Viessmann Werke GmbHĂ&ĂCo

DĆ35107 Allendorf

Tel:

+49 6452 70Ć0

Fax:

+49 6452 70Ć27Ă80

www.viessmann.de

Viessmann Limited

Hortonwood 30, Telford

Shropshire, TF1 7YP, GB

Tel:

+44 1952 675000

Fax:

+44 1952 675040

email: [email protected]

28

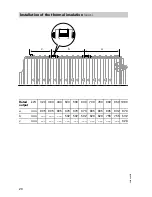

Burner installation

Burner installation and adjustment:

Separate burner documentation.

If the burner connection was not

prepared at the factory, adjust the

blast tube aperture and the fixing

holes on the enclosed blanking plate.

H

Max. blast tube aperture

∅

Ă360Ămm.

Cut out the insulating mat in the

burner door according to the blast

tube diameter.

H

After the burner installation, seal

the annular gap between the flame

tube and the insulating block with

the flame tube gasket supplied.

Please note:

The flame tube must protrude at least

125Ămm from the front edge of the

burner flange into the boiler.

To safeguard perfect function,

maintain the required minimum

flame tube length.

Important notes on commissioning

For commissioning and adjustments, see the service instructions for

boiler, burner and boiler control unit.

Printed

on en

vironmentally friendly

,

chlorine-free bleac

hed paper

.

5862Ă444ĂGBăăăSubject to technical modifications.