Series 751 FireLock® Alarm Check Valve

8

IMPORTANT INSTALLATION

INFORMATION

1.

For proper operation and approval, the Series 751 Alarm Check

Valve must be installed in accordance with the specific trim diagrams

included in the shipment.

NOTE:

Victaulic provides specific trim dia-

grams for vertical and horizontal installations.

2.

Before installing the Series 751 Alarm Check Valve, flush the

water supply piping thoroughly to remove all foreign material.

3.

Series 751 Alarm Check Valves

MUST NOT

be located in an area

where the valve can be exposed to freezing temperatures. In addition,

the Series 751 Alarm Check Valve

MUST NOT

be located in an area

where physical damage may occur.

4.

It is the owner’s responsibility to confirm material compatibility of

the Series 751 Alarm Check Valve, trim, and associated accessories

when a corrosive environment or contaminated water is present.

5.

The Victaulic Series 752 Retard Chamber should be installed in

variable pressure installations.

NOTE:

Victaulic provides specific trim

drawings for installations that involve a Series 752 Retard Chamber.

6.

The Series 752V Retard Vent Kit is required any time an air break

is needed above the retard chamber. In addition, the Series 752V

Retard Vent Kit is required if multiple valves are tied into one water

motor alarm and a check valve isolates each line. Refer to the drawing

above.

7.

Series 751 Alarm Check Valves can be installed in the vertical

position with the arrow on the body pointing upward. The arrow on the

swing check valve in the bypass line must point upward.

8.

When installed horizontally, the cover plate must face up-

ward. The arrow on the swing check valve in the bypass line must

match the direction of the water flow.

9.

When the Series 751 Alarm Check Valve is used with a water

motor alarm, it is recommended that the valve contain an uninterrupted,

low-pressure alarm that is installed on the piston charge line down-

stream of the check valve.

VALVE/TRIM INSTALLATION

1.

Make sure trim drawings match system requirements. Refer to

page 7 for the listing.

2.

Remove all plastic caps and foam spacers from the valve.

3.

Apply a small amount of pipe joint compound or Teflon* tape to

the external threads of all threaded pipe connections. DO NOT get any

tape, compound, or other foreign material in the valve body, pipe nip-

ples, or valve openings.

4.

Install the valve, trim, and accessories per the trim drawing.

* Teflon is a registered trademark of the Dupont Company

HYDROSTATIC TESTING

The Victaulic Series 751 Alarm Valve is UL Listed and FM Approved for

a maximum working pressure of 300 psi (2065 kPa) for 1

1

/

2

- 6-inch (40

– 150-mm) sizes and 225 psi (1551 kPa) for the 8-inch (200-mm) size.

The valve is factory tested to 600 psi (4135 kPa) for 1

1

/

2

- 6-inch (40 –

150-mm) sizes and 500 psi (3447 kPa) for the 8-inch (200-mm) size. The

valve can be hydrostatically tested against the clapper at 200 psi (1380

kPa) or 50 psi (345 kPa) above the normal water supply pressure (2-

hour limited time period) for acceptance by the authority having

jurisdiction.

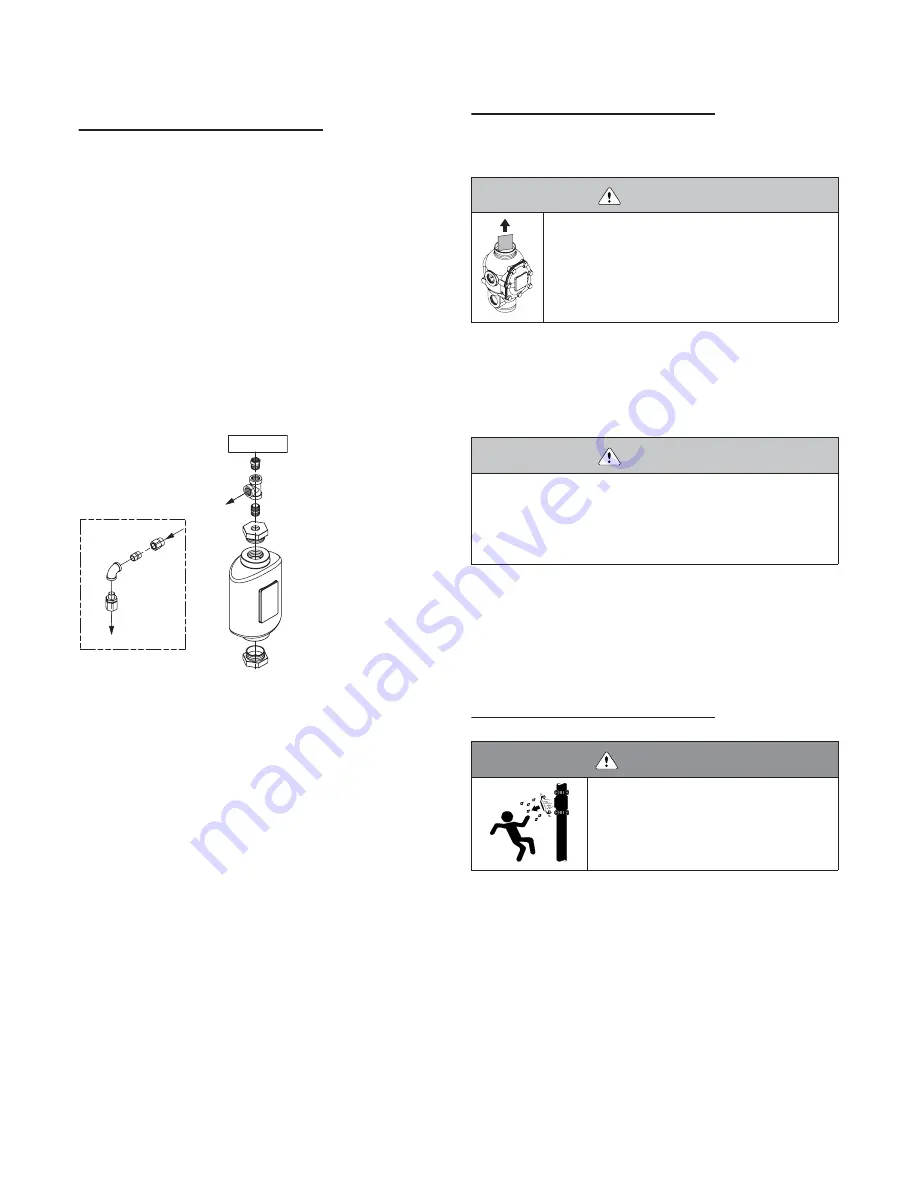

Optional Series 752V

Retard Vent Kit

To Water Motor

Alarm or Optional

Restrictor

Optional Pressure

Switch

Pipe to

Open Drain

CAUTION

• Make sure the foam spacer is removed from inside

the valve body before attempting to install the valve.

Failure to follow this instruction could cause improper

valve operation, resulting in personal injury and/or

property damage.

CAUTION

• Make sure no foreign material gets into the valve body, pipe nip-

ples, or valve openings.

• If using any material other than Teflon tape, use extra caution so

that no material gets into the trim.

Failure to follow these instructions could cause improper valve

operation and/or property damage.

WARNING

• If air testing is required, DO NOT exceed 50-

psi (345-kPa) air pressure.

Failure to follow this instruction could result in

serious personal injury and/or property dam-

age.