Input Voltage

V

3 x 400 (Supply tol10%, -10%)

Frequency

Hz

50/60

Start-Up power

kVA

54

55

55

56

56

Slow Start-Up power

kVA

44

44

44

44

44

Power required at setpoint (depending on

configuration, load and setpoints)

kVA

9

10

10

11

11

Weight machine (maximum)

kg/lb

2300/5071

2500/5522

2200/4850

2700/5952

2200/4850

2700/5952

2700/5952

2900/6393

2700/5952

2900/6393

Force per leveling foot

N

5750

6250

6250

6750

6250

6750

6750

3625

6750

3625

Pressure per leveling foot

N/cm²

90.75

98.64

98.64

106.53

98.64

106.53

106.53

57.21

106.53

57.21

Pressure per leveling foot

N/inch²

585

6.36

6.36

687

6.36

687

687

369

687

369

Nitrogen requirements minimum (only for

nitrogen machine)

bar/PSI

4.8 / 70

Nitrogen supply, maximum rate

m

3

/hr / cfh

50 / 1766

Nitrogen connection type

1/2” female NPT

Air Mode-No GRS - Exhaust volume at

single connection point (maximum)

m³/hr / cfm

450 /265 @ 300Pa

Air Mode-GRS-Nitrogen - Exhaust volume

at single connection point (maximum)

m³/hr / cfm

20 0/ 118@ 100Pa

Exhaust for Fast Cool Down (FCD) requires

two exhaust ports

m³/hr / cfm

800 / 470 @ 300

Exhaust connection

mm / inch

165 / 6.50

Clearance for operate & maintenance

front,-, infeed,- and outfeedside

mm / inch

120 / 47.25

Clearance for operate & maintenance

backside

mm / inch

150 / 59.05

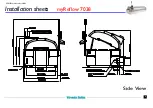

Installation sheets

myReflow 7038

VERSION November 2009

Содержание 42284

Страница 4: ...iv...

Страница 8: ......

Страница 24: ...INSTALLATION 8 CHAPTER 2 2 7 INSTALLATION SHEETS AND REQUIREMENTS see next pages...

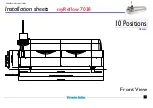

Страница 25: ...1 Installation sheets 10 Positions Front View MR820A myReflow 7038 VERSION November 2009...

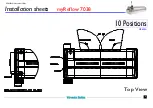

Страница 26: ...2 Installation sheets myReflow 7038 VERSION November 2009 Top View 10 Positions MR820A...

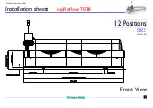

Страница 27: ...3 Installation sheets myReflow 7038 VERSION November 2009 12 Positions MR820N MR930A MR1020A Front View...

Страница 28: ...4 Installation sheets myReflow 7038 VERSION November 2009 12 Positions Top View MR820N MR930A MR1020A...

Страница 30: ...6 Installation sheets myReflow 7038 VERSION November 2009 14 Positions Top View MR930N MR1040A MR1130A MR1020N...

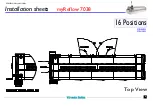

Страница 31: ...7 Installation sheets myReflow 7038 VERSION November 2009 16 Positions MR1040N MR1130N Front View...

Страница 32: ...8 Installation sheets myReflow 7038 VERSION November 2009 16 Positions MR1040N MR1130N Top View...

Страница 33: ...9 Installation sheets myReflow 7038 VERSION November 2009 Side View...