E-CART (ELECTRIC CART)

12

Maintenance and repair

T

ROUBLESHOOTING

G

UIDE

--

______

Warning: Before performing any task, always block drive wheel off of the ground.

Consult the factory for problems at time of installation, or for any problems not addressed

below.

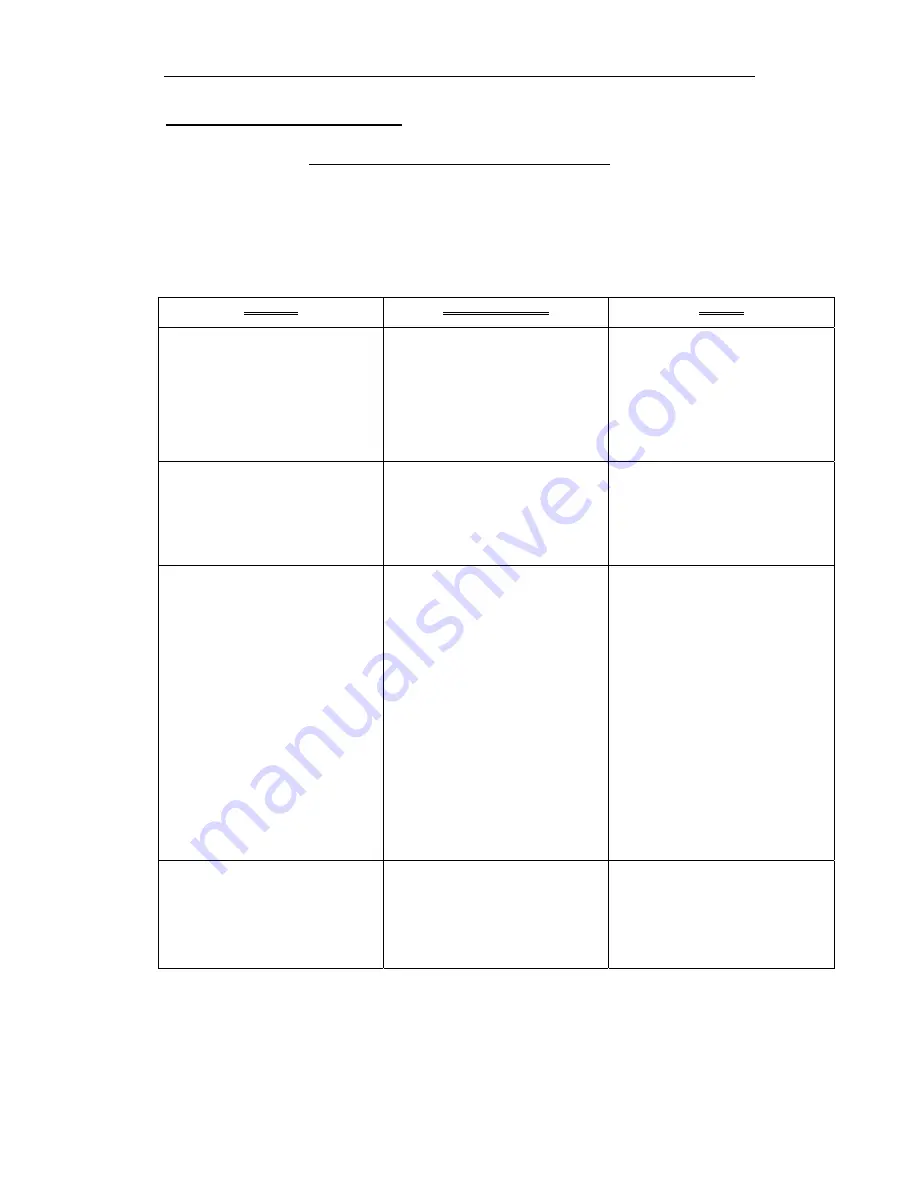

Problem: Possible

cause(s): Action:

Unit doesn’t move when controls are

used.

Battery voltage low (<17)

Problem with motor controller

(check for LED flash code on side

of controller)

Fuse blown

Charge batteries.

Consult diagnostics

page/factory

Remove back shroud and check

fuses (3 fuses).

Unit will not charge

Charger malfunction

Bad batteries

Verify output voltage on charger,

will only get a reading when

connected to batteries; should be

approximately 28 volts.

Load test batteries

Unit will not go forward; reverse

works; belly switch just kills unit

(does not go forward and time out)

Broken wire, or loose connection

Contactor bad, motor controller bad

Locate Pin 2 on Molex connector at

motor controller. Trace wiring to

contactor and verify connection.

When forward is depressed, there

should be 24 volts on this wire

from Molex connector to the

contactor, if not, the motor

controller may be bad; consult

diagnostics page/factory. If 24

volts is present at contactor,

verify ground connection. If

ground is good, remove both wires

and check with ohm meter;

resistance should be

approximately 38 ohms. If it’s

open or zero, the contactor should

be replaced.

Unit will not go reverse; belly switch

works (i.e. when the handle is in

operating range and rotating

throttle in reverse and the belly

switch is hit, the unit moves

forward and times out)

Broken wire, or loose connection,

contactor bad, motor controller

bad

Same as above; except locate Pin 3

on Molex connector on motor

controller…and follow procedure.