21

5603 884 - 04

Vitoflex 300-UF Service & Maintenance

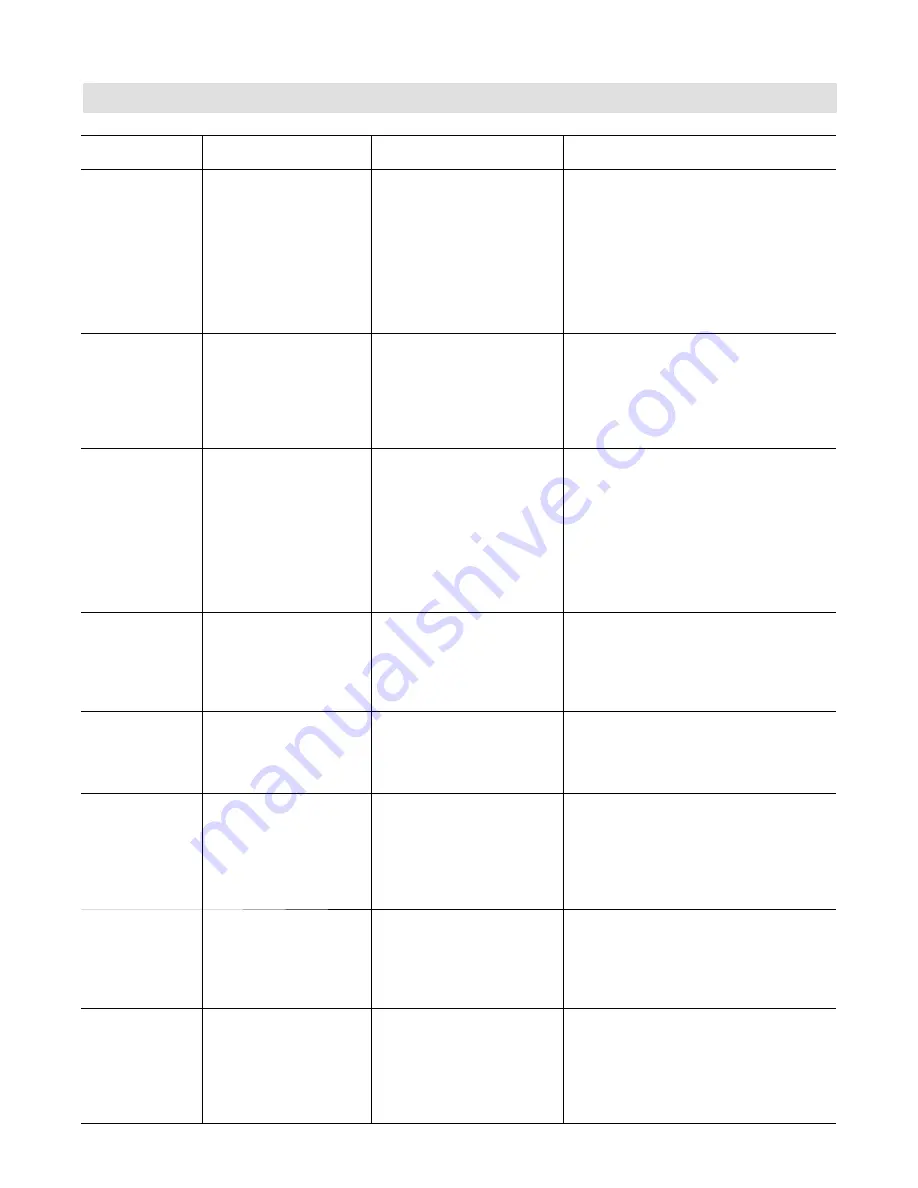

System Faults

Text for error

shown on display

Indicator

Possible cause

Check / remedy

Excess

temperature, lack

of water, water

pressure

- Fixed high limit at the

top of the boiler (N21)

- Low water cut off (N22)

- Pressure monitor (N23)

- Incorrect set-point adjusted

on the control module

(either the boiler set-point

temperature or the cycle

for “In-feed Auger” is too

high)

- Defective component

..

(pump or valve)

- Sudden output drop to zero

- Why couldn’t the heat be transferred?

- Check the boiler pump and mixing valve

- Reduce the cycle for “In-feed Auger”

(see the Installation and Operating

Instructions)

- Take off the protective cap from the

fixed high limit and press the reset

button (this is only possible at boiler

temperatures less than 158°F (70°C)

- Acknowledge in Screen 2

Underfeed pipe

is hot

- Temperature sensor

on the in-feed auger

(B02)

- Power failure

- Consequent malfunction,

caused by excess temperature

- Light barriers for ember

monitoring system are soiled

- Cycle for “Sustain Embers”

is set too low

- Call a qualified electrician

- Check light barriers at the embers

- Set cycle higher for “Sustain Embers”

(see the Installation and Operating

Instructions)

- Acknowledge in Screen 2

Malfunction,

excess pressure

in combustion

chamber

- Negative pressure

monitoring assembly

on the combustion

chamber (N70)

- Flue gas exhaust blower is

broken

- Boiler is very soiled

- Ash container has been

removed or is mounted

incorrectly

- Check flue gas exhaust blower

- Clean boiler

- Check mounting of ash container

- Reset negative pressure monitoring

assembly (N70) (on the fixed high limit

for the combustion chamber, take off

the protective cap and press the reset

button - this is only possible at boiler

temperatures less than 158°F (70°C)

- Acknowledge in Screen 2

Malfunction,

low pressure

measured in

combustion

chamber

- Negative pressure

gauge (B70)

- Flue gas exhaust blower is

broken

- Boiler is very soiled

- Ash container has been

removed or is mounted

incorrectly

- Check flue gas exhaust blower

- Clean boiler

- Check mounting of ash container

- Acknowledge in Screen 2

Malfunction,

measurement

of combustion

chamber negative

pressure

- Negative pressure

gauge (B70)

- Flue gas exhaust blower is

broken

- Boiler is very soiled

- Check flue gas exhaust blower

- Clean boiler

- Acknowledge in Screen 2

Malfunction,

frequency

converter for

flue gas exhaust

blower

- Frequency converter for

flue gas exhaust blower

(U1)

- Check the error

indication on the

frequency converter

in the control cabinet

- Overload of flue gas

exhaust blower motor (M1)

- Turn off main switch

- Check flue gas exhaust blower

for smooth running

- Acknowledge in Screen 2

Malfunction,

frequency

converter for

Primary air

blower

- Frequency converter for

primary air blower (U12)

- Check the error

indication on the

frequency converter in

the control cabinet

- Overload of one of the

Primary air blower motors

(M12.1, M12.2, and

Primary -3 blower: M12.3)

- Turn off main switch

- Check primary air blower for smooth

running

- Acknowledge in Screen 2

Malfunction,

frequency

converter for

Secondary air

blower

- Frequency converter for

secondary air blower

(U13)

- Check the error

indication on the

frequency converter

in the control cabinet

- Overload of the Secondary

air blower motor (M13)

- Turn off main switch

- Check secondary air blower for smooth

running

- Acknowledge in Screen 2

Troubleshooting Guide